Общий каталог OSG 2018 - 2019 - страница 1034

Навигация

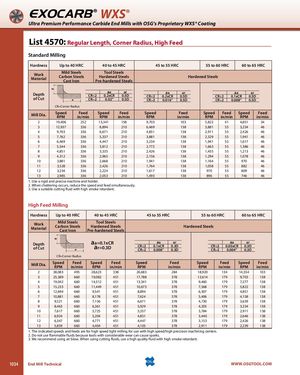

EXOCARB® WXS® Ultra Premium Performance Carbide End Mills with OSG’s Proprietary WXS® Coating List 4570: Regular Length, Corner Radius, High Feed Standard Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC WorkMaterial Mild Steels Tool SteelsCarbon SteelsHardened SteelsCast IronPre-hardened SteelsHardened Steels Depthof Cut aa ar aa ar aa arCR≤20.2xCR0.5D CR≤20.2xCR0.5D CR≤20.1xCR0.5D CR>20.02”0.5DCR>20.016”0.5DCR>20.008”0.5D CR=Corner Radius Mill Dia. SpeedRPM Feed Speed Feedin/minRPMin/minSpeedRPM Feed Speed Feed Speed Feedin/minRPMin/minRPMin/min 2 19,406 252 13,341 158 9,703 103 5,822 41 4,851 34 3 12,937 336 8,894 210 6,469 138 3,881 55 3,234 46 4 9,703 336 6,671 210 4,851 138 2,911 55 2,426 46 5 7,762 336 5,337 210 3,881 138 2,329 55 1,941 46 6 6,469 336 4,447 210 3,234 138 1,941 55 1,617 46 7 5,544 336 3,812 210 2,772 138 1,663 55 1,386 46 8 4,851 336 3,335 210 2,426 138 1,455 55 1,213 46 9 4,312 336 2,965 210 2,156 138 1,294 55 1,078 46 10 3,881 336 2,668 210 1,941 138 1,164 55 970 46 11 3,528 336 2,426 210 1,764 138 1,058 55 882 46 12 3,234 336 2,224 210 1,617 138 970 55 809 46 13 2,985 336 2,053 210 1,493 138 896 55 746 46 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. High Feed Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC WorkMaterial Mild Steels Tool SteelsCarbon SteelsHardened SteelsCast IronPre-hardened SteelsHardened Steels Depthof Cut aa=0.1xCR aa ar aa arar=0.3DCR≤20.1xCR0.3D CR>20.008”0.3DCR≤20.05xCR0.3D CR>20.004”0.3D CR=Corner Radius Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feed Speed Feed Speed Feedin/minRPMin/minRPMin/min 2 38,083 495 28,623 338 26,683 284 18,920 134 14,554 103 3 25,389 660 19,082 451 17,788 378 12,614 179 9,703 138 4 19,042 660 14,312 451 13,341 378 9,460 179 7,277 138 5 15,233 660 11,449 451 10,673 378 7,568 179 5,822 138 6 12,694 660 9,541 451 8,894 378 6,307 179 4,851 138 7 10,881 660 8,178 451 7,624 378 5,406 179 4,158 138 8 9,521 660 7,156 451 6,671 378 4,730 179 3,639 138 9 8,463 660 6,361 451 5,929 378 4,205 179 3,234 138 10 7,617 660 5,725 451 5,337 378 3,784 179 2,911 138 11 6,924 660 5,204 451 4,851 378 3,440 179 2,646 138 12 6,347 660 4,771 451 4,447 378 3,153 179 2,426 138 13 5,859 660 4,404 451 4,105 378 2,911 179 2,239 138 1. The indicated speeds and feeds are for high speed light milling for use with high speed/high precision machining centers. 2. Do not use flammable fluids because tools with considerable wear can cause sparks. 3. We recommend using air blow. When using cutting fluids, use a high quality fluid with high smoke retardant. 1034 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta