Общий каталог PRECITOOL - страница 474

Навигация

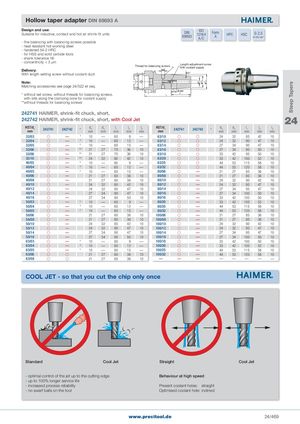

d1 d 3 d4 Steep Tapers Hollow taper adapter DIN 69893 A Design and use:Suitable for inductive, contact and hot air shrink-fit units DIN69893ISO12164A/C FormA HPC HSC G 2,5 25.000 min-1 - fine balancing with balancing screws possible - heat resistant hot-working steel - hardened 54-2 HRC - for HSS and solid carbide tools - shank tolerance h6 - concentricity < 3 µm Thread for balancing screws Length adjustment screwwith coolant supply Delivery: With length setting screw without coolant duct Note: Matching accessories see page 24/522 et seq. l3 * without set screw, without threads for balancing screws, l1 l2 with slits along the clamping bore for coolant supply **without threads for balancing screws 242741 HAIMER, shrink-fit chuck, short, 242742 HAIMER, shrink-fit chuck, short, with Cool Jet 24 HST/d1mm 242741 242742 * d3mm d4mm l1mm l2mm l3mm HST/d1mm 242741 242742 * d3mm d4mm l1mm l2mm l3mm 32/03 — * 10 — 60 9 — 63/10 24 32 85 42 10 32/04 — * 10 — 60 12 — 63/12 24 32 90 47 10 32/05 — * 10 — 60 15 — 63/14 27 34 90 47 10 32/06 — ** 21 27 70 36 10 63/16 27 34 95 50 10 32/08 — ** 21 27 70 36 10 63/18 33 42 95 50 10 32/10 — ** 24 32 80 42 10 63/20 33 42 100 52 10 40/03 — * 10 — 60 9 — 63/25 44 53 115 58 10 40/04 — * 10 — 60 12 — 63/32 44 53 120 58 10 40/05 — * 10 — 60 15 — 80/06 — 21 27 85 36 10 40/06 — 21 27 80 36 10 80/08 — 21 27 85 36 10 40/08 — 21 27 80 36 10 80/10 — 24 32 90 42 10 40/10 — 24 32 80 42 10 80/12 — 24 32 95 47 10 40/12 — 24 32 90 47 10 80/14 — 27 34 95 47 10 40/14 — 27 34 90 47 10 80/16 — 27 34 100 50 10 40/16 — 27 34 90 50 10 80/18 — 33 42 100 50 10 50/03 — * 10 — 60 9 — 80/20 — 33 42 105 52 10 50/04 — * 10 — 60 12 — 80/25 — 44 53 115 58 10 50/05 — * 10 — 60 15 — 80/32 — 44 53 120 58 10 50/06 — 21 27 80 36 10 100/06 — 21 27 85 36 10 50/08 — 21 27 80 36 10 100/08 — 21 27 85 36 10 50/10 — 24 32 85 42 10 100/10 — 24 32 90 42 10 50/12 — 24 32 90 47 10 100/12 — 24 32 95 47 10 50/14 — 27 34 90 47 10 100/14 — 27 34 95 47 10 50/16 — 27 34 95 50 10 100/16 — 27 34 100 50 10 63/03 — * 10 — 80 9 — 100/18 — 33 42 100 50 10 63/04 — * 10 — 80 12 — 100/20 — 33 42 105 52 10 63/05 — * 10 — 80 15 — 100/25 — 44 53 115 58 10 63/06 21 27 80 36 10 100/32 — 44 53 120 58 10 63/08 21 27 80 36 10 — — — — — — — — COOL JET - so that you cut the chip only once Standard Cool Jet Straight Cool Jet - optimal control of the jet up to the cutting edge Behaviour at high speed - up to 100% longer service life - increased process reliability Present coolant holes: straight - no swarf balls on the tool Optimised coolant hole: inclined www.precitool.de 24/469