Каталог SGS микро инструмент 2021 - страница 131

Навигация

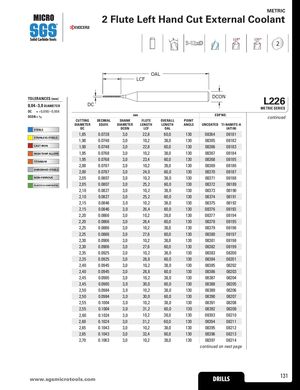

METRIC 2 Flute Left Hand Cut External Coolant 118° 130° 2 OAL LCF TOLERANCES (mm)0,04–3,0 DIAMETER DC DCON L226METRIC SERIES DC = +0,000/–0,008 DCON = h6 mm EDP NO. continued CUTTING DECIMAL SHANK FLUTE OVERALL POINT DIAMETER EQUIV. DIAMETER LENGTH LENGTH ANGLE UNCOATED TI-NAMITE-A STEELS DC DCON LCF OAL (AlTiN) 1,85 0.0728 3,0 22,8 60,0 130 08364 08181 STAINLESS STEELS 1,90 0.0748 3,0 10,2 38,0 130 08365 08182 CAST IRON 1,90 0.0748 3,0 22,8 60,0 130 08366 08183 HIGH TEMP ALLOYS 1,95 0.0768 3,0 10,2 38,0 130 08367 08184 1,95 0.0768 3,0 23,4 60,0 130 08368 08185 TITANIUM 2,00 0.0787 3,0 10,2 38,0 130 08369 08186 HARDENED STEELS 2,00 0.0787 3,0 24,0 60,0 130 08370 08187 NON-FERROUS 2,05 0.0807 3,0 10,2 38,0 130 08371 08188 PLASTICS/COMPOSITES 2,05 0.0807 3,0 25,2 60,0 130 08372 08189 2,10 0.0827 3,0 10,2 38,0 130 08373 08190 2,10 0.0827 3,0 25,2 60,0 130 08374 08191 2,15 0.0846 3,0 10,2 38,0 130 08375 08192 2,15 0.0846 3,0 26,4 60,0 130 08376 08193 2,20 0.0866 3,0 10,2 38,0 130 08377 08194 2,20 0.0866 3,0 26,4 60,0 130 08378 08195 2,25 0.0886 3,0 10,2 38,0 130 08379 08196 2,25 0.0886 3,0 27,6 60,0 130 08380 08197 2,30 0.0906 3,0 10,2 38,0 130 08381 08198 2,30 0.0906 3,0 27,6 60,0 130 08382 08199 2,35 0.0925 3,0 10,2 38,0 130 08383 08200 2,35 0.0925 3,0 28,8 60,0 130 08384 08201 2,40 0.0945 3,0 10,2 38,0 130 08385 08202 2,40 0.0945 3,0 28,8 60,0 130 08386 08203 2,45 0.0965 3,0 10,2 38,0 130 08387 08204 2,45 0.0965 3,0 30,0 60,0 130 08388 08205 2,50 0.0984 3,0 10,2 38,0 130 08389 08206 2,50 0.0984 3,0 30,0 60,0 130 08390 08207 2,55 0.1004 3,0 10,2 38,0 130 08391 08208 2,55 0.1004 3,0 31,2 60,0 130 08392 08209 2,60 0.1024 3,0 10,2 38,0 130 08393 08210 2,60 0.1024 3,0 31,2 60,0 130 08394 08211 2,65 0.1043 3,0 10,2 38,0 130 08395 08212 2,65 0.1043 3,0 32,4 60,0 130 08396 08213 2,70 0.1063 3,0 10,2 38,0 130 08397 08214 continued on next page www.sgsmicrDoRtoILoLlSs.com DRILLS 131

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2018

Общий каталог SGS 2018 Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33