Каталог Stellram токарный инструмент - страница 200

Навигация

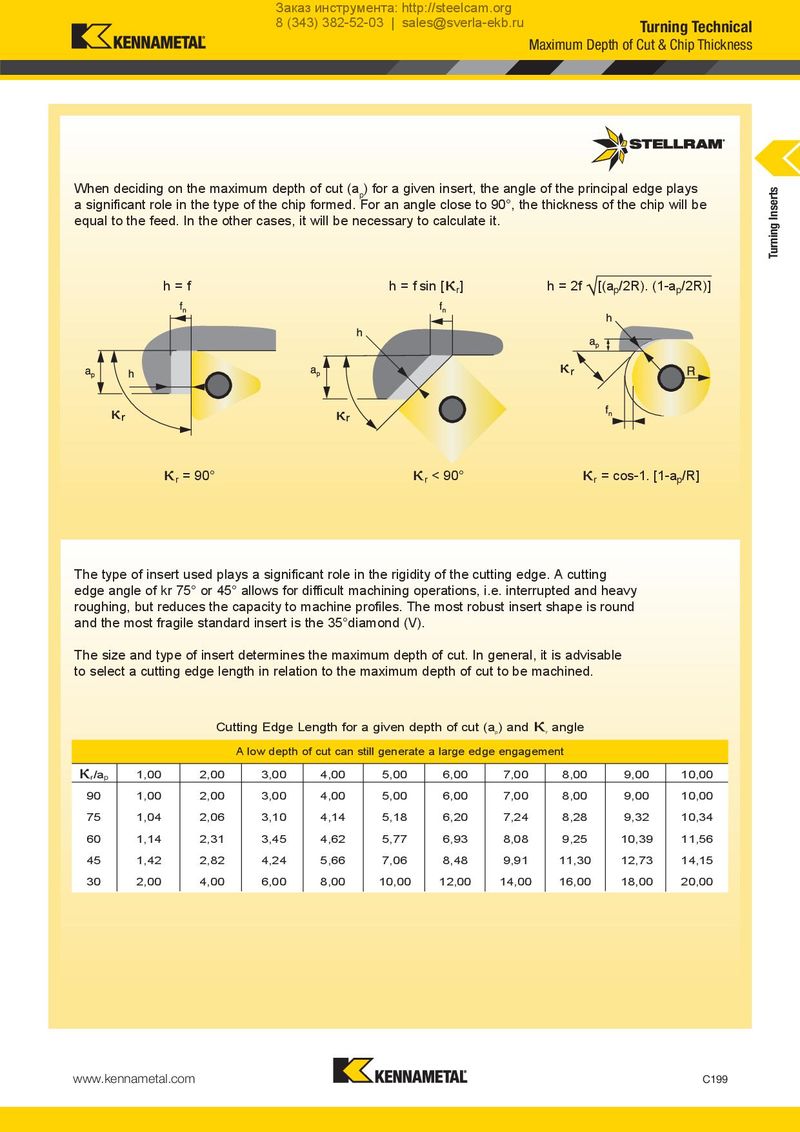

Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru Turning Technical Maximum Depth of Cut & Chip Thickness When deciding on the maximum depth of cut (ap) for a given insert, the angle of the principal edge plays Turning Inserts a significant role in the type of the chip formed. For an angle close to 90°, the thickness of the chip will be equal to the feed. In the other cases, it will be necessary to calculate it. h=f k h = f sin [ r] h = 2f [(ap/2R). (1-ap/2R)] kr = 90° kr < 90° kr = cos-1. [1-ap/R] The type of insert used plays a significant role in the rigidity of the cutting edge. A cutting edge angle of kr 75° or 45° allows for difficult machining operations, i.e. interrupted and heavy roughing, but reduces the capacity to machine profiles. The most robust insert shape is round and the most fragile standard insert is the 35°diamond (V). The size and type of insert determines the maximum depth of cut. In general, it is advisable to select a cutting edge length in relation to the maximum depth of cut to be machined. k Cutting Edge Length for a given depth of cut (ap) and r angle A low depth of cut can still generate a large edge engagement kr/ap 1,00 2,00 3,00 4,00 5,00 6,00 7,00 8,00 9,00 10,00 90 1,00 2,00 3,00 4,00 5,00 6,00 7,00 8,00 9,00 10,00 75 1,04 2,06 3,10 4,14 5,18 6,20 7,24 8,28 9,32 10,34 60 1,14 2,31 3,45 4,62 5,77 6,93 8,08 9,25 10,39 11,56 45 1,42 2,82 4,24 5,66 7,06 8,48 9,91 11,30 12,73 14,15 30 2,00 4,00 6,00 8,00 10,00 12,00 14,00 16,00 18,00 20,00 www.kennametal.com C199

Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами