Общий каталог Lamina Technologies 2019 - 2020 - страница 182

Навигация

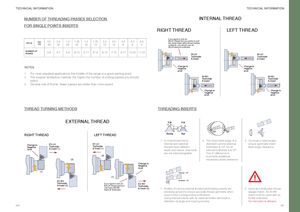

TECHNICAL INFORMATION TECHNICAL INFORMATION NUMBER OF THREADING PASSES SELECTION INTERNAL THREAD FOR SINGLE POINTS INSERTS RIGHT THREAD LEFT THREAD If you want to turn an PITCH mmTPI 0.5 0.8 1.0 1.25 1.5 1.75 2.0 2.548322420161412103.04.086 6.04 IN-LH Thread but you prefer to pullthe metal chips while thread turningoutwards, you should use an IN-LH insert & toolholder NUMBER OFPASSES 3-6 4-7 4-9 6-10 5-11 9-12 6-13 7-15 8-17 10-20 11-22 IN-LH IN-LH Toolholder Toolholder & Insert & Insert NOTES Change to Change tonegativenegative anvil anvil 1. For most standard applications the middle of the range is a good starting point. 2. The tougher workpiece material, the higher the number of cutting passes you shouldselect. IN-RH IN-RHToolholderToolholder& Insert& Insert 3. General rule of thumb: fewer passes are better than more speed. P/8 P/4 Change to Change to negativeanvil H h negativeanvil Screw Nut THREAD TURNING METHODS THREADING INSERTS EXTERNAL THREAD P/8 P/4 P/8 P/4 H h 15° 10° RIGHT THREAD LEFT THREADP/8 P/4 H h Screw NutScrewNut 15° 10° H h 1. In mos1t5t°hread for1m0°s 2. The insert relief angle of a 3. Our built-in relief angles Change toNegativeAnvilEX-LHToolholder& Insert (1) EX-LHToolholder Screw Nut& Insert (1) internal and external standard Lamina external ensure automatic insertthreads have differenttoolholder is 10°; for anflank angle clearance.depth and radius, thus toolsinternal toolholder it is 15°. are not interchangeable This 5° difference is (2) to provide additional (2) necessary radial clearance. Internal - 15° Change toNegative Internal - 15° Anvil External - 10° (1) Internal - 15° External - 10° (1) EX-RH External - 10° Toolholder& Insert (2) If you want to turn anEX-LH Thread and youonly have EX-RHInsert & ToolholderEX-RHToolholder& Insert (2)1.Profiles of Lamina internal & external threading inserts are 2. Insert and toolholder should precisely ground to ensure accurate thread geometry when always match. An IN-RH used in their corresponding toolholders. insert must be used with an Using internal inserts with an external holder will result in IN-RH toolholder. distortion of angle and insert geometry. No mismatch is allowed. 360 361

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018