Общий каталог OSG 2018 - 2019 - страница 1033

Навигация

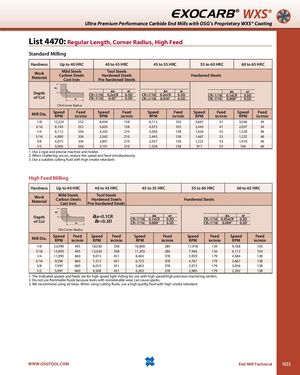

EXOCARB® WXS® Ultra Premium Performance Carbide End Mills with OSG’s Proprietary WXS® Coating List 4470: Regular Length, Corner Radius, High Feed Standard Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronTool SteelsHardened SteelsPre-hardened Steels Hardened Steels Depthof Cut aa ar aa ar aa arCR≤1/160.2xCR0.5D CR≤1/160.2xCR0.5D CR≤1/160.1xCR0.5D CR>1/160.02”0.5DCR>1/160.016”0.5DCR>1/160.008”0.5D CR=Corner Radius Mill Dia. SpeedRPM Feedin/min Speed RPM Feedin/min Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/min 1/8 12,224 252 8,404 158 6,112 103 3,667 41 3,056 34 3/16 8,149 252 5,603 158 4,075 103 2,445 41 2,037 34 1/4 6,112 336 4,202 210 3,056 138 1,834 55 1,528 46 5/16 4,890 336 3,362 210 2,445 138 1,467 55 1,222 46 3/8 4,075 336 2,801 210 2,037 138 1,222 55 1,019 46 1/2 3,056 336 2,101 210 1,528 138 917 55 764 46 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. High Feed Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC WorkMaterial Mild Steels Tool SteelsCarbon SteelsHardened SteelsCast IronPre-hardened SteelsHardened Steels Depthof Cut aa=0.1CRar=0.3D aa arCR≤1/160.1xCR0.3D CR>1/160.008”0.3D aa arCR≤1/160.05xCR0.3D CR>1/160.004”0.3D CR=Corner Radius Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feed Speed Feed Speed Feedin/minRPMin/minRPMin/min 1/8 23,990 495 18,030 338 16,808 284 11,918 134 9,168 103 3/16 15,993 495 12,020 338 11,205 284 7,946 134 6,112 103 1/4 11,995 660 9,015 451 8,404 378 5,959 179 4,584 138 5/16 9,596 660 7,212 451 6,723 378 4,767 179 3,667 138 3/8 7,997 660 6,010 451 5,603 378 3,973 179 3,056 138 1/2 5,997 660 4,508 451 4,202 378 2,980 179 2,292 138 1. The indicated speeds and feeds are for high speed light milling for use with high speed/high precision machining centers. 2. Do not use flammable fluids because tools with considerable wear can cause sparks. 3. We recommend using air blow. When using cutting fluids, use a high quality fluid with high smoke retardant. WWW.OSGTOOL.COM End Mill Technical 1033

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta