Общий каталог Osawa 2018 - страница 553

Навигация

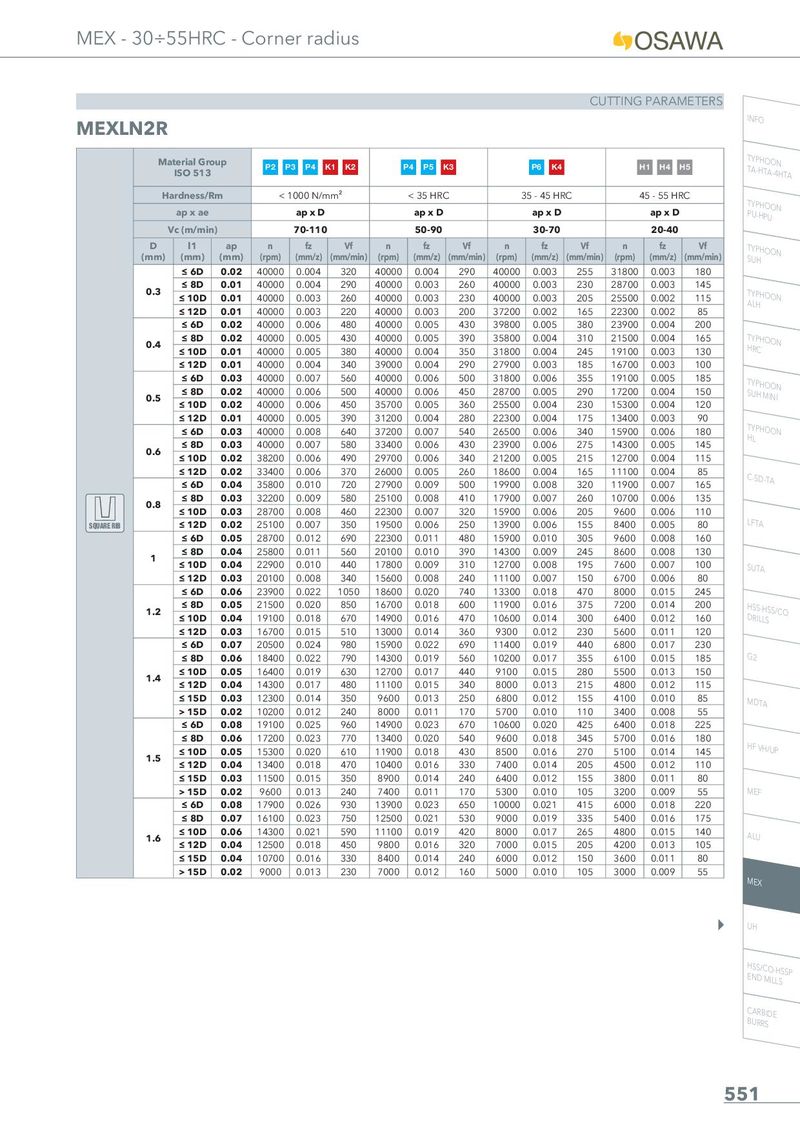

MEX - 30÷55HRC - Corner radius CUTTING PARAMETERS MEXLN2R INFO Material Group P2 P3 P4 K1 K2 P4 P5 K3 P6 K4 H1 H4 H5 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm < 1000 N/mm² < 35 HRC 35 - 45 HRC 45 - 55 HRC TPYUP-HHPOUON ap x ae ap x D ap x D ap x D ap x D Vc (m/min) 70-110 50-90 30-70 20-40 D l1 ap n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON (mm) (mm) (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) ≤ 6D 0.02 40000 0.004 320 40000 0.004 290 40000 0.003 255 31800 0.003 180 0.3 ≤ 8D 0.01 40000 0.004 290 40000 0.003 260 40000 0.003 230 28700 0.003 145 TAYLPHHOON ≤ 10D 0.01 40000 0.003 260 40000 0.003 230 40000 0.003 205 25500 0.002 115 ≤ 12D 0.01 40000 0.003 220 40000 0.003 200 37200 0.002 165 22300 0.002 85 ≤ 6D 0.02 40000 0.006 480 40000 0.005 430 39800 0.005 380 23900 0.004 200 0.4 ≤ 8D 0.02 40000 0.005 430 40000 0.005 390 35800 0.004 310 21500 0.004 165 THYRPCHOON ≤ 10D 0.01 40000 0.005 380 40000 0.004 350 31800 0.004 245 19100 0.003 130 ≤ 12D 0.01 40000 0.004 340 39000 0.004 290 27900 0.003 185 16700 0.003 100 ≤ 6D 0.03 40000 0.007 560 40000 0.006 500 31800 0.006 355 19100 0.005 185 TSUYPHHMOIONIN 0.5 ≤ 8D 0.02 40000 0.006 500 40000 0.006 450 28700 0.005 290 17200 0.004 150 ≤ 10D 0.02 40000 0.006 450 35700 0.005 360 25500 0.004 230 15300 0.004 120 ≤ 12D 0.01 40000 0.005 390 31200 0.004 280 22300 0.004 175 13400 0.003 90 ≤ 6D 0.03 40000 0.008 640 37200 0.007 540 26500 0.006 340 15900 0.006 180 THYLPHOON 0.6 ≤ 8D 0.03 40000 0.007 580 33400 0.006 430 23900 0.006 275 14300 0.005 145 ≤ 10D 0.02 38200 0.006 490 29700 0.006 340 21200 0.005 215 12700 0.004 115 ≤ 12D 0.02 33400 0.006 370 26000 0.005 260 18600 0.004 165 11100 0.004 85 C-SD-TA ≤ 6D 0.04 35800 0.010 720 27900 0.009 500 19900 0.008 320 11900 0.007 165 0.8 ≤ 8D 0.03 32200 0.009 580 25100 0.008 410 17900 0.007 260 10700 0.006 135 ≤ 10D 0.03 28700 0.008 460 22300 0.007 320 15900 0.006 205 9600 0.006 110 SQUARE RIB ≤ 12D 0.02 25100 0.007 350 19500 0.006 250 13900 0.006 155 8400 0.005 80 LFTA ≤ 6D 0.05 28700 0.012 690 22300 0.011 480 15900 0.010 305 9600 0.008 160 1 ≤ 8D 0.04 25800 0.011 560 20100 0.010 390 14300 0.009 245 8600 0.008 130 ≤ 10D 0.04 22900 0.010 440 17800 0.009 310 12700 0.008 195 7600 0.007 100 SUTA ≤ 12D 0.03 20100 0.008 340 15600 0.008 240 11100 0.007 150 6700 0.006 80 ≤ 6D 0.06 23900 0.022 1050 18600 0.020 740 13300 0.018 470 8000 0.015 245 1.2 ≤ 8D 0.05 21500 0.020 850 16700 0.018 600 11900 0.016 375 7200 0.014 200 HDSRSIL-LHSSS/CO ≤ 10D 0.04 19100 0.018 670 14900 0.016 470 10600 0.014 300 6400 0.012 160 ≤ 12D 0.03 16700 0.015 510 13000 0.014 360 9300 0.012 230 5600 0.011 120 ≤ 6D 0.07 20500 0.024 980 15900 0.022 690 11400 0.019 440 6800 0.017 230 ≤ 8D 0.06 18400 0.022 790 14300 0.019 560 10200 0.017 355 6100 0.015 185 G2 1.4 ≤ 10D 0.05 16400 0.019 630 12700 0.017 440 9100 0.015 280 5500 0.013 150 ≤ 12D 0.04 14300 0.017 480 11100 0.015 340 8000 0.013 215 4800 0.012 115 ≤ 15D 0.03 12300 0.014 350 9600 0.013 250 6800 0.012 155 4100 0.010 85 MDTA > 15D 0.02 10200 0.012 240 8000 0.011 170 5700 0.010 110 3400 0.008 55 ≤ 6D 0.08 19100 0.025 960 14900 0.023 670 10600 0.020 425 6400 0.018 225 ≤ 8D 0.06 17200 0.023 770 13400 0.020 540 9600 0.018 345 5700 0.016 180 HF VH/UP 1.5 ≤ 10D 0.05 15300 0.020 610 11900 0.018 430 8500 0.016 270 5100 0.014 145 ≤ 12D 0.04 13400 0.018 470 10400 0.016 330 7400 0.014 205 4500 0.012 110 ≤ 15D 0.03 11500 0.015 350 8900 0.014 240 6400 0.012 155 3800 0.011 80 > 15D 0.02 9600 0.013 240 7400 0.011 170 5300 0.010 105 3200 0.009 55 MEF ≤ 6D 0.08 17900 0.026 930 13900 0.023 650 10000 0.021 415 6000 0.018 220 ≤ 8D 0.07 16100 0.023 750 12500 0.021 530 9000 0.019 335 5400 0.016 175 1.6 ≤ 10D 0.06 14300 0.021 590 11100 0.019 420 8000 0.017 265 4800 0.015 140 ALU ≤ 12D 0.04 12500 0.018 450 9800 0.016 320 7000 0.015 205 4200 0.013 105 ≤ 15D 0.04 10700 0.016 330 8400 0.014 240 6000 0.012 150 3600 0.011 80 > 15D 0.02 9000 0.013 230 7000 0.012 160 5000 0.010 105 3000 0.009 55 MEX UH HENSSD/CMOIL-LHSSSP CBUARRRBSIDE 551

Общий каталог Osawa 2021

Общий каталог Osawa 2021