Каталог SGS микро инструмент 2021 - страница 119

Навигация

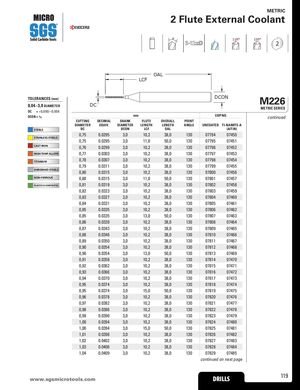

METRIC 2 Flute External Coolant 118° 130° 2 OAL LCF TOLERANCES (mm)0,04–3,0 DIAMETER DC DCON M226 METRIC SERIES DC = +0,000/–0,008 DCON = h6 mm EDP NO. continued CUTTING DECIMAL SHANK FLUTE OVERALL POINT DIAMETER EQUIV. DIAMETER LENGTH LENGTH ANGLE UNCOATED TI-NAMITE-A STEELS DC DCON LCF OAL (AlTiN) 0,75 0.0295 3,0 10,2 38,0 130 07794 07450 STAINLESS STEELS 0,75 0.0295 3,0 11,0 50,0 130 07795 07451 CAST IRON 0,76 0.0299 3,0 10,2 38,0 130 07796 07452 HIGH TEMP ALLOYS 0,77 0.0303 3,0 10,2 38,0 130 07797 07453 TITANIUM 0,78 0.0307 3,0 10,2 38,0 130 07798 07454 0,79 0.0311 3,0 10,2 38,0 130 07799 07455 HARDENED STEELS 0,80 0.0315 3,0 10,2 38,0 130 07800 07456 NON-FERROUS 0,80 0.0315 3,0 11,0 50,0 130 07801 07457 PLASTICS/COMPOSITES 0,81 0.0319 3,0 10,2 38,0 130 07802 07458 0,82 0.0323 3,0 10,2 38,0 130 07803 07459 0,83 0.0327 3,0 10,2 38,0 130 07804 07460 0,84 0.0331 3,0 10,2 38,0 130 07805 07461 0,85 0.0335 3,0 10,2 38,0 130 07806 07462 0,85 0.0335 3,0 13,0 50,0 130 07807 07463 0,86 0.0339 3,0 10,2 38,0 130 07808 07464 0,87 0.0343 3,0 10,2 38,0 130 07809 07465 0,88 0.0346 3,0 10,2 38,0 130 07810 07466 0,89 0.0350 3,0 10,2 38,0 130 07811 07467 0,90 0.0354 3,0 10,2 38,0 130 07812 07468 0,90 0.0354 3,0 13,0 50,0 130 07813 07469 0,91 0.0358 3,0 10,2 38,0 130 07814 07470 0,92 0.0362 3,0 10,2 38,0 130 07815 07471 0,93 0.0366 3,0 10,2 38,0 130 07816 07472 0,94 0.0370 3,0 10,2 38,0 130 07817 07473 0,95 0.0374 3,0 10,2 38,0 130 07818 07474 0,95 0.0374 3,0 15,0 50,0 130 07819 07475 0,96 0.0378 3,0 10,2 38,0 130 07820 07476 0,97 0.0382 3,0 10,2 38,0 130 07821 07477 0,98 0.0386 3,0 10,2 38,0 130 07822 07478 0,99 0.0390 3,0 10,2 38,0 130 07823 07479 1,00 0.0394 3,0 10,2 38,0 130 07824 07480 1,00 0.0394 3,0 15,0 50,0 130 07825 07481 1,01 0.0398 3,0 10,2 38,0 130 07826 07482 1,02 0.0402 3,0 10,2 38,0 130 07827 07483 1,03 0.0406 3,0 10,2 38,0 130 07828 07484 1,04 0.0409 3,0 10,2 38,0 130 07829 07485 continued on next page www.sgsmicrDoRtoILoLlSs.com DRILLS 119

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2018

Общий каталог SGS 2018 Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33