Каталог Stellram фрез со сменными пластинами - страница 256

Навигация

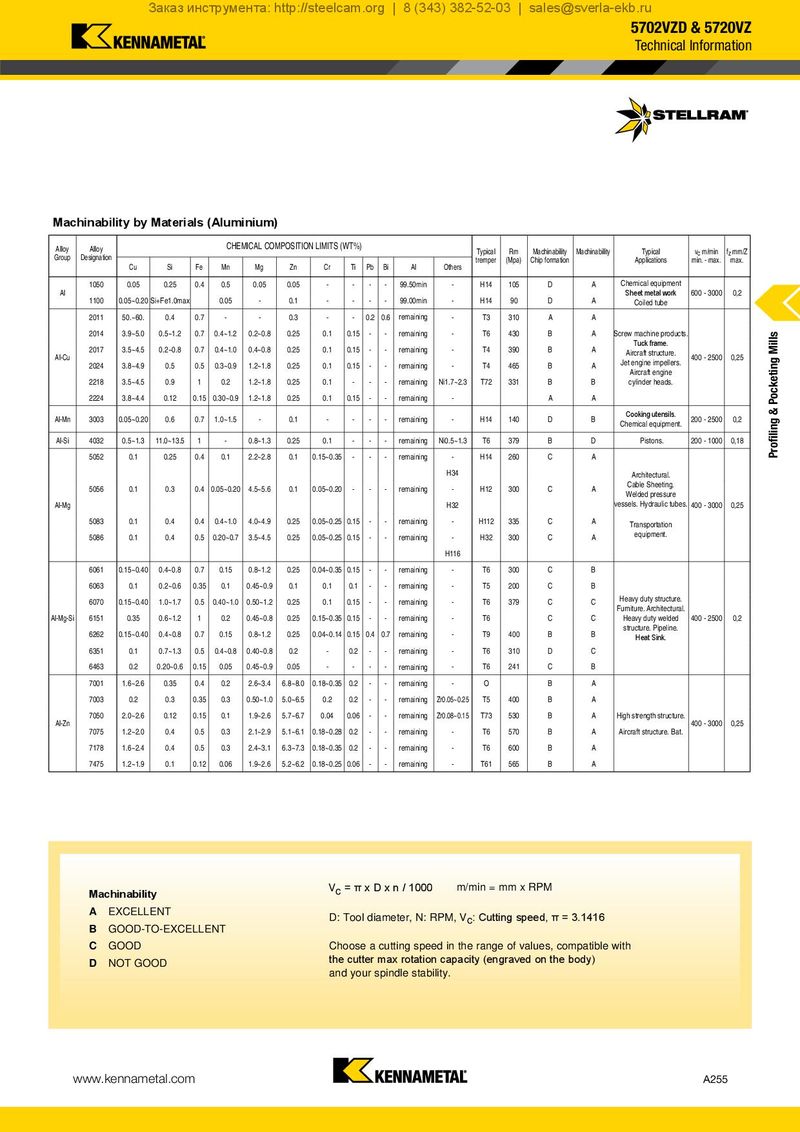

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 5702VZD & 5720VZ Technical Information Machinability by Materials (Aluminium) Alloy Alloy CHEMICAL COMPOSITION LIMITS (WT%) Typical Rm Machinability Machinability Typical vc m/min fz mm/Z Group Designation tremper (Mpa) Chip formation Applications min. - max. max. Cu Si Fe Mn Mg Zn Cr Ti Pb Bi Al Others 1050 0.05 0.25 0.4 0.5 0.05 0.05 - - - - 99.50min - H14 105 D A Chemical equipment Al Sheet metal work 600 - 3000 0,2 1100 0.05~0.20 Si+Fe1.0max 0.05 - 0.1 - - - - 99.00min - H14 90 D A Coiled tube 2011 50.~60. 0.4 0.7 - - 0.3 - - 0.2 0.6 remaining - T3 310 A A 2014 3.9~5.0 0.5~1.2 0.7 0.4~1.2 0.2~0.8 0.25 0.1 0.15 - - remaining - T6 430 B A Screw machine products. Profiling & Pocketing Mills 2017 3.5~4.5 0.2~0.8 0.7 0.4~1.0 0.4~0.8 0.25 0.1 0.15 - - remaining - T4 390 B A Tuck frame. Al-Cu Aircraft structure. 400 - 2500 0,25 2024 3.8~4.9 0.5 0.5 0.3~0.9 1.2~1.8 0.25 0.1 0.15 - - remaining - T4 465 B A Jet engine impellers. Aircraft engine 2218 3.5~4.5 0.9 1 0.2 1.2~1.8 0.25 0.1 - - - remaining Ni1.7~2.3 T72 331 B B cylinder heads. 2224 3.8~4.4 0.12 0.15 0.30~0.9 1.2~1.8 0.25 0.1 0.15 - - remaining - A A Al-Mn 3003 0.05~0.20 0.6 0.7 1.0~1.5 - 0.1 - - - - remaining - H14 140 D B Cooking utensils. 200 - 2500 0,2 Chemical equipment. Al-Si 4032 0.5~1.3 11.0~13.5 1 - 0.8~1.3 0.25 0.1 - - - remaining Ni0.5~1.3 T6 379 B D Pistons. 200 - 1000 0,18 5052 0.1 0.25 0.4 0.1 2.2~2.8 0.1 0.15~0.35 - - - remaining - H14 260 C A H34 Architectural. 5056 0.1 0.3 0.4 0.05~0.20 4.5~5.6 0.1 0.05~0.20 - - - remaining - H12 300 C A Cable Sheeting. Welded pressure Al-Mg H32 vessels. Hydraulic tubes. 400 - 3000 0,25 5083 0.1 0.4 0.4 0.4~1.0 4.0~4.9 0.25 0.05~0.25 0.15 - - remaining - H112 335 C A Transportation 5086 0.1 0.4 0.5 0.20~0.7 3.5~4.5 0.25 0.05~0.25 0.15 - - remaining - H32 300 C A equipment. H116 6061 0.15~0.40 0.4~0.8 0.7 0.15 0.8~1.2 0.25 0.04~0.35 0.15 - - remaining - T6 300 C B 6063 0.1 0.2~0.6 0.35 0.1 0.45~0.9 0.1 0.1 0.1 - - remaining - T5 200 C B 6070 0.15~0.40 1.0~1.7 0.5 0.40~1.0 0.50~1.2 0.25 0.1 0.15 - - remaining - T6 379 C C Heavy duty structure. Furniture. Architectural. Al-Mg-Si 6151 0.35 0.6~1.2 1 0.2 0.45~0.8 0.25 0.15~0.35 0.15 - - remaining - T6 C C Heavy duty welded 400 - 2500 0,2 6262 0.15~0.40 0.4~0.8 0.7 0.15 0.8~1.2 0.25 0.04~0.14 0.15 0.4 0.7 remaining - T9 400 B B structure. Pipeline. Heat Sink. 6351 0.1 0.7~1.3 0.5 0.4~0.8 0.40~0.8 0.2 - 0.2 - - remaining - T6 310 D C 6463 0.2 0.20~0.6 0.15 0.05 0.45~0.9 0.05 - - - - remaining - T6 241 C B 7001 1.6~2.6 0.35 0.4 0.2 2.6~3.4 6.8~8.0 0.18~0.35 0.2 - - remaining - O B A 7003 0.2 0.3 0.35 0.3 0.50~1.0 5.0~6.5 0.2 0.2 - - remaining Zr0.05~0.25 T5 400 B A 7050 2.0~2.6 0.12 0.15 0.1 1.9~2.6 5.7~6.7 0.04 0.06 - - remaining Zr0.08~0.15 T73 530 B A High strength structure. Al-Zn 400 - 3000 0,25 7075 1.2~2.0 0.4 0.5 0.3 2.1~2.9 5.1~6.1 0.18~0.28 0.2 - - remaining - T6 570 B A Aircraft structure. Bat. 7178 1.6~2.4 0.4 0.5 0.3 2.4~3.1 6.3~7.3 0.18~0.35 0.2 - - remaining - T6 600 B A 7475 1.2~1.9 0.1 0.12 0.06 1.9~2.6 5.2~6.2 0.18~0.25 0.06 - - remaining - T61 565 B A Machinability Vc = π x D x n / 1000 m/min = mm x RPM A EXCELLENT D: Tool diameter, N: RPM, Vc: Cutting speed, π = 3.1416 B GOOD-TO-EXCELLENT C GOOD Choose a cutting speed in the range of values, compatible with D NOT GOOD the cutter max rotation capacity (engraved on the body) and your spindle stability. www.kennametal.com A255

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы