Каталог SGS микро инструмент 2021 - страница 129

Навигация

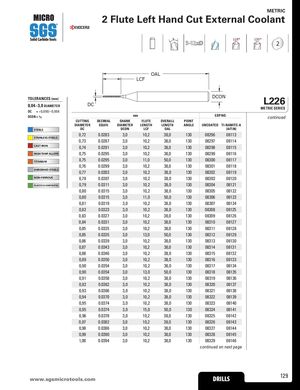

METRIC 2 Flute Left Hand Cut External Coolant 118° 130° 2 OAL LCF TOLERANCES (mm)0,04–3,0 DIAMETER DC DCON L226METRIC SERIES DC = +0,000/–0,008 DCON = h6 mm EDP NO. continued CUTTING DECIMAL SHANK FLUTE OVERALL POINT DIAMETER EQUIV. DIAMETER LENGTH LENGTH ANGLE UNCOATED TI-NAMITE-A STEELS DC DCON LCF OAL (AlTiN) 0,72 0.0283 3,0 10,2 38,0 130 08296 08113 STAINLESS STEELS 0,73 0.0287 3,0 10,2 38,0 130 08297 08114 CAST IRON 0,74 0.0291 3,0 10,2 38,0 130 08298 08115 HIGH TEMP ALLOYS 0,75 0.0295 3,0 10,2 38,0 130 08299 08116 TITANIUM 0,75 0.0295 3,0 11,0 50,0 130 08300 08117 0,76 0.0299 3,0 10,2 38,0 130 08301 08118 HARDENED STEELS 0,77 0.0303 3,0 10,2 38,0 130 08302 08119 NON-FERROUS 0,78 0.0307 3,0 10,2 38,0 130 08303 08120 PLASTICS/COMPOSITES 0,79 0.0311 3,0 10,2 38,0 130 08304 08121 0,80 0.0315 3,0 10,2 38,0 130 08305 08122 0,80 0.0315 3,0 11,0 50,0 130 08306 08123 0,81 0.0319 3,0 10,2 38,0 130 08307 08124 0,82 0.0323 3,0 10,2 38,0 130 08308 08125 0,83 0.0327 3,0 10,2 38,0 130 08309 08126 0,84 0.0331 3,0 10,2 38,0 130 08310 08127 0,85 0.0335 3,0 10,2 38,0 130 08311 08128 0,85 0.0335 3,0 13,0 50,0 130 08312 08129 0,86 0.0339 3,0 10,2 38,0 130 08313 08130 0,87 0.0343 3,0 10,2 38,0 130 08314 08131 0,88 0.0346 3,0 10,2 38,0 130 08315 08132 0,89 0.0350 3,0 10,2 38,0 130 08316 08133 0,90 0.0354 3,0 10,2 38,0 130 08317 08134 0,90 0.0354 3,0 13,0 50,0 130 08318 08135 0,91 0.0358 3,0 10,2 38,0 130 08319 08136 0,92 0.0362 3,0 10,2 38,0 130 08320 08137 0,93 0.0366 3,0 10,2 38,0 130 08321 08138 0,94 0.0370 3,0 10,2 38,0 130 08322 08139 0,95 0.0374 3,0 10,2 38,0 130 08323 08140 0,95 0.0374 3,0 15,0 50,0 130 08324 08141 0,96 0.0378 3,0 10,2 38,0 130 08325 08142 0,97 0.0382 3,0 10,2 38,0 130 08326 08143 0,98 0.0386 3,0 10,2 38,0 130 08327 08144 0,99 0.0390 3,0 10,2 38,0 130 08328 08145 1,00 0.0394 3,0 10,2 38,0 130 08329 08146 continued on next page www.sgsmicrDoRtoILoLlSs.com DRILLS 129

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2018

Общий каталог SGS 2018 Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33