Каталог Stellram фрез со сменными пластинами - страница 164

Навигация

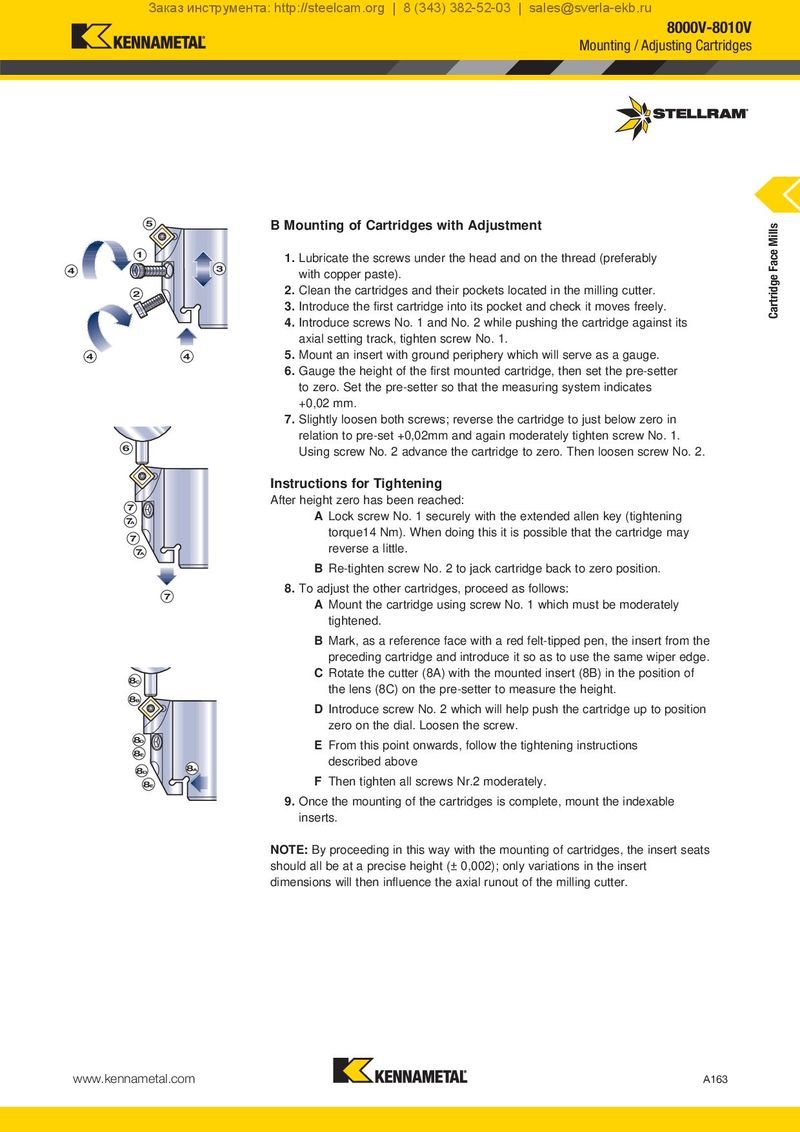

Заказ инструмента: http://steelcam.org | 8 (343) 382-52-03 | sales@sverla-ekb.ru 8000V-8010V Mounting / Adjusting Cartridges 5 B Mounting of Cartridges with Adjustment Cartridge Face Mills 1 1. Lubricate the screws under the head and on the thread (preferably 4 3 with copper paste). 2 2. Clean the cartridges and their pockets located in the milling cutter. 3. Introduce the first cartridge into its pocket and check it moves freely. 4. Introduce screws No. 1 and No. 2 while pushing the cartridge against its axial setting track, tighten screw No. 1. 4 4 5. Mount an insert with ground periphery which will serve as a gauge. 6. Gauge the height of the first mounted cartridge, then set the pre-setter to zero. Set the pre-setter so that the measuring system indicates +0,02 mm. 7. Slightly loosen both screws; reverse the cartridge to just below zero in relation to pre-set +0,02mm and again moderately tighten screw No. 1. 6 Using screw No. 2 advance the cartridge to zero. Then loosen screw No. 2. Instructions for Tightening 7 After height zero has been reached: 7A A Lock screw No. 1 securely with the extended allen key (tightening 7 torque14 Nm). When doing this it is possible that the cartridge may 7A reverse a little. B Re-tighten screw No. 2 to jack cartridge back to zero position. 7 8. To adjust the other cartridges, proceed as follows: A Mount the cartridge using screw No. 1 which must be moderately tightened. B Mark, as a reference face with a red felt-tipped pen, the insert from the preceding cartridge and introduce it so as to use the same wiper edge. 8C C Rotate the cutter (8A) with the mounted insert (8B) in the position of the lens (8C) on the pre-setter to measure the height. 8B D Introduce screw No. 2 which will help push the cartridge up to position zero on the dial. Loosen the screw. 8D E From this point onwards, follow the tightening instructions 8E described above 8D 8A 8E F Then tighten all screws Nr.2 moderately. 9. Once the mounting of the cartridges is complete, mount the indexable inserts. NOTE: By proceeding in this way with the mounting of cartridges, the insert seats should all be at a precise height (± 0,002); only variations in the insert dimensions will then influence the axial runout of the milling cutter. www.kennametal.com A163

Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram токарный инструмент

Каталог Stellram токарный инструмент Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы