Общий каталог OSG 2018 - 2019 - страница 299

Навигация

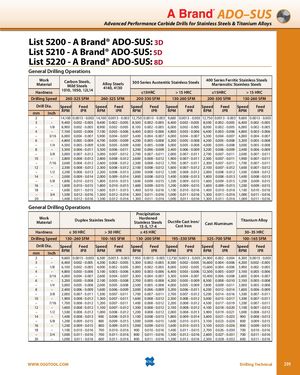

ADO–SUS Advanced Performance Carbide Drills for Stainless Steels & Titanium Alloys List 5200 - A Brand® ADO-SUS: 3D List 5210 - A Brand® ADO-SUS: 5D List 5220 - A Brand® ADO-SUS: 8D General Drilling Operations WorkMaterialHardnessCarbon Steels,Mild Steels1010, 1050, 12L14Alloy Steels4140, 4130300 Series Austenitic Stainless Steels400 Series Ferritic Stainless SteelsMartensitic Stainless Steels≤15HRC> 15 HRC≤15HRC> 15 HRC Drilling Speed 260-325 SFM 260-325 SFM 200-330 SFM 130-260 SFM 200-330 SFM 130-260 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 2 – 14,100 0.0013 - 0.003 14,100 0.0013 - 0.003 12,750 0.0013 - 0.003 9,600 0.0013 - 0.003 12,750 0.0013 - 0.003 9,600 0.0013 - 0.003 3 – 9,400 0.002 - 0.005 9,400 0.002 - 0.005 8,500 0.002 - 0.005 6,400 0.002 - 0.005 8,500 0.002 - 0.005 6,400 0.002 - 0.005 – 1/8 8,900 0.002 - 0.005 8,900 0.002 - 0.005 8,100 0.002 - 0.005 6,000 0.002 - 0.005 8,000 0.002 - 0.005 6,000 0.002 - 0.005 4 – 7,100 0.003 - 0.006 7,100 0.003 - 0.006 6,400 0.003 - 0.006 4,800 0.003 - 0.006 6,400 0.003 - 0.006 4,800 0.003 - 0.006 – 3/16 6,000 0.004 - 0.007 5,900 0.004 - 0.007 5,400 0.004 - 0.007 4,000 0.004 - 0.007 5,300 0.004 - 0.007 4,000 0.004 - 0.007 6 – 4,800 0.005 - 0.009 4,700 0.005 - 0.009 4,200 0.005 - 0.008 3,200 0.005 - 0.008 4,200 0.005 - 0.008 3,200 0.005 - 0.008 – 1/4 4,500 0.005 - 0.009 4,500 0.005 - 0.009 4,000 0.005 - 0.008 3,000 0.005 - 0.008 4,000 0.005 - 0.008 3,000 0.005 - 0.008 8 – 3,500 0.006 - 0.011 3,500 0.006 - 0.011 3,200 0.006 - 0.009 2,400 0.006 - 0.009 3,200 0.006 - 0.009 2,400 0.006 - 0.009 – 3/8 3,000 0.007 - 0.012 3,000 0.007 - 0.012 2,700 0.007 - 0.011 2,000 0.007 - 0.011 2,700 0.007 - 0.011 2,000 0.007 - 0.011 10 – 2,800 0.008 - 0.012 2,800 0.008 - 0.012 2,600 0.008 - 0.012 1,900 0.007 - 0.011 2,500 0.007 - 0.011 1,900 0.007 - 0.011 – 7/16 2,600 0.008 - 0.012 2,600 0.008 - 0.012 2,300 0.008 - 0.012 1,700 0.007 - 0.011 2,300 0.007 - 0.011 1,700 0.007 - 0.011 12 – 2,300 0.008 - 0.012 2,300 0.008 - 0.012 2,100 0.008 - 0.012 1,600 0.007 - 0.012 2,100 0.007 - 0.012 1,600 0.007 - 0.012 – 1/2 2,200 0.008 - 0.013 2,200 0.008 - 0.013 2,000 0.008 - 0.012 1,500 0.008 - 0.012 2,000 0.008 - 0.012 1,500 0.008 - 0.012 14 – 2,000 0.009 - 0.014 2,000 0.009 - 0.014 1,800 0.008 - 0.013 1,400 0.008 - 0.013 1,800 0.008 - 0.013 1,400 0.008 - 0.013 – 5/8 1,800 0.010 - 0.015 1,800 0.010 - 0.015 1,600 0.009 - 0.015 1,200 0.009 - 0.015 1,600 0.009 - 0.015 1,200 0.009 - 0.015 16 – 1,800 0.010 - 0.015 1,800 0.010 - 0.015 1,600 0.009 - 0.015 1,200 0.009 - 0.015 1,600 0.009 - 0.015 1,200 0.009 - 0.015 18 – 1,600 0.011 - 0.015 1,600 0.011 - 0.015 1,400 0.010 - 0.016 1,100 0.010 - 0.016 1,400 0.010 - 0.016 1,100 0.010 - 0.016 – 3/4 1,500 0.012 - 0.016 1,500 0.012 - 0.016 1,300 0.011 - 0.016 1,000 0.011 - 0.016 1,300 0.011 - 0.016 1,000 0.011 - 0.016 20 – 1,400 0.012 - 0.016 1,500 0.012 - 0.016 1,300 0.011 - 0.016 1,000 0.011 - 0.016 1,300 0.011 - 0.016 1,000 0.011 - 0.016 General Drilling Operations Precipitation WorkMaterial Duplex Stainles Steels HardenedStainless Steels15-5, 17-4Ductile Cast Iron/Cast IronCast AluminumTitanium Alloy Hardness ≤ 30 HRC > 30 HRC ≤ 45 HRC 30–35 HRC Drilling Speed 130–260 SFM 100–165 SFM 130 -200 SFM 195–330 SFM 325–700 SFM 100–165 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 2 – 9,600 0.0013 - 0.003 6,300 0.0013 - 0.003 7,950 0.0013 - 0.003 12,750 0.0013 - 0.003 24,900 0.002 - 0.004 6,300 0.0013 - 0.003 3 – 6,400 0.002 - 0.005 4,200 0.002 - 0.005 5,300 0.002 - 0.005 8,500 0.002 - 0.005 16,600 0.004 - 0.006 4,200 0.002 - 0.005 – 1/8 6,100 0.002 - 0.005 4,000 0.002 - 0.005 5,000 0.002 - 0.005 8,000 0.002 - 0.005 15,600 0.004 - 0.006 3,900 0.002 - 0.005 4 – 4,800 0.003 - 0.006 3,100 0.003 - 0.006 4,000 0.003 - 0.006 6,400 0.003 - 0.006 12,500 0.005 - 0.007 3,100 0.003 - 0.006 – 3/16 4,000 0.004 - 0.007 2,600 0.004 - 0.007 3,300 0.004 - 0.007 5,300 0.004 - 0.007 10,400 0.006 - 0.008 2,600 0.004 - 0.007 6 – 3,200 0.005 - 0.008 2,100 0.005 - 0.008 2,700 0.005 - 0.008 4,200 0.005 - 0.009 8,300 0.008 - 0.010 2,100 0.005 - 0.008 – 1/4 3,000 0.005 - 0.008 2,000 0.005 - 0.008 2,500 0.005 - 0.008 4,000 0.005 - 0.009 7,800 0.009 - 0.011 2,000 0.005 - 0.008 8 – 2,400 0.006 - 0.009 1,600 0.006 - 0.009 2,000 0.006 - 0.009 3,200 0.006 - 0.011 6,200 0.012 - 0.014 1,600 0.006 - 0.009 – 3/8 2,000 0.007 - 0.011 1,300 0.007 - 0.011 1,700 0.007 - 0.011 2,700 0.007 - 0.012 5,200 0.014 - 0.016 1,300 0.007 - 0.011 10 – 1,900 0.008 - 0.012 1,300 0.007 - 0.011 1,600 0.008 - 0.012 2,500 0.008 - 0.012 5,000 0.015 - 0.017 1,300 0.007 - 0.011 – 7/16 1,700 0.008 - 0.012 1,200 0.007 - 0.011 1,400 0.008 - 0.012 2,200 0.008 - 0.012 4,500 0.017 - 0.019 1,200 0.007 - 0.011 12 – 1,600 0.008 - 0.012 1,100 0.007 - 0.012 1,300 0.008 - 0.012 2,100 0.008 - 0.012 4,100 0.018 - 0.020 1,100 0.007 - 0.012 – 1/2 1,500 0.008 - 0.012 1,000 0.008 - 0.012 1,200 0.008 - 0.012 2,000 0.008 - 0.013 3,900 0.019 - 0.021 1,000 0.008 - 0.012 14 – 1,400 0.008 - 0.013 900 0.008 - 0.013 1,100 0.008 - 0.013 1,800 0.009 - 0.014 3,600 0.021 - 0.023 900 0.008 - 0.013 – 5/8 1,200 0.009 - 0.015 800 0.009 - 0.015 1,000 0.009 - 0.015 1,600 0.010 - 0.015 3,100 0.023 - 0.026 800 0.009 - 0.015 16 – 1,200 0.009 - 0.015 800 0.009 - 0.015 1,000 0.009 - 0.015 1,600 0.010 - 0.015 3,100 0.023 - 0.026 800 0.009 - 0.015 18 – 1,100 0.010 - 0.016 700 0.010 - 0.016 900 0.010 - 0.016 1,400 0.011 - 0.015 2,700 0.026 - 0.030 700 0.010 - 0.016 – 3/4 1,000 0.011 - 0.016 700 0.011 - 0.016 800 0.011 - 0.016 1,300 0.012 - 0.016 2,600 0.027 - 0.031 700 0.011 - 0.016 20 – 1,000 0.011 - 0.016 600 0.011 - 0.016 800 0.011 - 0.016 1,300 0.012 - 0.016 2,500 0.028 - 0.032 600 0.011 - 0.016 WWW.OSGTOOL.COM Drilling Technical 299

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta