Общий каталог Lamina Technologies 2019 - 2020 - страница 181

Навигация

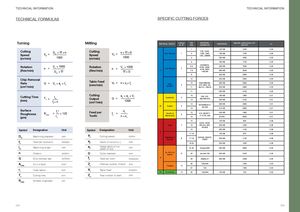

TECHNICAL INFORMATION TECHNICAL INFORMATION TECHNICAL FORMULAS SPECIFIC CUTTING FORCES Turning Millling MATERIAL GROUP LaminaGr. N° VDIGrp MATERIALEXAMPLES HARDNESS Specific cutting force, kc1(N/mm²) mc 1 125 HB 1500 0.25 CuttingSpeed Vc = Dm x π xn(m/min)1000 CuttingSpeed Vc = n x πxD(m/min)1000 C35, CK45,Non-Alloyed121020, 1045,190 HB 1700 0.251060, 28MN63250 HB18500.25 4 180 HB 1700 0.25 Rotation n = Vc x 1000(Rev/min)Dmxπ Rotation(Rev/min) n = Vc x 1000πx D Low alloyed 2P 5.6 42CRMO4,ST50, CK60,7.84140, 4340,100CR6230 HB280 HB18002040 0.250.25 9 350 HB 2900 0.25 Chip RemovalRate Q = Vc x ap x fn(cm3/min) Table Feed(mm/min) Vf = n x zc x fz 10 220 HB 2050 0.25Highallowed310X40CRMOV5,280 HBH13, M42, D3,11S6-5-2, 12NI19320 HB260029500.250.25 11 350 HB 3100 0.25 Cutting Time(min) Tc = lmfn x n CuttingOutput Q = ae x ap x Vf(cm3/min)1000 Austenitic 4 14 304, 316,14X5CRNI18-9 180 HB240 HB 18002100 0.210.21MDuplex514X2CRNIN23-4,14S31500290 HB310 HB260028000.210.21 SurfaceRoughness(µm) Rmax = fn2 x 125rε Feed perTooth fz = Vfn x zc Ferritic &Martensitic6 12 410, X6CR17,1317-4 PH, 430200 HB42 HRC 18002800 0.210.21 15 150 HB 800 0.28 GG20, GG40, Grey 7 15 EN-GJL-250, 200 HB 1000 0.28 NO30B Symbol Designation Unit Symbol Designation Unit 16 250 HB 1100 0.28 K 17.19 150 HB 870 0.28 Dm Machining diameter mm Vc Cutting speed m/min Malleable &Nodular 8 17.19 GGG40, GGG70,50005 200 HB 1150 0.28 fn Feed per revolution mm/rev ap Depth of cut (d.o.c.) mm 18.20 250 HB 1400 0.28 lm Machining length mm ae Radial depth of cut(width of cut)mm 31.32 Incoloy 800 240 HB 2600 0.25 n Rotation rev/min D Cutter diameter mm Fe, Ni & Cobased 9 33 Inconel 700 250 HB 2700 0.25 Q Chip removal rate cm3/min fz Feed per tooth mm/tooth S 34 Stellite 21 350 HB -3300 0.25 Amax d.o.c x feed mm2 Zc Effective number of teeth pcs 36 TIAL6V4 - 1400 0.23Ti bases10 rε Nose radius mm Vf Table Feed mm/min 37 T40 - 1450NFAl (>8%Si)1225TIAL6V4130 HB7000.230.25 Tc Cutting time min Zn Total number of teeth pcs Rmax Surface roughness µm 358 359

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018