Каталог Stellram токарный инструмент - страница 201

Навигация

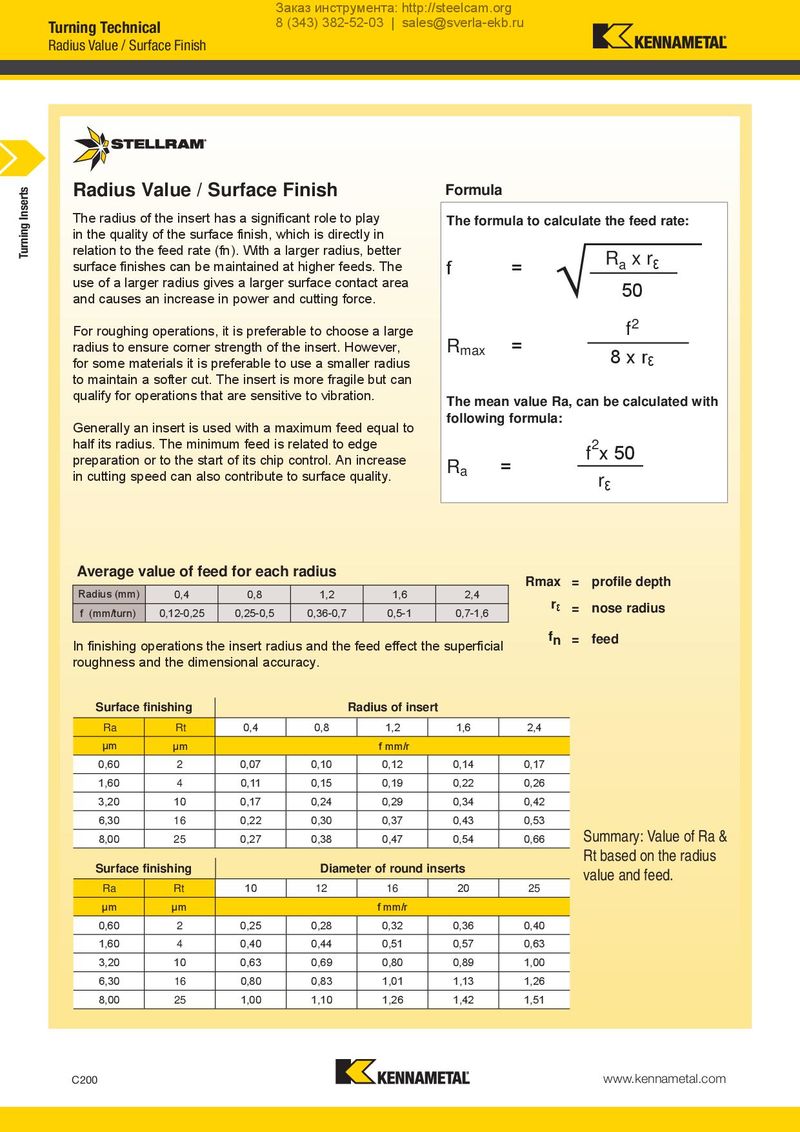

Заказ инструмента: http://steelcam.org Turning Technical 8 (343) 382-52-03 | sales@sverla-ekb.ru Radius Value / Surface Finish Turning Inserts Radius Value / Surface Finish Formula The radius of the insert has a significant role to play The formula to calculate the feed rate: in the quality of the surface finish, which is directly in relation to the feed rate (fn). With a larger radius, better Ra x rε surface finishes can be maintained at higher feeds. The f = use of a larger radius gives a larger surface contact area 50 and causes an increase in power and cutting force. For roughing operations, it is preferable to choose a large f2 radius to ensure corner strength of the insert. However, R max = 8 x rε for some materials it is preferable to use a smaller radius to maintain a softer cut. The insert is more fragile but can qualify for operations that are sensitive to vibration. The mean value Ra, can be calculated with Generally an insert is used with a maximum feed equal to following formula: half its radius. The minimum feed is related to edge f2x 50 preparation or to the start of its chip control. An increase R a = in cutting speed can also contribute to surface quality. rε Average value of feed for each radius Rmax = profile depth Radius (mm) 0,4 0,8 1,2 1,6 2,4 rε f (mm/turn) 0,12-0,25 0,25-0,5 0,36-0,7 0,5-1 0,7-1,6 = nose radius In finishing operations the insert radius and the feed effect the superficial fn = feed roughness and the dimensional accuracy. Surface finishing Radius of insert Ra Rt 0,4 0,8 1,2 1,6 2,4 µm µm f mm/r 0,60 2 0,07 0,10 0,12 0,14 0,17 1,60 4 0,11 0,15 0,19 0,22 0,26 3,20 10 0,17 0,24 0,29 0,34 0,42 6,30 16 0,22 0,30 0,37 0,43 0,53 8,00 25 0,27 0,38 0,47 0,54 0,66 Summary: Value of Ra & Surface finishing Diameter of round inserts Rt based on the radius Ra Rt 10 12 16 20 25 value and feed. µm µm f mm/r 0,60 2 0,25 0,28 0,32 0,36 0,40 1,60 4 0,40 0,44 0,51 0,57 0,63 3,20 10 0,63 0,69 0,80 0,89 1,00 6,30 16 0,80 0,83 1,01 1,13 1,26 8,00 25 1,00 1,10 1,26 1,42 1,51 C200 www.kennametal.com

Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами