Общий каталог Osawa 2018 - страница 672

Навигация

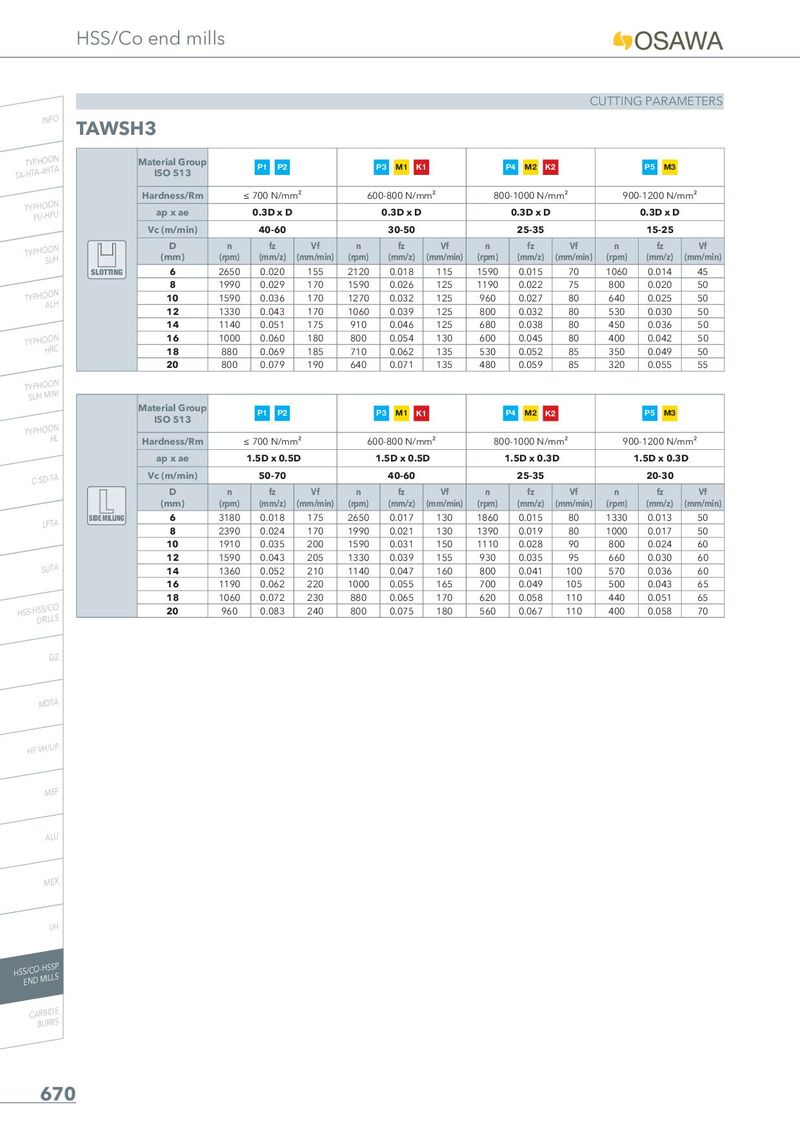

HSS/Co end mills CUTTING PARAMETERS INFO TAWSH3 TA-THYTPAH-4OHOTNA Material Group P1 P2 P3 M1 K1 P4 M2 K2 P5 M3 ISO 513 Hardness/Rm ≤ 700 N/mm² 600-800 N/mm² 800-1000 N/mm² 900-1200 N/mm² TYPPHUO-HOPNU ap x ae 0.3D x D 0.3D x D 0.3D x D 0.3D x D Vc (m/min) 40-60 30-50 25-35 15-25 TYPHOSOUNH D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) SLOTTING 6 2650 0.020 155 2120 0.018 115 1590 0.015 70 1060 0.014 45 8 1990 0.029 170 1590 0.026 125 1190 0.022 75 800 0.020 50 TYPHOAOLNH 10 1590 0.036 170 1270 0.032 125 960 0.027 80 640 0.025 50 12 1330 0.043 170 1060 0.039 125 800 0.032 80 530 0.030 50 14 1140 0.051 175 910 0.046 125 680 0.038 80 450 0.036 50 TYPHOHORNC 16 1000 0.060 180 800 0.054 130 600 0.045 80 400 0.042 50 18 880 0.069 185 710 0.062 135 530 0.052 85 350 0.049 50 20 800 0.079 190 640 0.071 135 480 0.059 85 320 0.055 55 TSYUPHHOMOINNI Material Group P1 P2 P3 M1 K1 P4 M2 K2 P5 M3 ISO 513 TYPHOOHNL Hardness/Rm ≤ 700 N/mm² 600-800 N/mm² 800-1000 N/mm² 900-1200 N/mm² ap x ae 1.5D x 0.5D 1.5D x 0.5D 1.5D x 0.3D 1.5D x 0.3D C-SD-TA Vc (m/min) 50-70 40-60 25-35 20-30 D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) LFTA SIDE MILLING 6 3180 0.018 175 2650 0.017 130 1860 0.015 80 1330 0.013 50 8 2390 0.024 170 1990 0.021 130 1390 0.019 80 1000 0.017 50 10 1910 0.035 200 1590 0.031 150 1110 0.028 90 800 0.024 60 12 1590 0.043 205 1330 0.039 155 930 0.035 95 660 0.030 60 SUTA 14 1360 0.052 210 1140 0.047 160 800 0.041 100 570 0.036 60 16 1190 0.062 220 1000 0.055 165 700 0.049 105 500 0.043 65 18 1060 0.072 230 880 0.065 170 620 0.058 110 440 0.051 65 HSS-HDSSR/ILCLOS 20 960 0.083 240 800 0.075 180 560 0.067 110 400 0.058 70 G2 MDTA HF VH/UP MEF ALU MEX UH HSSE/NCDO-MHISLSLPS CARBIDE BURRS 670

Общий каталог Osawa 2021

Общий каталог Osawa 2021