Общий каталог OSG 2018 - 2019 - страница 1035

Навигация

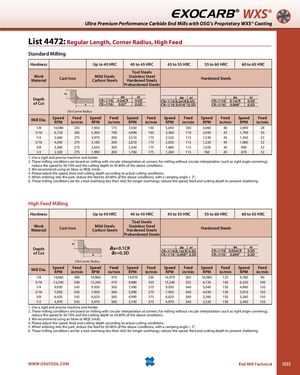

EXOCARB® WXS® Ultra Premium Performance Carbide End Mills with OSG’s Proprietary WXS® Coating List 4472: Regular Length, Corner Radius, High Feed Standard Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC Tool Steels WorkMaterial Cast Iron Mild Steels Stainless SteelCarbon SteelsHardened Steels Hardened Steels Prehardened Steels Depthof Cut aa ar aa ar aa arCR≤1/160.2xCR0.5D CR≤1/16 0.2xCR 0.5DCR≤1/160.1xCR0.5D CR>1/160.02”0.5DCR>1/160.016”0.5DCR>1/160.008”0.5D CR=Corner Radius Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeed RPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min 1/8 10,080 255 7,950 175 7,030 150 5,040 100 3,060 40 2,690 28 3/16 6,720 265 5,300 190 4,690 165 3,360 110 2,040 42 1,790 30 1/4 5,040 275 3,970 200 3,510 175 2,520 115 1,530 45 1,340 32 5/16 4,030 275 3,180 200 2,810 175 2,020 115 1,220 45 1,080 32 3/8 3,360 275 2,650 200 2,340 175 1,680 115 1,020 45 900 32 1/2 2,520 275 1,990 200 1,760 175 1,260 115 760 45 670 32 1. Use a rigid and precise machine and holder. 2. These milling conditions are based on milling with circular interpolation at corners; for milling without circular interpolation (such as right angle cornering), reduce the speed to 50-70% and the cutting depth to 50-80% of the above conditions. 3. We recommend using air blow or MQL (mist). 4. Please adjust the speed, feed and cutting depth according to actual cutting conditions. 5. When entering into the part, reduce the feed to 30-60% of the above conditions, with a ramping angle < 2°. 6. These milling conditions are for a tool overhang less than 4xD; for longer overhangs, reduce the speed, feed and cutting depth to prevent chattering. High Feed Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC Tool Steels WorkMaterial Cast Iron Mild Steels Stainless SteelCarbon SteelsHardened Steels Hardened Steels Prehardened Steels Depthof Cut aa=0.1CRar=0.3D aa ar aa arCR≤1/16 0.1xCR0.3DCR≤1/160.05xCR0.3D CR>1/160.008”0.3DCR>1/160.004”0.3D CR=Corner Radius Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeed RPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min 1/8 19,860 490 19,860 470 14,970 330 14,970 305 10,080 125 9,780 90 3/16 13,240 500 13,240 470 9,980 355 13,240 325 6,720 140 6,520 100 1/4 9,930 545 9,930 500 7,490 375 9,930 340 5,040 150 4,890 150 5/16 7,950 545 7,950 500 5,990 375 7,950 340 4,030 150 3,910 150 3/8 6,620 545 6,620 500 4,990 375 6,620 340 3,360 150 3,260 150 1/2 4,970 545 4,970 500 3,740 375 4,970 340 2,520 150 2,440 150 1. Use a rigid and precise machine and holder. 2. These milling conditions are based on milling with circular interpolation at corners; for milling without circular interpolation (such as right angle cornering), reduce the speed to 50-70% and the cutting depth to 50-80% of the above conditions. 3. We recommend using air blow or MQL (mist). 4. Please adjust the speed, feed and cutting depth according to actual cutting conditions. 5. When entering into the part, reduce the feed to 30-60% of the above conditions, with a ramping angle < 2°. 6. These milling conditions are for a tool overhang less than 4xD; for longer overhangs, reduce the speed, feed and cutting depth to prevent chattering. WWW.OSGTOOL.COM End Mill Technical 1035

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta