Общий каталог Osawa 2018 - страница 442

Навигация

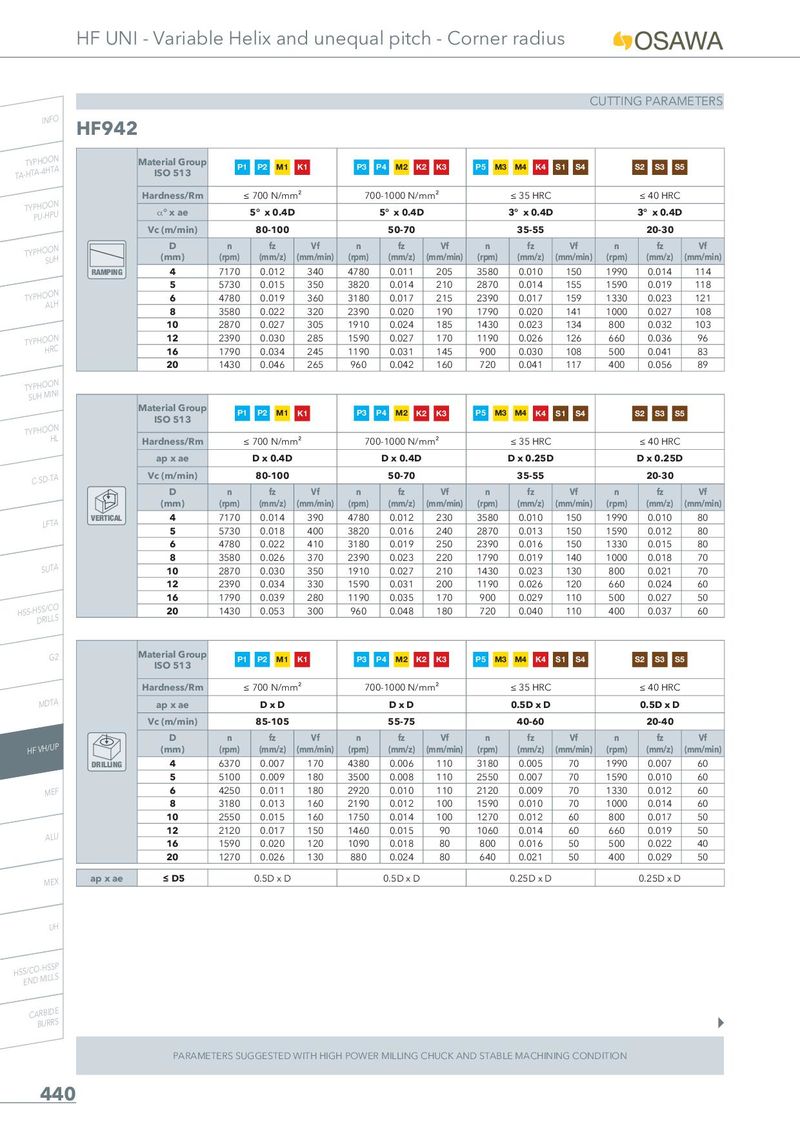

HF UNI - Variable Helix and unequal pitch - Corner radius CUTTING PARAMETERS INFO HF942 TA-THYTPAH-4OHOTNA Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC TYPPHUO-HOPNU _° x ae 5° x 0.4D 5° x 0.4D 3° x 0.4D 3° x 0.4D Vc (m/min) 80-100 50-70 35-55 20-30 TYPHOSOUNH D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) RAMPING 4 7170 0.012 340 4780 0.011 205 3580 0.010 150 1990 0.014 114 5 5730 0.015 350 3820 0.014 210 2870 0.014 155 1590 0.019 118 TYPHOAOLNH 6 4780 0.019 360 3180 0.017 215 2390 0.017 159 1330 0.023 121 8 3580 0.022 320 2390 0.020 190 1790 0.020 141 1000 0.027 108 10 2870 0.027 305 1910 0.024 185 1430 0.023 134 800 0.032 103 TYPHOHORNC 12 2390 0.030 285 1590 0.027 170 1190 0.026 126 660 0.036 96 16 1790 0.034 245 1190 0.031 145 900 0.030 108 500 0.041 83 20 1430 0.046 265 960 0.042 160 720 0.041 117 400 0.056 89 TSYUPHHOMOINNI Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 ISO 513 TYPHOOHNL Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC ap x ae D x 0.4D D x 0.4D D x 0.25D D x 0.25D C-SD-TA Vc (m/min) 80-100 50-70 35-55 20-30 D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) LFTA VERTICAL 4 7170 0.014 390 4780 0.012 230 3580 0.010 150 1990 0.010 80 5 5730 0.018 400 3820 0.016 240 2870 0.013 150 1590 0.012 80 6 4780 0.022 410 3180 0.019 250 2390 0.016 150 1330 0.015 80 8 3580 0.026 370 2390 0.023 220 1790 0.019 140 1000 0.018 70 SUTA 10 2870 0.030 350 1910 0.027 210 1430 0.023 130 800 0.021 70 12 2390 0.034 330 1590 0.031 200 1190 0.026 120 660 0.024 60 16 1790 0.039 280 1190 0.035 170 900 0.029 110 500 0.027 50 HSS-HDSSR/ILCLOS 20 1430 0.053 300 960 0.048 180 720 0.040 110 400 0.037 60 G2 Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC MDTA ap x ae DxD DxD 0.5D x D 0.5D x D Vc (m/min) 85-105 55-75 40-60 20-40 D n fz Vf n fz Vf n fz Vf n fz Vf HF VH/UP (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) DRILLING 4 6370 0.007 170 4380 0.006 110 3180 0.005 70 1990 0.007 60 5 5100 0.009 180 3500 0.008 110 2550 0.007 70 1590 0.010 60 MEF 6 4250 0.011 180 2920 0.010 110 2120 0.009 70 1330 0.012 60 8 3180 0.013 160 2190 0.012 100 1590 0.010 70 1000 0.014 60 10 2550 0.015 160 1750 0.014 100 1270 0.012 60 800 0.017 50 ALU 12 2120 0.017 150 1460 0.015 90 1060 0.014 60 660 0.019 50 16 1590 0.020 120 1090 0.018 80 800 0.016 50 500 0.022 40 20 1270 0.026 130 880 0.024 80 640 0.021 50 400 0.029 50 MEX ap x ae ≤ D5 0.5D x D 0.5D x D 0.25D x D 0.25D x D UH HSSE/NCDO-MHISLSLPS CARBIDE BURRS PARAMETERS SUGGESTED WITH HIGH POWER MILLING CHUCK AND STABLE MACHINING CONDITION 440

Общий каталог Osawa 2021

Общий каталог Osawa 2021