Общий каталог OSG 2018 - 2019 - страница 1032

Навигация

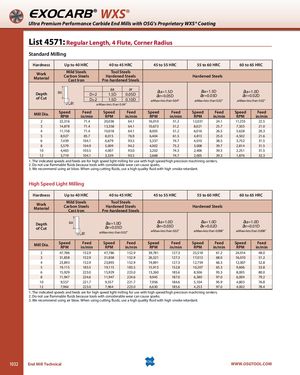

EXOCARB® WXS® Ultra Premium Performance Carbide End Mills with OSG’s Proprietary WXS® Coating List 4571: Regular Length, 4 Flute, Corner Radius Standard Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC WorkMaterial Mild Steels Tool SteelsCarbon SteelsHardened SteelsCast IronPre-hardened SteelsHardened Steels Depthof Cut aa ar aa=1.5DD=21.5D0.05Dar=0.05D aa=1.5D aa=1.0Dar=0.03Dar=0.02DD>21.5D0.10DarMax=less than 0.04”arMax=less than 0.02”arMax=less than 0.02” arMax=less than 0.04” Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min Speed Feed Speed FeedRPMin/minRPMin/min 2 22,316 71.4 20,036 64.1 16,010 51.2 12,031 24.1 11,255 22.5 3 14,878 71.4 13,358 64.1 10,673 51.2 8,021 25.7 7,503 21.0 4 11,158 71.4 10,018 64.1 8,005 51.2 6,016 26.5 5,628 20.3 5 8,927 85.7 8,015 76.9 6,404 61.5 4,813 25.0 4,502 21.6 6 7,439 104.1 6,679 93.5 5,337 74.7 4,010 38.5 3,752 31.5 8 5,579 104.9 5,009 94.2 4,002 75.2 3,008 39.7 2,814 31.5 10 4,463 103.5 4,007 93.0 3,202 74.3 2,406 39.5 2,251 31.5 12 3,719 104.1 3,339 93.5 2,668 74.7 2,005 39.3 1,876 32.3 1. The indicated speeds and feeds are for high speed light milling for use with high speed/high precision machining centers. 2. Do not use flammable fluids because tools with considerable wear can cause sparks. 3. We recommend using air blow. When using cutting fluids, use a high quality fluid with high smoke retardant. High Speed Light Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC WorkMaterial Mild Steels Tool SteelsCarbon SteelsHardened SteelsCast IronPre-hardened SteelsHardened Steels Depthof Cut aa=1.0Dar=0.05D aa=1.0D aa=1.0D aa=1.0Dar=0.03Dar=0.02Dar=0.01D arMax=less than 0.02” arMax=less than 0.02” arMax=less than 0.008” arMax=less than 0.008” Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min Speed Feed Speed FeedRPMin/minRPMin/min 2 47,786 152.9 47,786 152.9 39,781 127.3 25,518 61.2 24,014 48.0 3 31,858 152.9 31,858 152.9 26,521 127.3 17,012 68.0 16,010 51.2 4 23,893 152.9 23,893 152.9 19,891 127.3 12,759 66.3 12,007 52.8 5 19,115 183.5 19,115 183.5 15,913 152.8 10,207 65.3 9,606 53.8 6 15,929 223.0 15,929 223.0 13,260 185.6 8,506 95.3 8,005 80.0 8 11,947 224.6 11,947 224.6 9,945 187.0 6,380 97.0 6,004 79.2 10 9,557 221.7 9,557 221.7 7,956 184.6 5,104 95.9 4,803 76.8 12 7,964 223.0 7,964 223.0 6,630 185.6 4,253 97.0 4,002 78.4 1. The indicated speeds and feeds are for high speed light milling for use with high speed/high precision machining centers. 2. Do not use flammable fluids because tools with considerable wear can cause sparks. 3. We recommend using air blow. When using cutting fluids, use a high quality fluid with high smoke retardant. 1032 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta