Общий каталог Osawa 2018 - страница 510

Навигация

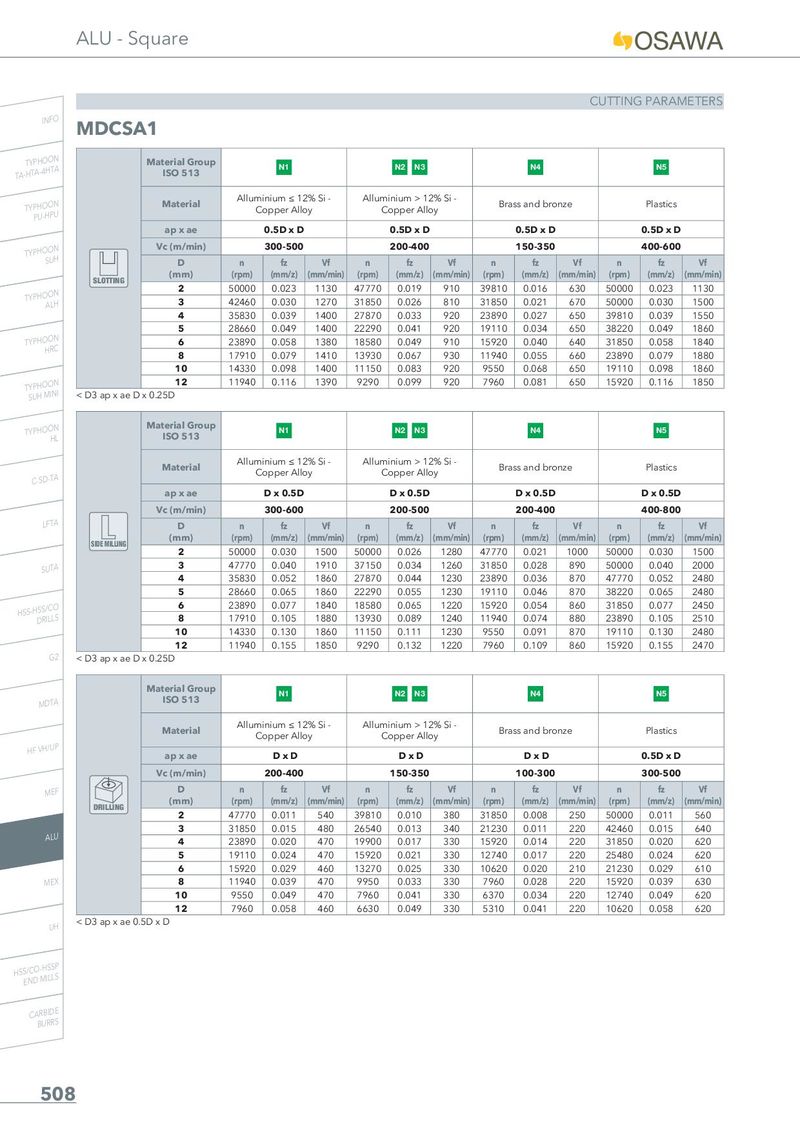

ALU - Square CUTTING PARAMETERS INFO MDCSA1 TA-THYTPAH-4OHOTNA Material Group N1 N2 N3 N4 N5 ISO 513 TYPPHUO-HOPNU Material Alluminium ≤ 12% Si - Alluminium > 12% Si - Brass and bronze Plastics Copper Alloy Copper Alloy ap x ae 0.5D x D 0.5D x D 0.5D x D 0.5D x D TYPHOSOUNH Vc (m/min) 300-500 200-400 150-350 400-600 D n fz Vf n fz Vf n fz Vf n fz Vf SLOTTING (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) TYPHOAOLNH 2 50000 0.023 1130 47770 0.019 910 39810 0.016 630 50000 0.023 1130 3 42460 0.030 1270 31850 0.026 810 31850 0.021 670 50000 0.030 1500 4 35830 0.039 1400 27870 0.033 920 23890 0.027 650 39810 0.039 1550 5 28660 0.049 1400 22290 0.041 920 19110 0.034 650 38220 0.049 1860 TYPHOHORNC 6 23890 0.058 1380 18580 0.049 910 15920 0.040 640 31850 0.058 1840 8 17910 0.079 1410 13930 0.067 930 11940 0.055 660 23890 0.079 1880 10 14330 0.098 1400 11150 0.083 920 9550 0.068 650 19110 0.098 1860 TSYUPHHOMOINNI 12 11940 0.116 1390 9290 0.099 920 7960 0.081 650 15920 0.116 1850 < D3 ap x ae D x 0.25D TYPHOOHNL Material Group N1 N2 N3 N4 N5 ISO 513 Material Alluminium ≤ 12% Si - Alluminium > 12% Si - Brass and bronze Plastics C-SD-TA Copper Alloy Copper Alloy ap x ae D x 0.5D D x 0.5D D x 0.5D D x 0.5D Vc (m/min) 300-600 200-500 200-400 400-800 LFTA D n fz Vf n fz Vf n fz Vf n fz Vf SIDE MILLING (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 2 50000 0.030 1500 50000 0.026 1280 47770 0.021 1000 50000 0.030 1500 SUTA 3 47770 0.040 1910 37150 0.034 1260 31850 0.028 890 50000 0.040 2000 4 35830 0.052 1860 27870 0.044 1230 23890 0.036 870 47770 0.052 2480 5 28660 0.065 1860 22290 0.055 1230 19110 0.046 870 38220 0.065 2480 HSS-HDSSR/ILCLOS 6 23890 0.077 1840 18580 0.065 1220 15920 0.054 860 31850 0.077 2450 8 17910 0.105 1880 13930 0.089 1240 11940 0.074 880 23890 0.105 2510 10 14330 0.130 1860 11150 0.111 1230 9550 0.091 870 19110 0.130 2480 12 11940 0.155 1850 9290 0.132 1220 7960 0.109 860 15920 0.155 2470 G2 < D3 ap x ae D x 0.25D Material Group N1 N2 N3 N4 N5 MDTA ISO 513 Material Alluminium ≤ 12% Si - Alluminium > 12% Si - Brass and bronze Plastics Copper Alloy Copper Alloy HF VH/UP ap x ae DxD DxD DxD 0.5D x D Vc (m/min) 200-400 150-350 100-300 300-500 MEF D n fz Vf n fz Vf n fz Vf n fz Vf DRILLING (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 2 47770 0.011 540 39810 0.010 380 31850 0.008 250 50000 0.011 560 ALU 3 31850 0.015 480 26540 0.013 340 21230 0.011 220 42460 0.015 640 4 23890 0.020 470 19900 0.017 330 15920 0.014 220 31850 0.020 620 5 19110 0.024 470 15920 0.021 330 12740 0.017 220 25480 0.024 620 6 15920 0.029 460 13270 0.025 330 10620 0.020 210 21230 0.029 610 MEX 8 11940 0.039 470 9950 0.033 330 7960 0.028 220 15920 0.039 630 10 9550 0.049 470 7960 0.041 330 6370 0.034 220 12740 0.049 620 12 7960 0.058 460 6630 0.049 330 5310 0.041 220 10620 0.058 620 UH < D3 ap x ae 0.5D xD HSSE/NCDO-MHISLSLPS CARBIDE BURRS 508

Общий каталог Osawa 2021

Общий каталог Osawa 2021