Общий каталог Osawa 2018 - страница 455

Навигация

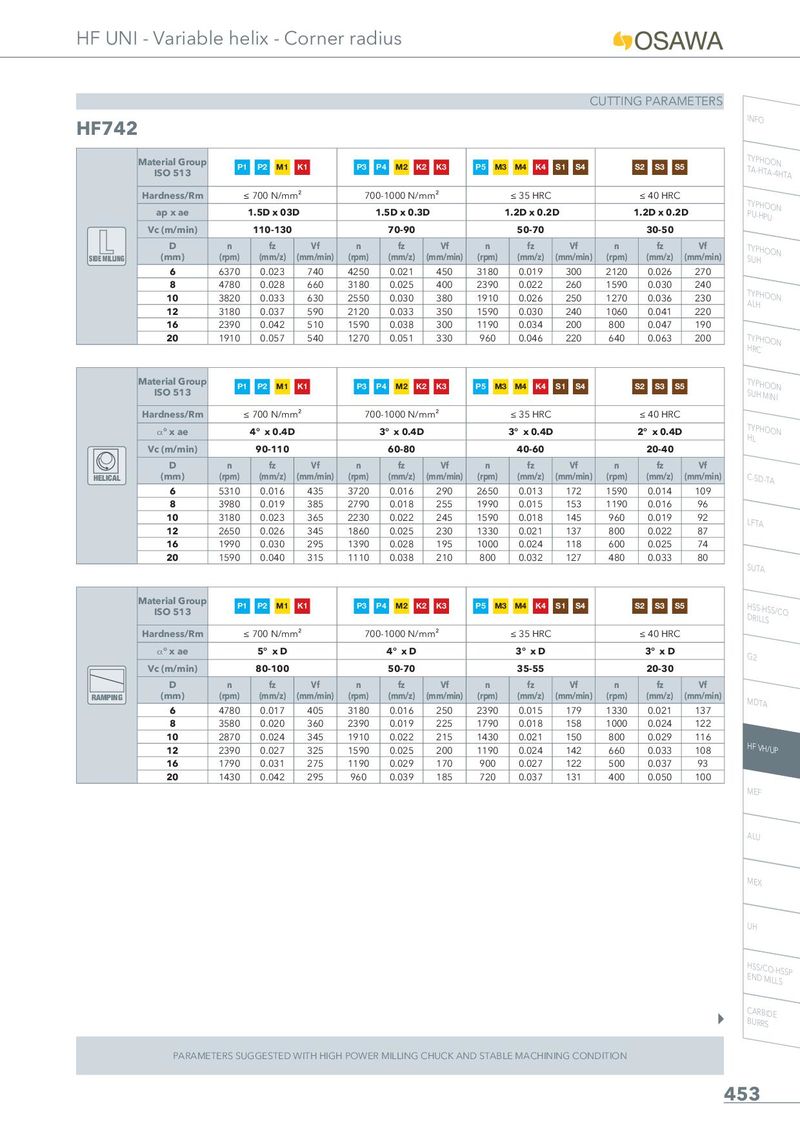

HF UNI - Variable helix - Corner radius CUTTING PARAMETERS HF742 INFO Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC TPYUP-HHPOUON ap x ae 1.5D x 03D 1.5D x 0.3D 1.2D x 0.2D 1.2D x 0.2D Vc (m/min) 110-130 70-90 50-70 30-50 D n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON SIDE MILLING (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 6 6370 0.023 740 4250 0.021 450 3180 0.019 300 2120 0.026 270 8 4780 0.028 660 3180 0.025 400 2390 0.022 260 1590 0.030 240 TAYLPHHOON 10 3820 0.033 630 2550 0.030 380 1910 0.026 250 1270 0.036 230 12 3180 0.037 590 2120 0.033 350 1590 0.030 240 1060 0.041 220 16 2390 0.042 510 1590 0.038 300 1190 0.034 200 800 0.047 190 20 1910 0.057 540 1270 0.051 330 960 0.046 220 640 0.063 200 THYRPCHOON Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 TSUYPHHMOIONIN ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC _° x ae 4° x 0.4D 3° x 0.4D 3° x 0.4D 2° x 0.4D THYLPHOON Vc (m/min) 90-110 60-80 40-60 20-40 D n fz Vf n fz Vf n fz Vf n fz Vf HELICAL (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) C-SD-TA 6 5310 0.016 435 3720 0.016 290 2650 0.013 172 1590 0.014 109 8 3980 0.019 385 2790 0.018 255 1990 0.015 153 1190 0.016 96 10 3180 0.023 365 2230 0.022 245 1590 0.018 145 960 0.019 92 LFTA 12 2650 0.026 345 1860 0.025 230 1330 0.021 137 800 0.022 87 16 1990 0.030 295 1390 0.028 195 1000 0.024 118 600 0.025 74 20 1590 0.040 315 1110 0.038 210 800 0.032 127 480 0.033 80 SUTA Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 HDSRSIL-LHSSS/CO ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC _° x ae 5° x D 4° x D 3° x D 3° x D G2 Vc (m/min) 80-100 50-70 35-55 20-30 D n fz Vf n fz Vf n fz Vf n fz Vf RAMPING (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) MDTA 6 4780 0.017 405 3180 0.016 250 2390 0.015 179 1330 0.021 137 8 3580 0.020 360 2390 0.019 225 1790 0.018 158 1000 0.024 122 10 2870 0.024 345 1910 0.022 215 1430 0.021 150 800 0.029 116 12 2390 0.027 325 1590 0.025 200 1190 0.024 142 660 0.033 108 HF VH/UP 16 1790 0.031 275 1190 0.029 170 900 0.027 122 500 0.037 93 20 1430 0.042 295 960 0.039 185 720 0.037 131 400 0.050 100 MEF ALU MEX UH HENSSD/CMOIL-LHSSSP CBUARRRBSIDE PARAMETERS SUGGESTED WITH HIGH POWER MILLING CHUCK AND STABLE MACHINING CONDITION 453

Общий каталог Osawa 2021

Общий каталог Osawa 2021