Общий каталог SGS 2018 - страница 262

Навигация

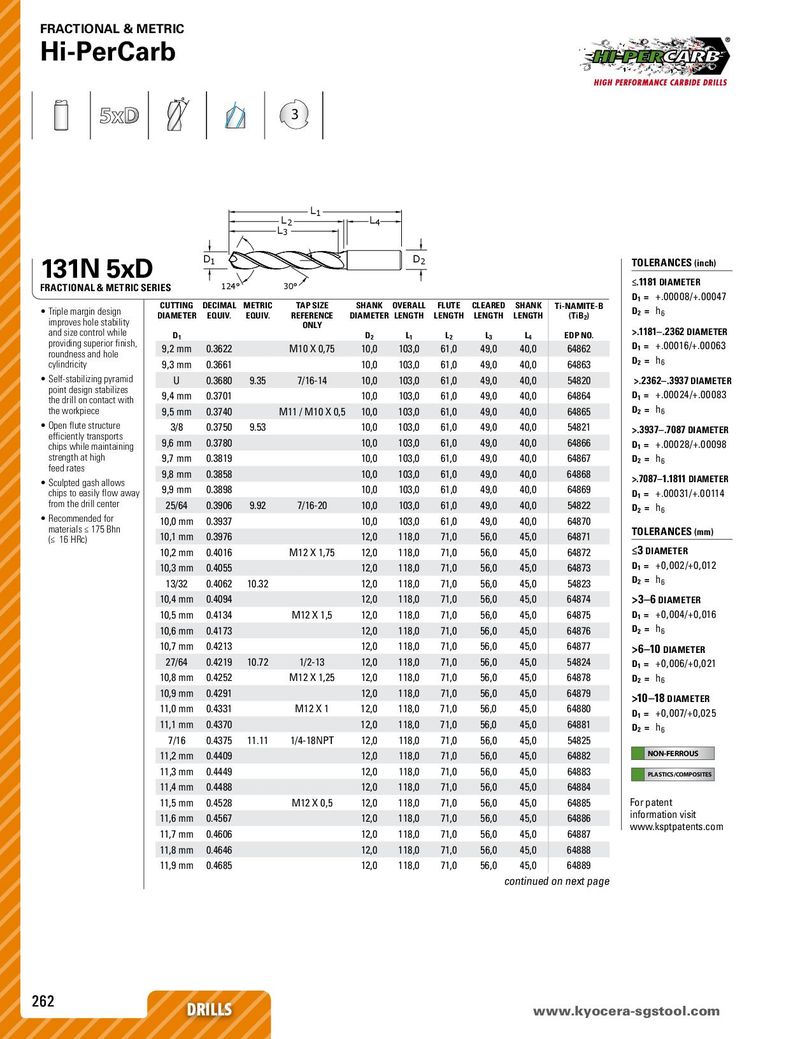

FRACTIONAL & METRIC Hi-PerCarb 3 L2 L1 L4 L3 131N 5xD D1 D2 TOLERANCES (inch) FRACTIONAL & METRIC SERIES 124° 30° ≤.1181 DIAMETER D1 = +.00008/+.00047 • Triple margin design CUTTING DECIMAL METRIC TAP SIZE SHANK OVERALL FLUTE CLEARED SHANK Ti-NAMITE-B D2 = h6 improves hole stability DIAMETER EQUIV. EQUIV. REFERENCE DIAMETER LENGTH LENGTH LENGTH LENGTH (TiB2) and size control while ONLY >.1181–.2362 DIAMETER providing superior finish, D1 D2 L1 L2 L3 L4 EDP NO. roundness and hole 9,2 mm 0.3622 M10 X 0,75 10,0 103,0 61,0 49,0 40,0 64862 D1 = +.00016/+.00063 cylindricity 9,3 mm 0.3661 10,0 103,0 61,0 49,0 40,0 64863 D2 = h6 • Self-stabilizing pyramid U 0.3680 9.35 7/16-14 10,0 103,0 61,0 49,0 40,0 54820 >.2362–.3937 DIAMETER point design stabilizes 9,4 mm 0.3701 10,0 103,0 61,0 49,0 40,0 64864 D1 = +.00024/+.00083 the drill on contact with h6 the workpiece 9,5 mm 0.3740 M11 / M10 X 0,5 10,0 103,0 61,0 49,0 40,0 64865 D2 = • Open flute structure 3/8 0.3750 9.53 10,0 103,0 61,0 49,0 40,0 54821 >.3937–.7087 DIAMETER efficiently transports 9,6 mm 0.3780 10,0 103,0 61,0 49,0 40,0 64866 D1 = +.00028/+.00098 chips while maintaining strength at high 9,7 mm 0.3819 10,0 103,0 61,0 49,0 40,0 64867 D2 = h6 feed rates 9,8 mm 0.3858 10,0 103,0 61,0 49,0 40,0 64868 • Sculpted gash allows >.7087–1.1811 DIAMETER chips to easily flow away 9,9 mm 0.3898 10,0 103,0 61,0 49,0 40,0 64869 D1 = +.00031/+.00114 from the drill center 25/64 0.3906 9.92 7/16-20 10,0 103,0 61,0 49,0 40,0 54822 D2 = h6 • Recommended for 10,0 mm 0.3937 10,0 103,0 61,0 49,0 40,0 64870 materials ≤ 175 Bhn 10,1 mm 0.3976 12,0 118,0 71,0 56,0 45,0 64871 TOLERANCES (mm) (≤ 16 HRc) 10,2 mm 0.4016 M12 X 1,75 12,0 118,0 71,0 56,0 45,0 64872 ≤3 DIAMETER 10,3 mm 0.4055 12,0 118,0 71,0 56,0 45,0 64873 D1 = + 0, 0 0 2 /+ 0, 012 13/32 0.4062 10.32 12,0 118,0 71,0 56,0 45,0 54823 D2 = h6 10,4 mm 0.4094 12,0 118,0 71,0 56,0 45,0 64874 >3–6 DIAMETER 10,5 mm 0.4134 M12 X 1,5 12,0 118,0 71,0 56,0 45,0 64875 D1 = +0,004/+0,016 10,6 mm 0.4173 12,0 118,0 71,0 56,0 45,0 64876 D2 = h6 10,7 mm 0.4213 12,0 118,0 71,0 56,0 45,0 64877 >6–10 DIAMETER 27/64 0.4219 10.72 1/2-13 12,0 118,0 71,0 56,0 45,0 54824 D1 = +0,006/+0,021 10,8 mm 0.4252 M12 X 1,25 12,0 118,0 71,0 56,0 45,0 64878 D2 = h6 10,9 mm 0.4291 12,0 118,0 71,0 56,0 45,0 64879 >10–18 DIAMETER 11,0 mm 0.4331 M12 X 1 12,0 118,0 71,0 56,0 45,0 64880 D1 = +0,007/+0,025 11,1 mm 0.4370 12,0 118,0 71,0 56,0 45,0 64881 D2 = h6 7/16 0.4375 11.11 1/4-18NPT 12,0 118,0 71,0 56,0 45,0 54825 11,2 mm 0.4409 12,0 118,0 71,0 56,0 45,0 64882 NON-FERROUS 11,3 mm 0.4449 12,0 118,0 71,0 56,0 45,0 64883 PLASTICS/COMPOSITES 11,4 mm 0.4488 12,0 118,0 71,0 56,0 45,0 64884 11,5 mm 0.4528 M12 X 0,5 12,0 118,0 71,0 56,0 45,0 64885 For patent 11,6 mm 0.4567 12,0 118,0 71,0 56,0 45,0 64886 information visit 11,7 mm 0.4606 12,0 118,0 71,0 56,0 45,0 64887 www.ksptpatents.com 11,8 mm 0.4646 12,0 118,0 71,0 56,0 45,0 64888 11,9 mm 0.4685 12,0 118,0 71,0 56,0 45,0 64889 continued on next page 262 DRILLS www.kDyRoIcLeLrSa-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском