Каталог SGS монолитный инструмент из композитных материалов - страница 2

Навигация

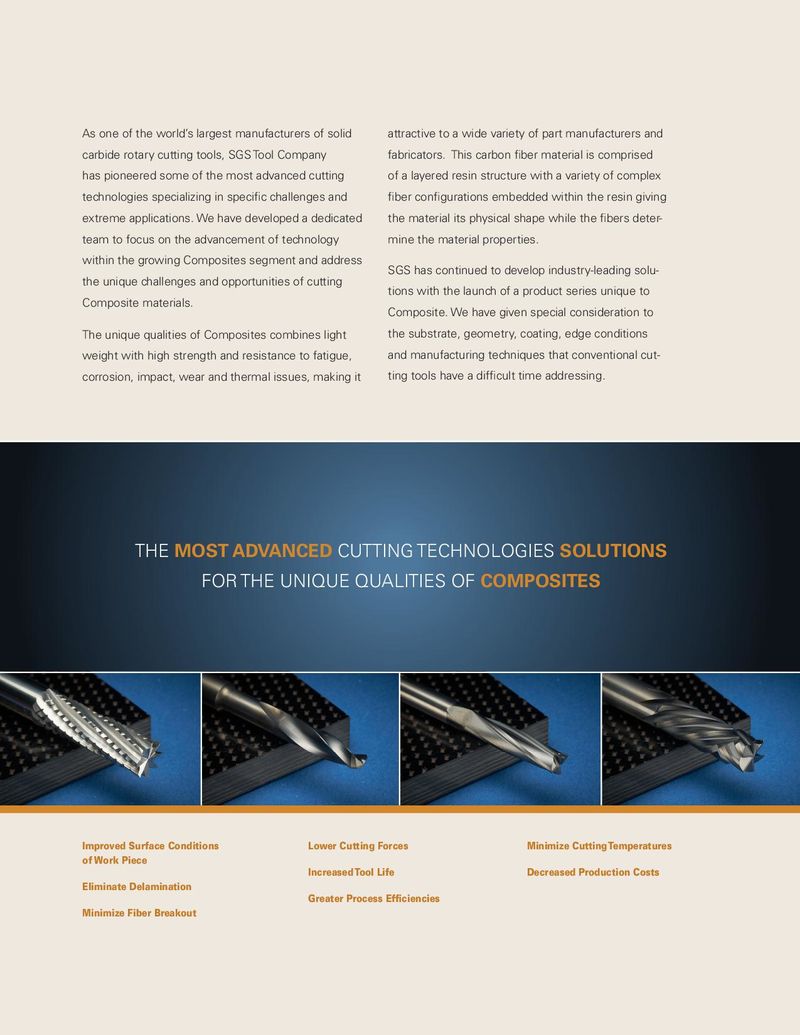

As one of the world’s largest manufacturers of solid attractive to a wide variety of part manufacturers and carbide rotary cutting tools, SGS Tool Company fabricators. This carbon fiber material is comprised has pioneered some of the most advanced cutting of a layered resin structure with a variety of complex technologies specializing in specific challenges and fiber configurations embedded within the resin giving extreme applications. We have developed a dedicated the material its physical shape while the fibers deter- team to focus on the advancement of technology mine the material properties. within the growing Composites segment and address SGS has continued to develop industry-leading solu- the unique challenges and opportunities of cutting tions with the launch of a product series unique to Composite materials. Composite. We have given special consideration to The unique qualities of Composites combines light the substrate, geometry, coating, edge conditions weight with high strength and resistance to fatigue, and manufacturing techniques that conventional cut- corrosion, impact, wear and thermal issues, making it ting tools have a difficult time addressing. THE MOST ADVANCED CUTTING TECHNOLOGIES SOLUTIONS FOR THE UNIQUE QUALITIES OF COMPOSITES Improved Surface Conditions Lower Cutting Forces Minimize Cutting Temperatures of Work Piece Increased Tool Life Decreased Production Costs Eliminate Delamination Greater Process Efficiencies Minimize Fiber Breakout

Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS микроинструмент

Каталог SGS микроинструмент Общий каталог SGS 2021

Общий каталог SGS 2021 Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series