Общий каталог Osawa 2018 - страница 678

Навигация

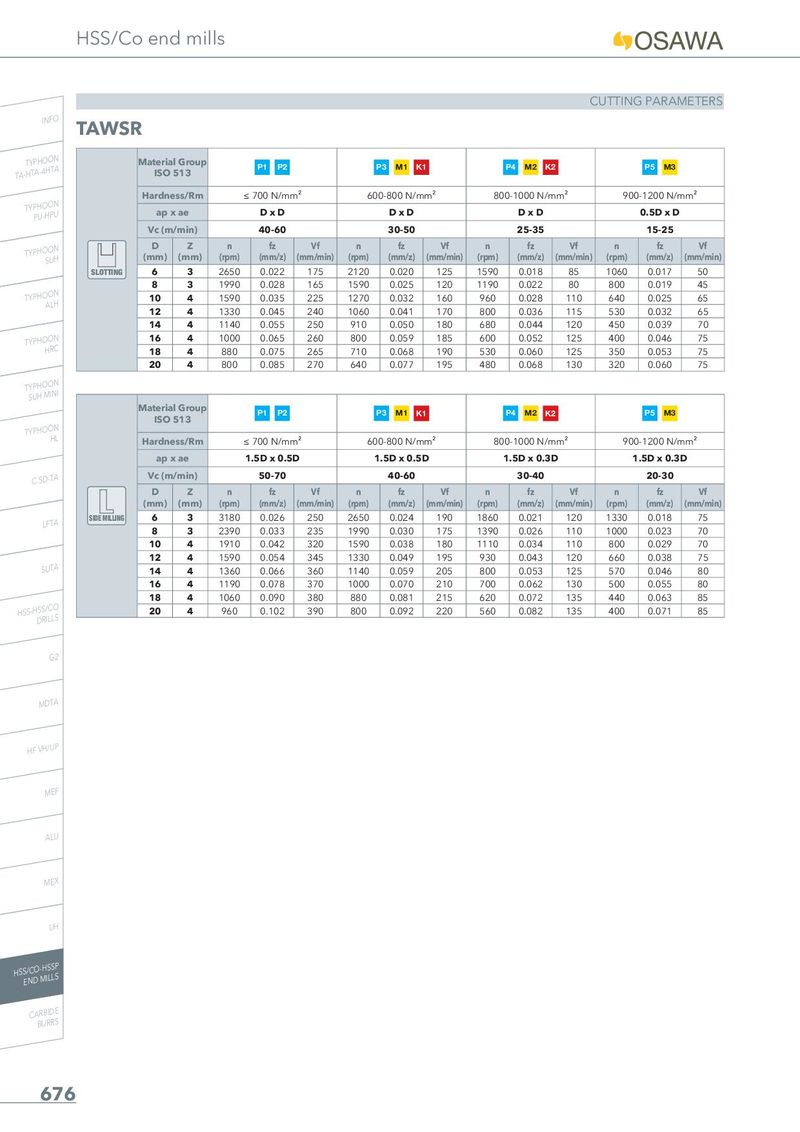

HSS/Co end mills CUTTING PARAMETERS INFO TAWSR TA-THYTPAH-4OHOTNA Material Group P1 P2 P3 M1 K1 P4 M2 K2 P5 M3 ISO 513 Hardness/Rm ≤ 700 N/mm² 600-800 N/mm² 800-1000 N/mm² 900-1200 N/mm² TYPPHUO-HOPNU ap x ae DxD DxD DxD 0.5D x D Vc (m/min) 40-60 30-50 25-35 15-25 TYPHOSOUNH D Z n fz Vf n fz Vf n fz Vf n fz Vf (mm) (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) SLOTTING 6 3 2650 0.022 175 2120 0.020 125 1590 0.018 85 1060 0.017 50 8 3 1990 0.028 165 1590 0.025 120 1190 0.022 80 800 0.019 45 TYPHOAOLNH 10 4 1590 0.035 225 1270 0.032 160 960 0.028 110 640 0.025 65 12 4 1330 0.045 240 1060 0.041 170 800 0.036 115 530 0.032 65 14 4 1140 0.055 250 910 0.050 180 680 0.044 120 450 0.039 70 TYPHOHORNC 16 4 1000 0.065 260 800 0.059 185 600 0.052 125 400 0.046 75 18 4 880 0.075 265 710 0.068 190 530 0.060 125 350 0.053 75 20 4 800 0.085 270 640 0.077 195 480 0.068 130 320 0.060 75 TSYUPHHOMOINNI Material Group P1 P2 P3 M1 K1 P4 M2 K2 P5 M3 ISO 513 TYPHOOHNL Hardness/Rm ≤ 700 N/mm² 600-800 N/mm² 800-1000 N/mm² 900-1200 N/mm² ap x ae 1.5D x 0.5D 1.5D x 0.5D 1.5D x 0.3D 1.5D x 0.3D C-SD-TA Vc (m/min) 50-70 40-60 30-40 20-30 D Z n fz Vf n fz Vf n fz Vf n fz Vf (mm) (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) LFTA SIDE MILLING 6 3 3180 0.026 250 2650 0.024 190 1860 0.021 120 1330 0.018 75 8 3 2390 0.033 235 1990 0.030 175 1390 0.026 110 1000 0.023 70 10 4 1910 0.042 320 1590 0.038 180 1110 0.034 110 800 0.029 70 12 4 1590 0.054 345 1330 0.049 195 930 0.043 120 660 0.038 75 SUTA 14 4 1360 0.066 360 1140 0.059 205 800 0.053 125 570 0.046 80 16 4 1190 0.078 370 1000 0.070 210 700 0.062 130 500 0.055 80 18 4 1060 0.090 380 880 0.081 215 620 0.072 135 440 0.063 85 HSS-HDSSR/ILCLOS 20 4 960 0.102 390 800 0.092 220 560 0.082 135 400 0.071 85 G2 MDTA HF VH/UP MEF ALU MEX UH HSSE/NCDO-MHISLSLPS CARBIDE BURRS 676

Общий каталог Osawa 2021

Общий каталог Osawa 2021