Основной каталог Kyocera 2016-2017 - страница 953

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

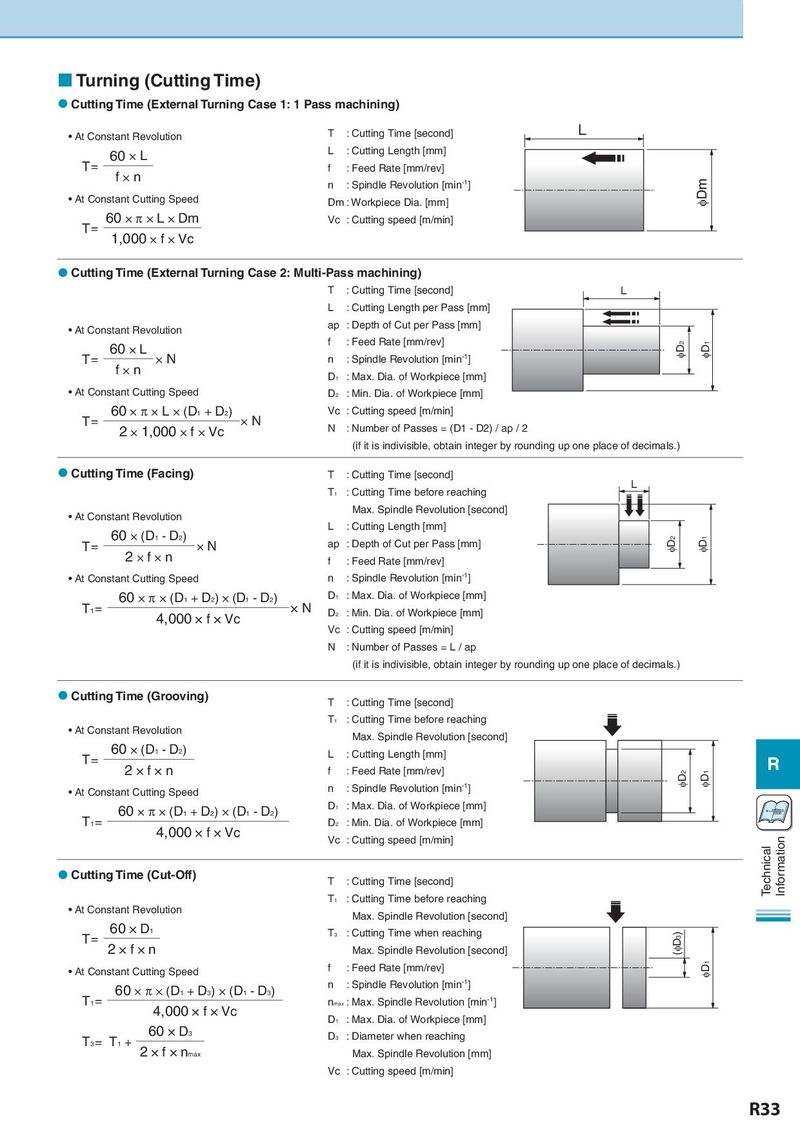

Turning (Cutting Time) Cutting Time (External Turning Case 1: 1 Pass machining) • At Constant Revolution T : Cutting Time [second] L 60 × L L : Cutting Length [mm] T= f×n f : Feed Rate [mm/rev] n : Spindle Revolution [min-1] IDm • At Constant Cutting Speed Dm : Workpiece Dia. [mm] T= 60 × π × L × Dm Vc : Cutting speed [m/min] 1,000 × f × Vc Cutting Time (External Turning Case 2: Multi-Pass machining) T : Cutting Time [second] L L : Cutting Length per Pass [mm] • At Constant Revolution ap : Depth of Cut per Pass [mm] 60 × L f : Feed Rate [mm/rev] ID2 ID1 T= ×N n : Spindle Revolution [min-1] f×n D1 : Max. Dia. of Workpiece [mm] • At Constant Cutting Speed D2 : Min. Dia. of Workpiece [mm] 60 × π × L × (D1 + D2) ×N Vc : Cutting speed [m/min] T= 2 × 1,000 × f × Vc N : Number of Passes = (D1 - D2) / ap /2 (if it is indivisible, obtain integer by rounding up one place of decimals.) Cutting Time (Facing) T : Cutting Time [second] T1 : Cutting Time before reaching L • At Constant Revolution Max. Spindle Revolution [second] 60 × (D1 - D2) L : Cutting Length [mm] T= ×N ap : Depth of Cut per Pass [mm] ID2 ID1 2×f×n f : Feed Rate [mm/rev] • At Constant Cutting Speed n : Spindle Revolution [min-1] 60 × π × (D1 + D2) × (D1 - D2) D1 : Max. Dia. of Workpiece [mm] T1 = 4,000 × f × Vc ×N D2 : Min. Dia. of Workpiece [mm] Vc : Cutting speed [m/min] N : Number of Passes = L / ap (if it is indivisible, obtain integer by rounding up one place of decimals.) Cutting Time (Grooving) T : Cutting Time [second] T1 : Cutting Time before reaching • At Constant Revolution Max. Spindle Revolution [second] T= 60 × (D1 - D2) L : Cutting Length [mm] 2×f×n f : Feed Rate [mm/rev] ID2 ID1 R • At Constant Cutting Speed n : Spindle Revolution [min-1] 60 × π × (D1 + D2) × (D1 - D2) D1 : Max. Dia. of Workpiece [mm] Vc= π×Dm×n T1 = 4,000 × f × Vc D2 : Min. Dia. of Workpiece [mm] Vc : Cutting speed [m/min] Information Cutting Time (Cut-Off) T : Cutting Time [second] Technical T1 : Cutting Time before reaching • At Constant Revolution Max. Spindle Revolution [second] T= 60 × D1 T3 : Cutting Time when reaching (ID3) 2×f×n Max. Spindle Revolution [second] • At Constant Cutting Speed f : Feed Rate [mm/rev] ID1 60 × π × (D1 + D3) × (D1 - D3) n : Spindle Revolution [min-1] T1 = 4,000 × f × Vc nmax : Max. Spindle Revolution [min-1] D1 : Max. Dia. of Workpiece [mm] T3 = T1 + 60 × D3 D3 : Diameter when reaching 2 × f × nmax Max. Spindle Revolution [mm] Vc : Cutting speed [m/min] R33