Общий каталог Lamina Technologies 2019 - 2020 - страница 180

Навигация

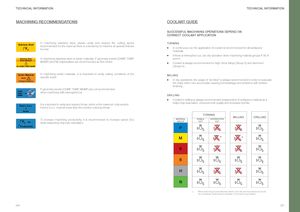

TECHNICAL INFORMATION TECHNICAL INFORMATION MACHINING RECOMMENDATIONS COOLANT GUIDE SUCCESSFUL MACHINING OPERATIONS DEPEND ON CORRECT COOLANT APPLICATION In machining stainless steel, please verify and respect the cutting speedStainless SteelVCrecommended for the insert as there is a tendency to machine at speeds that aretoo low.TURNING•In continuous cut, the application of coolant is recommended for all workpiecematerials. • If there is interrupted cut, use dry operation when machining material groups P, M, K Stainless Steel In machining stainless steel or exotic materials, P geometry inserts (CNMP, TNMP, and H. Exotic Material WNMP) and NX chipbreakers are recommended as first choice. • Coolant is always recommended for High-Temp Alloys (Group S) and Aluminum NX-CNMP-TNMP-WNMP (Group N). Exotic Material In machining exotic materials, it is important to verify cutting conditions of the MILLING Verify ! specific insert.Cutting Conditions • In dry operations, the usage of “air blow” is always recommended in order to evacuate the chips which can accumulate causing tool breakage and problems with surface finishing. P geometry inserts (CNMP, TNMP, WNMP) are not recommended CNMPTNMP when machining with interrupted cut. WNMP DRILLING • Coolant in drilling is always recommended independent of workpiece material as it Feed x d.o.c.= It is important to verify and respect Amax, which is the maximum chip section.Feed x d.o.c. must be lower than the number noted as Amax.helps chip evacuation, improves hole quality and increases tool life. Amax TURNING MILLING DRILLING VC To increase machining productivity, it is recommended to increase speed (Vc)while respecting chip size calculation. MATERIAL STABLE INTERRUPTEDGROUPCUTCUT Productivity P M * * K S H N • When machining Duplex Stainless Steels, both wet and dry operations should be considered, depending on variables in the machining process. 356 357

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018