Общий каталог SGS 2018 - страница 353

Навигация

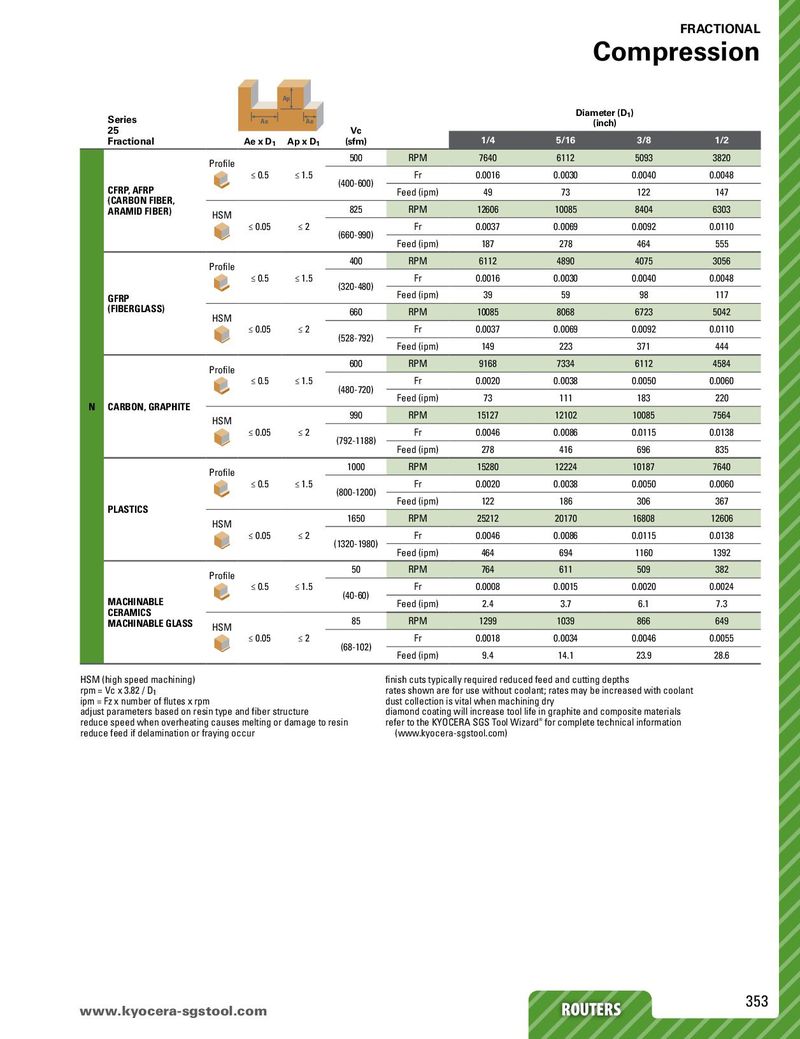

FRACTIONAL Compression Ap Series Diameter (D1) Ae Ae (inch) 25 Vc Fractional Ae x D1 Ap x D1 (sfm) 1/4 5/16 3/8 1/2 Profile 500 RPM 7640 6112 5093 3820 ≤ 0.5 ≤ 1.5 (400-600) Fr 0.0016 0.0030 0.0040 0.0048 CFRP, AFRP Feed (ipm) 49 73 122 147 (CARBON FIBER, 825 RPM 12606 10085 8404 6303 ARAMID FIBER) HSM ≤ 0.05 ≤2 (660-990) Fr 0.0037 0.0069 0.0092 0.0110 Feed (ipm) 187 278 464 555 Profile 400 RPM 6112 4890 4075 3056 ≤ 0.5 ≤ 1.5 (320-480) Fr 0.0016 0.0030 0.0040 0.0048 GFRP Feed (ipm) 39 59 98 117 (FIBERGLASS) 660 RPM 10085 8068 6723 5042 HSM ≤ 0.05 ≤2 (528-792) Fr 0.0037 0.0069 0.0092 0.0110 Feed (ipm) 149 223 371 444 Profile 600 RPM 9168 7334 6112 4584 ≤ 0.5 ≤ 1.5 (480-720) Fr 0.0020 0.0038 0.0050 0.0060 N CARBON, GRAPHITE Feed (ipm) 73 111 183 220 HSM 990 RPM 15127 12102 10085 7564 ≤ 0.05 ≤2 (792-1188) Fr 0.0046 0.0086 0.0115 0.0138 Feed (ipm) 278 416 696 835 Profile 1000 RPM 15280 12224 10187 7640 ≤ 0.5 ≤ 1.5 (800-1200) Fr 0.0020 0.0038 0.0050 0.0060 PLASTICS Feed (ipm) 122 186 306 367 HSM 1650 RPM 25212 20170 16808 12606 ≤ 0.05 ≤2 (1320-1980) Fr 0.0046 0.0086 0.0115 0.0138 Feed (ipm) 464 694 1160 1392 Profile 50 RPM 764 611 509 382 ≤ 0.5 ≤ 1.5 (40-60) Fr 0.0008 0.0015 0.0020 0.0024 MACHINABLE Feed (ipm) 2.4 3.7 6.1 7.3 CERAMICS 85 RPM 1299 1039 866 649 MACHINABLE GLASS HSM ≤ 0.05 ≤2 (68-102) Fr 0.0018 0.0034 0.0046 0.0055 Feed (ipm) 9.4 14.1 23.9 28.6 HSM (high speed machining) finish cuts typically required reduced feed and cutting depths rpm = Vc x 3.82 / D1 rates shown are for use without coolant; rates may be increased with coolant ipm = Fz x number of flutes x rpm dust collection is vital when machining dry adjust parameters based on resin type and fiber structure diamond coating will increase tool life in graphite and composite materials reduce speed when overheating causes melting or damage to resin refer to the KYOCERA SGS Tool Wizard® for complete technical information reduce feed if delamination or fraying occur (www.kyocera-sgstool.com) www.kyocerRaO-sUgTsEtRoSol.com ROUTERS 353

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском