Каталог Stellram фрез со сменными пластинами - страница 26

Навигация

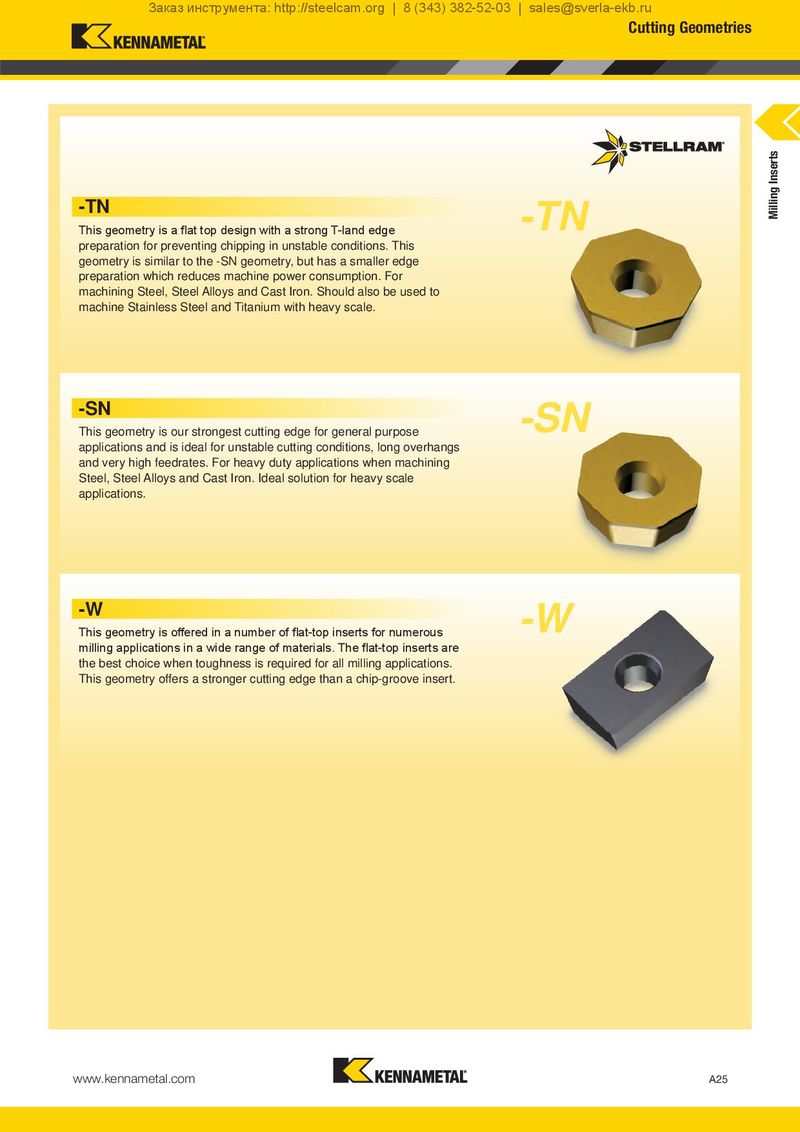

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru Cutting Geometries -TN -TN Milling Inserts This geometry is a flat top design with a strong T-land edge preparation for preventing chipping in unstable conditions. This geometry is similar to the -SN geometry, but has a smaller edge preparation which reduces machine power consumption. For machining Steel, Steel Alloys and Cast Iron. Should also be used to machine Stainless Steel and Titanium with heavy scale. -SN -SN This geometry is our strongest cutting edge for general purpose applications and is ideal for unstable cutting conditions, long overhangs and very high feedrates. For heavy duty applications when machining Steel, Steel Alloys and Cast Iron. Ideal solution for heavy scale applications. -W -W This geometry is offered in a number of flat-top inserts for numerous milling applications in a wide range of materials. The flat-top inserts are the best choice when toughness is required for all milling applications. This geometry offers a stronger cutting edge than a chip-groove insert. www.kennametal.com A25

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы