Каталог SGS микро инструмент 2021 - страница 133

Навигация

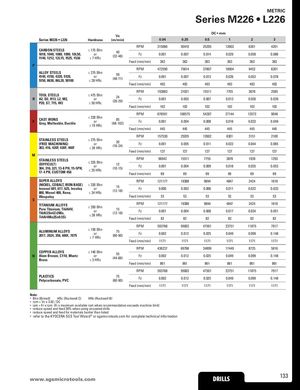

METRIC Series M226 • L226 DC • mm Vc Series M226 • L226 Hardness (m/min) 0.04 0.25 0.5 1 2 3 RPM 315060 50410 25205 12602 6301 4201 CARBON STEELS ≤ 175 Bhn1018, 1040, 1080, 1090, 10L50,or1140, 1212, 12L15, 1525, 1536≤ 7 HRc40(32-48)Fz0.0010.0070.0140.0290.058 0.086 Feed (mm/min) 363 363 363 363 363 363 P RPM 472590 75614 37807 18904 9452 6301 ALLOY STEELS4140, 4150, 4320, 5120,5150, 8630, 86L20, 50100≤ 275 Bhnor≤ 28 HRc59(48-71)Fz0.001 0.007 0.013 0.026 0.052 0.078 Feed (mm/min) 493 493 493 493 493 493 RPM 193883 31021 15511 7755 3878 2585 TOOL STEELSHA2, D2, H13, L2, M2,P20, S7, T15, W2≤ 475 Bhnor≤ 50 HRc24(20-29)Fz 0.001 0.003 0.007 0.013 0.026 0.039 Feed (mm/min) 102 102 102 102 102 102 RPM 678591 108575 54287 27144 13572 9048 K CAST IRONSGray, Malleable, Ductile≤ 220 Bhnor≤ 19 HRc 85(68-102) Fz 0.001 0.004 0.008 0.016 0.033 0.049 Feed (mm/min) 445 445 445 445 445 445 RPM 157530 25205 12602 6301 3151 2100 STAINLESS STEELS(FREE MACHINING)303, 416, 420F, 430F, 440F≤ 275 Bhnor≤ 28 HRc20(16-24)Fz0.001 0.005 0.011 0.022 0.044 0.065 Feed (mm/min) 137 137 137 137 137 137 M STAINLESS STEELS(DIFFICULT)304, 316, 321, 13-8 PH, 15-5PH,17-4 PH, CUSTOM 450≤ 325 Bhnor≤ 35 HRcRPM9694212(10-15)Fz0.001Feed (mm/min)69155110.0046977550.0096938780.0186919390.0356912930.05369 SUPER ALLOYS RPM 121177 19388 9694 4847 2424 1616 (NICKEL, COBALT, IRON BASE) ≤ 320 BhnInconel 601, 617, 625, Incoloyor800, Monel 400, Rene,≤ 34 HRc15(12-18)Fz0.0000.0030.0060.0110.022 0.033 Waspaloy Feed (mm/min) 53 53 53 53 53 53 S TITANIUM ALLOYSPure Titanium, Ti6Al4V,Ti6Al2Sn4Zr2Mo,Ti4Al4Mo2Sn0.5SiRPM 121177 19388≤ 350 Bhnor≤ 38 HRc15(12-18)Fz0.0010.004Feed (mm/min)828296940.0088248470.0178224240.0348216160.05182 RPM 593768 95003 47501 23751 11875 7917 ALUMINUM ALLOYS2017, 2024, 356, 6061, 7075≤ 150 Bhnor≤ 7 HRc75(60-90)Fz 0.002 0.012 0.025 0.049 0.099 0.148 Feed (mm/min) 1171 1171 1171 1171 1171 1171 RPM 436237 69798 34899 17449 8725 5816 COPPER ALLOYSNAlum Bronze, C110, MuntzBrass≤ 140 Bhnor≤ 3 HRc55(44-66)Fz 0.002 0.012 0.025 0.049 0.099 0.148 Feed (mm/min) 861 861 861 861 861 861 RPM 593768 95003 47501 23751 11875 7917 PLASTICSPolycarbonate, PVC 75(60-90) Fz 0.002 0.012 0.025 0.049 0.099 0.148 Feed (mm/min) 1171 1171 1171 1171 1171 1171 Note: • Bhn (Brinell) HRc (Rockwell C) HRb (Rockwell B) • rpm = Vc x 3.82 / DC • ipm = Fr x rpm (Fr x maximum available rpm when recommendation exceeds machine limit) • reduce speed and feed 30% when using uncoated drills • reduce speed and feed for materials harder than listed • refer to the KYOCERA SGS Tool Wizard® or sgsmicrotools.com for complete technical information www.sgsmicrDoRtoILoLlSs.com DRILLS 133

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2018

Общий каталог SGS 2018 Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33