Общий каталог Osawa 2018 - страница 517

Навигация

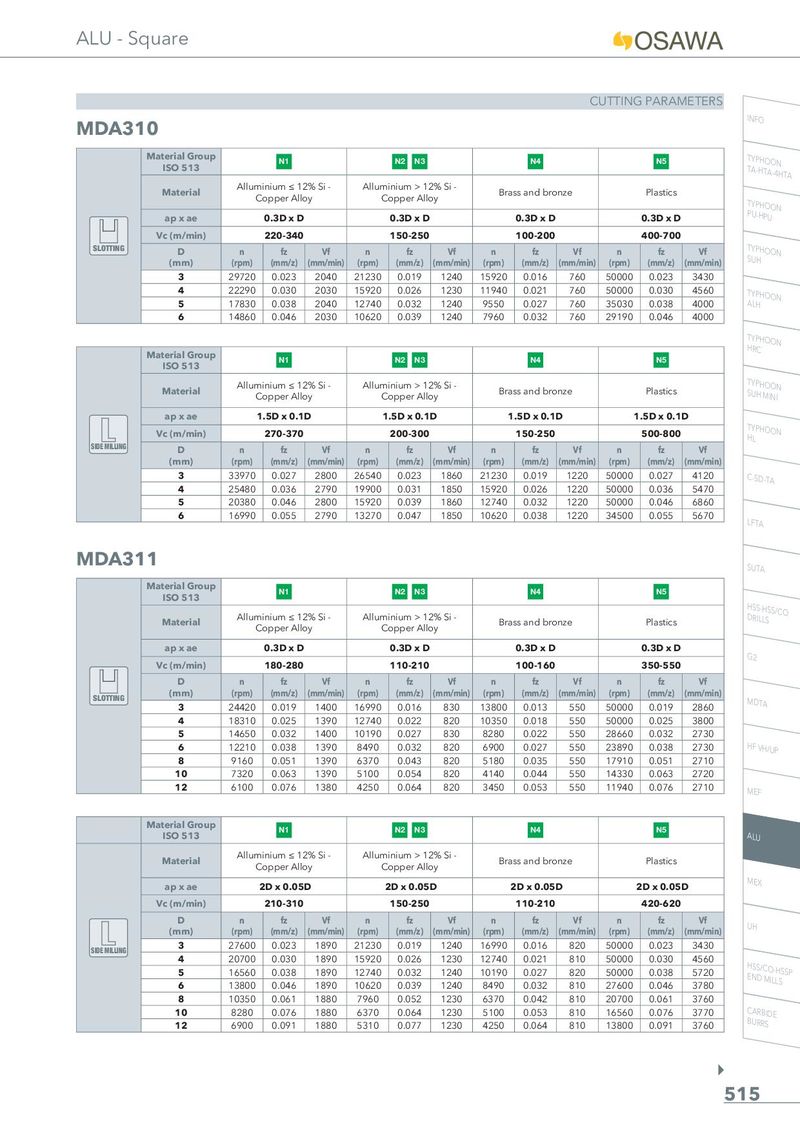

ALU - Square CUTTING PARAMETERS MDA310 INFO Material Group N1 N2 N3 N4 N5 TTYAP-HHTOAO-4NHTA ISO 513 Material Alluminium ≤ 12% Si - Alluminium > 12% Si - Brass and bronze Plastics Copper Alloy Copper Alloy TPYUP-HHPOUON ap x ae 0.3D x D 0.3D x D 0.3D x D 0.3D x D Vc (m/min) 220-340 150-250 100-200 400-700 SLOTTING D n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 3 29720 0.023 2040 21230 0.019 1240 15920 0.016 760 50000 0.023 3430 4 22290 0.030 2030 15920 0.026 1230 11940 0.021 760 50000 0.030 4560 TAYLPHHOON 5 17830 0.038 2040 12740 0.032 1240 9550 0.027 760 35030 0.038 4000 6 14860 0.046 2030 10620 0.039 1240 7960 0.032 760 29190 0.046 4000 Material Group THYRPCHOON ISO 513 N1 N2 N3 N4 N5 Material Alluminium ≤ 12% Si - Alluminium > 12% Si - Brass and bronze Plastics TSUYPHHMOIONIN Copper Alloy Copper Alloy ap x ae 1.5D x 0.1D 1.5D x 0.1D 1.5D x 0.1D 1.5D x 0.1D Vc (m/min) 270-370 200-300 150-250 500-800 THYLPHOON SIDE MILLING D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 3 33970 0.027 2800 26540 0.023 1860 21230 0.019 1220 50000 0.027 4120 C-SD-TA 4 25480 0.036 2790 19900 0.031 1850 15920 0.026 1220 50000 0.036 5470 5 20380 0.046 2800 15920 0.039 1860 12740 0.032 1220 50000 0.046 6860 6 16990 0.055 2790 13270 0.047 1850 10620 0.038 1220 34500 0.055 5670 LFTA MDA311 SUTA Material Group N1 N2 N3 N4 N5 ISO 513 Material Alluminium ≤ 12% Si - Alluminium > 12% Si - Brass and bronze Plastics HDSRSIL-LHSSS/CO Copper Alloy Copper Alloy ap x ae 0.3D x D 0.3D x D 0.3D x D 0.3D x D G2 Vc (m/min) 180-280 110-210 100-160 350-550 D n fz Vf n fz Vf n fz Vf n fz Vf SLOTTING (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) MDTA 3 24420 0.019 1400 16990 0.016 830 13800 0.013 550 50000 0.019 2860 4 18310 0.025 1390 12740 0.022 820 10350 0.018 550 50000 0.025 3800 5 14650 0.032 1400 10190 0.027 830 8280 0.022 550 28660 0.032 2730 6 12210 0.038 1390 8490 0.032 820 6900 0.027 550 23890 0.038 2730 HF VH/UP 8 9160 0.051 1390 6370 0.043 820 5180 0.035 550 17910 0.051 2710 10 7320 0.063 1390 5100 0.054 820 4140 0.044 550 14330 0.063 2720 12 6100 0.076 1380 4250 0.064 820 3450 0.053 550 11940 0.076 2710 MEF Material Group N1 N2 N3 N4 N5 ISO 513 ALU Material Alluminium ≤ 12% Si - Alluminium > 12% Si - Brass and bronze Plastics Copper Alloy Copper Alloy ap x ae 2D x 0.05D 2D x 0.05D 2D x 0.05D 2D x 0.05D MEX Vc (m/min) 210-310 150-250 110-210 420-620 D n fz Vf n fz Vf n fz Vf n fz Vf UH (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) SIDE MILLING 3 27600 0.023 1890 21230 0.019 1240 16990 0.016 820 50000 0.023 3430 4 20700 0.030 1890 15920 0.026 1230 12740 0.021 810 50000 0.030 4560 HENSSD/CMOIL-LHSSSP 5 16560 0.038 1890 12740 0.032 1240 10190 0.027 820 50000 0.038 5720 6 13800 0.046 1890 10620 0.039 1240 8490 0.032 810 27600 0.046 3780 8 10350 0.061 1880 7960 0.052 1230 6370 0.042 810 20700 0.061 3760 10 8280 0.076 1880 6370 0.064 1230 5100 0.053 810 16560 0.076 3770 CBUARRRBSIDE 12 6900 0.091 1880 5310 0.077 1230 4250 0.064 810 13800 0.091 3760 515

Общий каталог Osawa 2021

Общий каталог Osawa 2021