Общий каталог OSG 2018 - 2019 - страница 298

Навигация

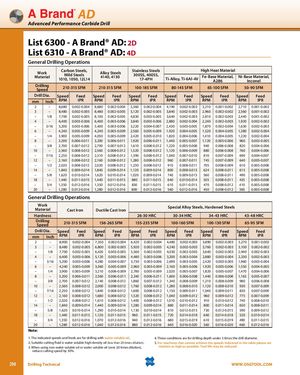

AD Advanced Performance Carbide Drill List 6300 - A Brand® AD: 2D List 6310 - A Brand® AD: 4D General Drilling Operations WorkMaterialCarbon Steels,Mild Steels1010, 1050, 12L14Alloy Steels4140, 4130Stainless Steels High Heat Material300SS, 400SS,17-4PHTi-Alloy, Ti-6Al-4VFe-Base Material,A286Ni-Base Material,Inconel DrillingSpeed 210-315 SFM 210-315 SFM 100-185 SFM 80-145 SFM 65-100 SFM 50-90 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 2 – 8,680 0.002-0.004 8,680 0.002-0.004 5,360 0.002-0.004 4,190 0.002-0.003 3,210 0.001-0.002 2,710 0.001-0.002 3 – 8,480 0.002-0.005 8,480 0.002-0.005 5,120 0.002-0.005 3,840 0.002-0.003 2,960 0.002-0.002 2,560 0.001-0.002 – 1/8 7,700 0.002-0.005 8,100 0.002-0.005 4,830 0.003-0.005 3,640 0.002-0.003 2,810 0.002-0.003 2,440 0.001-0.002 4 – 6,400 0.003-0.006 6,400 0.003-0.006 3,840 0.003-0.006 2,880 0.002-0.004 2,240 0.002-0.003 1,920 0.002-0.002 – 3/16 5,200 0.003-0.006 5,400 0.003-0.006 3,220 0.004-0.007 2,430 0.003-0.005 1,870 0.002-0.004 1,630 0.002-0.003 6 – 4,240 0.005-0.009 4,240 0.005-0.009 2,560 0.005-0.009 1,920 0.004-0.005 1,520 0.004-0.005 1,280 0.002-0.004 – 1/4 3,900 0.005-0.009 4,050 0.005-0.009 2,420 0.005-0.010 1,820 0.004-0.006 1,410 0.004-0.005 1,220 0.002-0.004 8 – 3,200 0.006-0.011 3,200 0.006-0.011 1,920 0.006-0.011 1,440 0.005-0.007 1,120 0.005-0.006 960 0.003-0.005 – 3/8 2,700 0.007-0.012 2,700 0.007-0.012 1,610 0.008-0.012 1,220 0.005-0.008 940 0.006-0.008 820 0.004-0.006 10 – 2,560 0.008-0.012 2,560 0.008-0.012 1,520 0.008-0.012 1,120 0.006-0.009 880 0.006-0.008 760 0.004-0.006 – 7/16 2,250 0.008-0.012 2,310 0.008-0.012 1,390 0.008-0.012 1,040 0.007-0.010 810 0.007-0.009 690 0.004-0.007 12 – 2,160 0.008-0.012 2,160 0.008-0.012 1,280 0.008-0.012 960 0.007-0.011 745 0.007-0.009 640 0.005-0.007 – 1/2 2,020 0.008-0.012 2,020 0.008-0.012 1,230 0.008-0.012 910 0.008-0.011 705 0.008-0.009 610 0.005-0.008 14 – 1,840 0.009-0.014 1,840 0.009-0.014 1,120 0.009-0.014 800 0.008-0.013 624 0.008-0.011 615 0.005-0.008 – 5/8 1,620 0.010-0.014 1,620 0.010-0.014 1,020 0.009-0.014 740 0.009-0.013 560 0.008-0.011 490 0.005-0.008 18 – 1,440 0.011-0.015 1,440 0.011-0.015 880 0.011-0.015 640 0.010-0.014 505 0.008-0.011 435 0.005-0.008 – 3/4 1,350 0.012-0.016 1,350 0.012-0.016 830 0.011-0.015 610 0.011-0.015 470 0.008-0.012 410 0.005-0.008 20 – 1,280 0.012-0.016 1,280 0.012-0.016 800 0.012-0.016 560 0.012-0.016 450 0.008-0.012 385 0.005-0.008 General Drilling Operations WorkMaterial Cast Iron Ductile Cast Iron Special Alloy Steels, Hardened Steels Hardness 26-30 HRC 30-34 HRC 34-43 HRC 43-48 HRC DrillingSpeed 210-315 SFM 156-265 SFM 155-235 SFM 100-160 SFM 100-130 SFM 65-95 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 2 – 8,900 0.002-0.004 7,350 0.002-0.004 6,420 0.002-0.004 4,480 0.002-0.003 3,890 0.002-0.003 3,270 0.001-0.002 3 – 8,480 0.002-0.005 6,800 0.002-0.005 5,920 0.002-0.005 4,240 0.002-0.003 3,760 0.002-0.003 3,100 0.002-0.002 – 1/8 7,700 0.002-0.005 6,420 0.003-0.005 5,560 0.002-0.005 4,030 0.002-0.003 3,640 0.002-0.003 2,940 0.002-0.003 4 – 6,400 0.003-0.006 5,120 0.003-0.006 4,480 0.003-0.006 3,200 0.003-0.004 2,880 0.003-0.004 2,330 0.002-0.003 – 3/16 5,200 0.003-0.006 4,280 0.004-0.007 3,730 0.003-0.006 2,690 0.003-0.005 2,420 0.003-0.005 1,960 0.003-0.004 6 – 4,240 0.005-0.009 3,360 0.005-0.009 2,960 0.005-0.009 2,160 0.005-0.006 1,920 0.005-0.006 1,550 0.004-0.005 – 1/4 3,900 0.005-0.009 3,210 0.006-0.009 2,780 0.005-0.009 2,020 0.005-0.007 1,820 0.005-0.007 1,470 0.004-0.006 8 – 3,200 0.006-0.011 2,560 0.006-0.011 2,240 0.006-0.011 1,600 0.006-0.008 1,440 0.006-0.008 1,165 0.005-0.007 – 3/8 2,700 0.007-0.012 2,140 0.008-0.012 1,860 0.007-0.012 1,340 0.008-0.009 1,210 0.008-0.009 980 0.006-0.008 10 – 2,560 0.008-0.012 2,000 0.008-0.012 1,760 0.008-0.012 1,280 0.008-0.010 1,120 0.008-0.010 930 0.007-0.009 – 7/16 2,250 0.008-0.012 1,840 0.008-0.012 1,600 0.008-0.012 1,150 0.009-0.011 1,040 0.009-0.011 830 0.007-0.009 12 – 2,160 0.008-0.012 1,680 0.008-0.012 1,520 0.008-0.012 1,040 0.009-0.012 960 0.009-0.012 775 0.007-0.009 – 1/2 2,020 0.008-0.012 1,610 0.008-0.012 1,400 0.008-0.012 1,010 0.010-0.012 910 0.010-0.012 740 0.008-0.010 14 – 1,840 0.009-0.014 1,440 0.009-0.014 1,280 0.009-0.014 880 0.011-0.014 800 0.011-0.014 650 0.008-0.011 – 5/8 1,620 0.010-0.014 1,290 0.010-0.014 1,130 0.010-0.014 810 0.012-0.015 730 0.012-0.015 590 0.009-0.012 18 – 1,440 0.011-0.015 1,120 0.011-0.015 960 0.011-0.015 720 0.014-0.018 640 0.014-0.018 520 0.010-0.014 – 3/4 1,350 0.012-0.016 1,070 0.012-0.016 940 0.012-0.016 680 0.015-0.019 610 0.015-0.019 490 0.011-0.015 20 – 1,280 0.012-0.016 1,040 0.012-0.016 880 0.012-0.016 640 0.016-0.020 560 0.016-0.020 460 0.012-0.016 Note: 1. The indicated speeds and feeds are for drilling with water-soluble oil. 4. These conditions are for drilling depth under 3 times the drill diameter. 2. Suitable cutting fluid is water-soluble high density oil (less than 20 times dilution). 5. For machines that cannot achieve the speeds indicated in the table please set 3. When using non-water-soluble oil or water-soluble oil (over 20 times dilution), rotation as high as possible. Tool life may be reduced. reduce cutting speed by 30%. 298 Drilling Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta