Общий каталог Lamina Technologies 2019 - 2020 - страница 185

Навигация

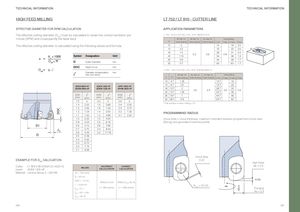

TECHNICAL INFORMATION TECHNICAL INFORMATION HIGH FEED MILLING LT 752 / LT 910 - CUTTER LINE EFFECTIVE DIAMETER FOR RPM The effective cutting diameter (Deff) CALCULATION must be calculated n to ob=taiVnDcetfhxf xe1π0c0o0rrect revolution per APPLICATION PARAMETERSLT 752 - SHOULDER MILLING - APKT 060204-PDTR minute (RPM) and consequently the table feed. α° max. for Ap max. for Ae max. for Helical Milling Deff = D-l D linear ramping linear ramping linear plunging C min. P max. C max. P max. The effective cutting diameter is calculated using the following values and formula. 10 3 14 19 3.0 12 2.2 18 23 2.5 α° 16 1.5 26 31 2.0 n = Vc x 1000Deff x π Symbol Designation UnitDCutter Diametermm 5.2 0.6 0.9201.153439 1.8250.944491.7320.758631.7 DOC Depth of cut mm Deff = D-l Diameter compensation mm LT 910 - HIGH FEED MILLING - XPKT & XPKW 0602-HF (see chart below) α° max. for Ap max. for Ae max. for Helical Milling D D1* linear ramping linear ramping linear plunging C min. P max. C max. P max. 10 4.7 1.25 14.7 18 Symbol Designation Unit SDKX 0904-HF SDKX 1205-HF APKT 0602-HF 12 6.7 2.5 18.7 22 SDKW 0904-HF SDKW 1205-HF APKW 0602-HF 16 10.7 2 26.7 30 0.5 2.4 0.5 0.5 D Cutter Diameter mm 20 14.7 1.25 34.7 38 DOC l DOC l DOC l 25 19.7 1 44.7 48 DOC Depth of cut mm (mm) (mm) (mm) (mm) (mm) (mm) 32 26.7 0.9 58.7 62 1.5 0 2.0 0 0.5 0 Diameter compensation mm 1.4 0.22 1.8 0.66 0.4 0.32 * Flat surface on face milling = D1 (see chart below) 1.3 0.58 1.6 1.58 0.3 0.72 1.2 1.04 1.4 2.58 0.2 1.28 PROGRAMMING RADIUS 1.1 1.52 1.2 3.66 0.1 2.22 1.0 2.02 1.0 4.84 Uncut Area = Uncut thickness, maximum mismatch between programmed corner radii 0.9 2.54 0.8 6.16 (Rprog) and generated machined profile. D1 0.8 3.10 0.6 7.66 0.7 3.70 0.4 9.44 /2 0.6 4.34 0.2 11.76 D 0.5 5.06 0.4 5.82 0.3 6.72 0.2 7.74 0.1 9.06 Uncut Area EXAMPLE FOR Deff CALCUATION 0.22 High Feed Cutter: LT 903 S-W-D040/4 (D=40/Z=4)Insert:SDKX 1205-HF VALUES INCORRECT CORRECTCALCULCATIONCALCULATION Ap = 0.5 Material: Lamina Group 3 – 280 HB Vc = 120 m/min D = 40 mm DOC = 1.0 mm RPM for D=40 RPM for Deff=35.16 l = 4.84 mmDeff = D - l n = 954 rev/min n = 1085 rev/min Rprog = R1.20 RH Plunging Deff = 40 – 4.84 Ae = 2.4 Deff = 35.16 366 367 DOC

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018