Общий каталог OSG 2018 - 2019 - страница 1036

Навигация

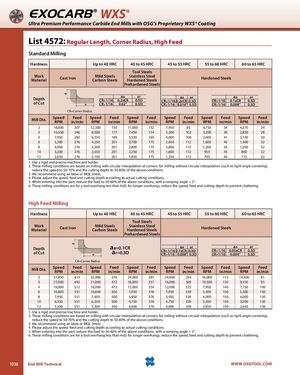

EXOCARB® WXS® Ultra Premium Performance Carbide End Mills with OSG’s Proprietary WXS® Coating List 4572: Regular Length, Corner Radius, High Feed Standard Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC Tool Steels WorkMaterial Cast Iron Mild Steels Stainless SteelCarbon SteelsHardened Steels Hardened Steels Prehardened Steels Depthof Cut aa ar aa ar aa arCR≤1/160.2xCR0.5D CR≤1/16 0.2xCR0.5DCR≤1/160.1xCR0.5D CR>1/160.02”0.5DCR>1/160.016”0.5DCR>1/160.008”0.5D CR=Corner Radius Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min 2 16,000 207 12,500 150 11,000 132 7,950 85 4,750 34 4,270 24 3 10,500 246 8,500 177 7,450 154 5,300 102 3,200 39 2,850 28 4 7,950 260 6,350 189 5,550 165 4,000 108 2,400 41 2,150 30 6 5,300 276 4,250 201 3,700 175 2,650 112 1,600 45 1,400 32 8 4,000 276 3,200 201 2,800 175 2,000 112 1,200 45 1,050 32 10 3,200 276 2,550 201 2,250 175 1,600 112 955 45 860 32 12 2,650 276 2,100 201 1,850 175 1,350 112 795 45 715 32 1. Use a rigid and precise machine and holder. 2. These milling conditions are based on milling with circular interpolation at corners; for milling without circular interpolation (such as right angle cornering), reduce the speed to 50-70% and the cutting depth to 50-80% of the above conditions. 3. We recommend using air blow or MQL (mist). 4. Please adjust the speed, feed and cutting depth according to actual cutting conditions. 5. When entering into the part, reduce the feed to 30-60% of the above conditions, with a ramping angle < 2°. 6. These milling conditions are for a tool overhang less than 4xD; for longer overhangs, reduce the speed, feed and cutting depth to prevent chattering. High Feed Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC Tool Steels WorkMaterial Cast Iron Mild Steels Stainless SteelCarbon SteelsHardened Steels Hardened Steels Prehardened Steels Depthof Cut aa=0.1CRar=0.3D aa ar aa arCR≤1/16 0.1xCR0.3DCR≤1/160.05xCR0.3D CR>1/160.008”0.3DCR>1/160.004”0.3D CR=Corner Radius Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min 2 31,850 413 32,000 376 24,000 281 24,000 254 16,000 112 14,400 81 3 21,000 492 21,000 472 16,000 331 16,000 309 10,500 130 9,450 93 4 16,000 512 16,000 472 12,000 354 12,000 323 7,950 140 7,150 100 6 10,600 551 10,600 500 7,950 376 7,950 339 5,300 150 5,300 150 8 7,950 551 7,950 500 5,950 376 5,950 339 4,000 150 4,000 150 10 6,350 551 6,350 500 4,750 376 4,750 339 3,200 150 3,200 150 12 5,300 551 5,300 500 4,000 376 4,000 339 2,650 150 2,650 150 1. Use a rigid and precise machine and holder. 2. These milling conditions are based on milling with circular interpolation at corners; for milling without circular interpolation (such as right angle cornering), reduce the speed to 50-70% and the cutting depth to 50-80% of the above conditions. 3. We recommend using air blow or MQL (mist). 4. Please adjust the speed, feed and cutting depth according to actual cutting conditions. 5. When entering into the part, reduce the feed to 30-60% of the above conditions, with a ramping angle < 2°. 6. These milling conditions are for a tool overhang less than 4xD; for longer overhangs, reduce the speed, feed and cutting depth to prevent chattering. 1036 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta