Общий каталог OSG 2018 - 2019 - страница 1031

Навигация

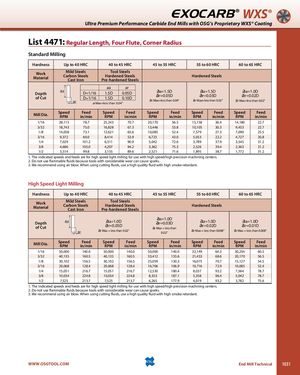

EXOCARB® WXS® Ultra Premium Performance Carbide End Mills with OSG’s Proprietary WXS® Coating List 4471: Regular Length, Four Flute, Corner Radius Standard Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC WorkMaterial Mild Steels Tool SteelsCarbon SteelsHardened SteelsCast IronPre-hardened SteelsHardened Steels Depthof Cut aa arD=1/161.5D0.05DD>1/161.5D0.10Daa=1.5Dar=0.05D aa=1.5Dar=0.03D aa=1.0Dar=0.02Dar Max=less than 0.04”ar Max=less than 0.02”ar Max=less than 0.02” arMax=less than 0.04” Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min Speed Feed Speed FeedRPMin/minRPMin/min 1/16 28,115 78.7 25,243 70.7 20,170 56.5 15,158 36.4 14,180 22.7 3/32 18,743 75.0 16,828 67.3 13,446 53.8 10,105 30.3 9,453 22.7 1/8 14,058 73.1 12,621 65.6 10,085 52.4 7,579 27.3 7,090 25.5 3/16 9,372 60.0 8,414 53.9 6,723 43.0 5,053 22.2 4,727 20.8 1/4 7,029 101.2 6,311 90.9 5,042 72.6 3,789 37.9 3,545 31.2 3/8 4,686 105.0 4,207 94.2 3,362 75.3 2,526 39.4 2,363 31.2 1/2 3,514 99.8 3,155 89.6 2,521 71.6 1,895 38.7 1,772 31.2 1. The indicated speeds and feeds are for high speed light milling for use with high speed/high precision machining centers. 2. Do not use flammable fluids because tools with considerable wear can cause sparks. 3. We recommend using air blow. When using cutting fluids, use a high quality fluid with high smoke retardant. High Speed Light Milling Hardness Up to 40 HRC 40 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC WorkMaterial Mild Steels Tool SteelsCarbon SteelsHardened SteelsCast IronPre-hardened SteelsHardened Steels Depthof Cut aa=1.0Dar=0.05Dar Max = less than 0.02”aa=1.0Dar=0.03Dar Max = less than0.02”aa=1.0D aa=1.0Dar=0.02Dar=0.01Dar Max = less than 0.008”ar Max = less than 0.008” Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min Speed Feed Speed FeedRPMin/minRPMin/min 1/16 50,000 140.0 50,000 140.0 50,000 140.0 32,149 64.3 30,254 60.5 3/32 40,135 160.5 40,135 160.5 33,412 133.6 21,433 68.6 20,170 56.5 1/8 30,102 156.5 30,102 156.5 25,059 130.3 16,075 70.7 15,127 54.5 3/16 20,068 128.4 20,068 128.4 16,706 106.9 10,716 72.9 10,085 52.4 1/4 15,051 216.7 15,051 216.7 12,530 180.4 8,037 93.2 7,564 78.7 3/8 10,034 224.8 10,034 224.8 8,353 187.1 5,358 96.4 5,042 78.7 1/2 7,525 213.7 7,525 213.7 6,265 177.9 4,019 93.2 3,782 75.6 1. The indicated speeds and feeds are for high speed light milling for use with high speed/high precision machining centers. 2. Do not use flammable fluids because tools with considerable wear can cause sparks. 3. We recommend using air blow. When using cutting fluids, use a high quality fluid with high smoke retardant. WWW.OSGTOOL.COM End Mill Technical 1031

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta