Общий каталог Osawa 2018 - страница 690

Навигация

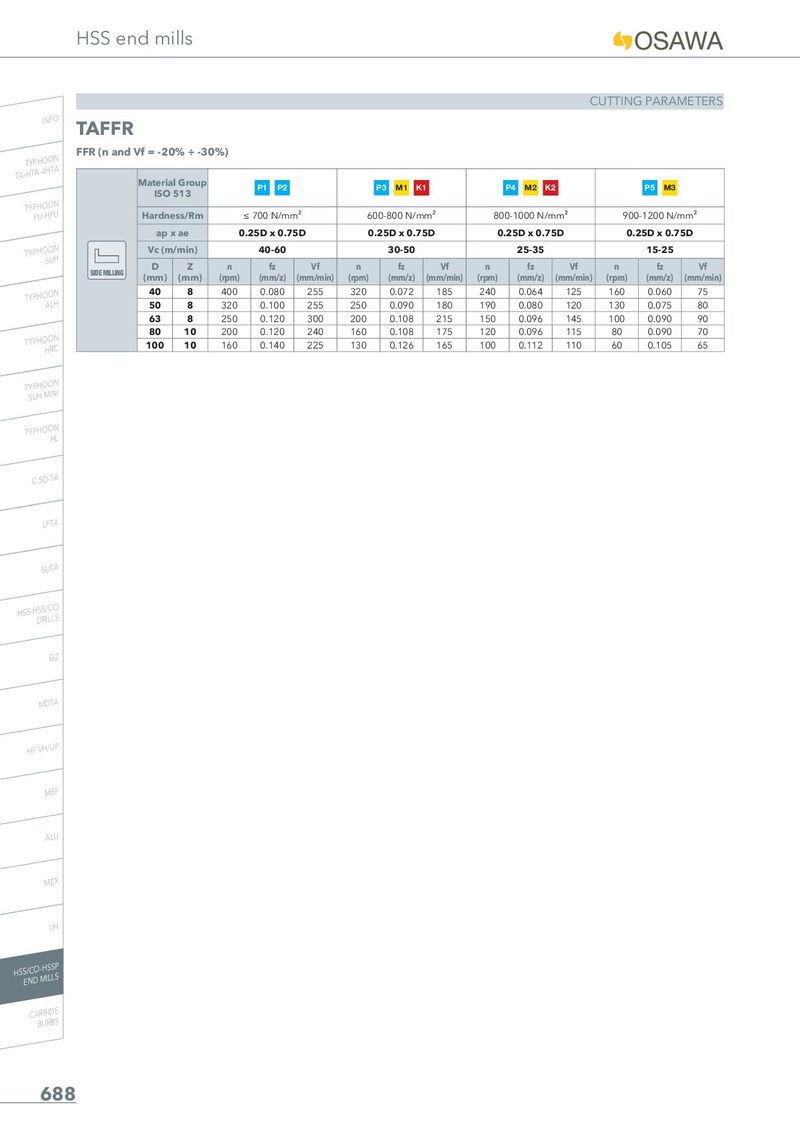

HSS end mills CUTTING PARAMETERS INFO TAFFR TA-THYTPAH-4OHOTNA FFR (n and Vf = -20% ÷ -30%) Material Group P1 P2 P3 M1 K1 P4 M2 K2 P5 M3 ISO 513 TYPPHUO-HOPNU Hardness/Rm ≤ 700 N/mm² 600-800 N/mm² 800-1000 N/mm² 900-1200 N/mm² ap x ae 0.25D x 0.75D 0.25D x 0.75D 0.25D x 0.75D 0.25D x 0.75D TYPHOSOUNH Vc (m/min) 40-60 30-50 25-35 15-25 SIDE MILLING D Z n fz Vf n fz Vf n fz Vf n fz Vf (mm) (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) TYPHOAOLNH 40 8 400 0.080 255 320 0.072 185 240 0.064 125 160 0.060 75 50 8 320 0.100 255 250 0.090 180 190 0.080 120 130 0.075 80 63 8 250 0.120 300 200 0.108 215 150 0.096 145 100 0.090 90 TYPHOHORNC 80 10 200 0.120 240 160 0.108 175 120 0.096 115 80 0.090 70 100 10 160 0.140 225 130 0.126 165 100 0.112 110 60 0.105 65 TSYUPHHOMOINNI TYPHOOHNL C-SD-TA LFTA SUTA HSS-HDSSR/ILCLOS G2 MDTA HF VH/UP MEF ALU MEX UH HSSE/NCDO-MHISLSLPS CARBIDE BURRS 688

Общий каталог Osawa 2021

Общий каталог Osawa 2021