Основной каталог Kyocera 2016-2017 - страница 954

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

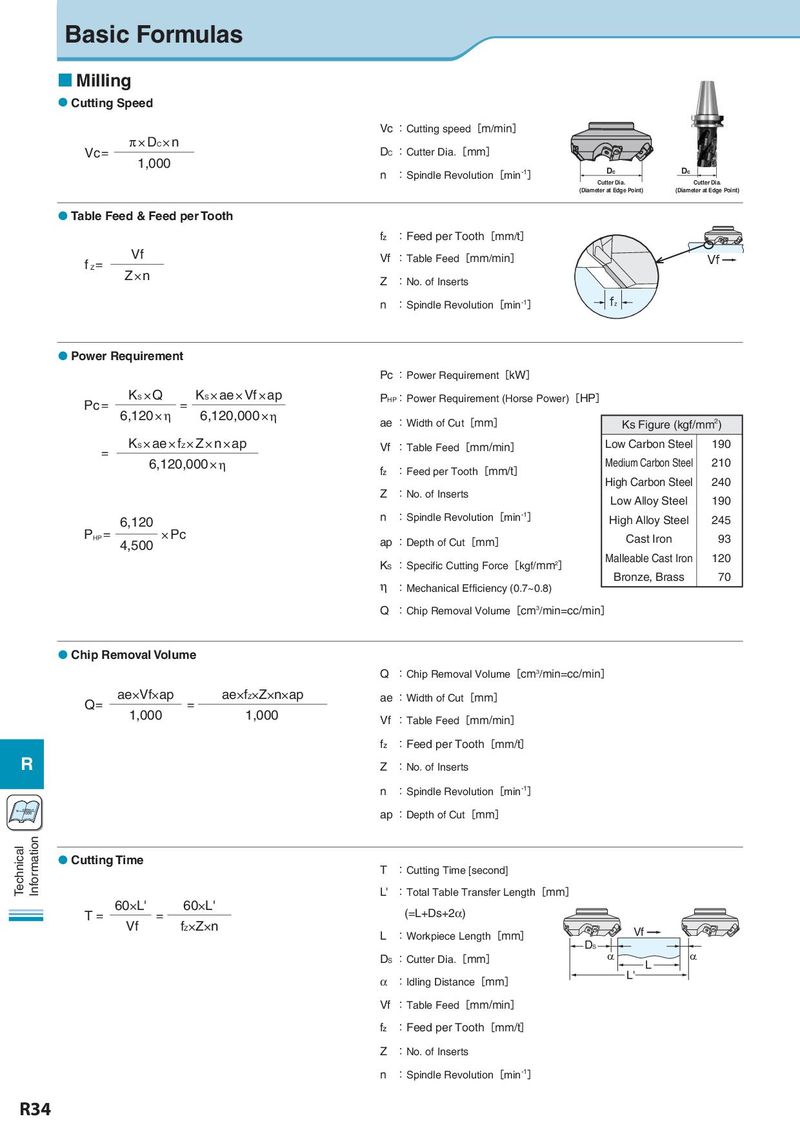

Basic Formulas Milling Cutting Speed Vc :Cutting speed[m/min] Vc = π × DC × n DC :Cutter Dia.[mm] 1,000 :Spindle Revolution[min-1] Dc Dc n Cutter Dia. Cutter Dia. (Diameter at Edge Point) (Diameter at Edge Point) Table Feed & Feed per Tooth fz :Feed per Tooth[mm/t] f Z= Vf Vf :Table Feed[mm/min] Vf Z×n Z :No. of Inserts n :Spindle Revolution[min-1] fz Power Requirement Pc :Power Requirement[kW] Pc = KS × Q = KS × ae × Vf × ap PHP:Power Requirement (Horse Power)[HP] 6,120 × η 6,120,000 × η ae :Width of Cut[mm] Ks Figure (kgf/mm2) = KS × ae × fZ × Z × n × ap Vf :Table Feed[mm/min] Low Carbon Steel 190 6,120,000 × η fz :Feed per Tooth[mm/t] Medium Carbon Steel 210 High Carbon Steel 240 Z :No. of Inserts Low Alloy Steel 190 6,120 n :Spindle Revolution[min-1] High Alloy Steel 245 PHP = 4,500 × Pc ap :Depth of Cut[mm] Cast Iron 93 KS :Specific Cutting Force[kgf/mm2] Malleable Cast Iron 120 η Bronze, Brass 70 :Mechanical Efficiency (0.7~0.8) Q :Chip Removal Volume[cm3/min=cc/min] Chip Removal Volume Q :Chip Removal Volume[cm3/min=cc/min] Q= ae×Vf×ap = ae×fZ×Z×n×ap ae :Width of Cut[mm] 1,000 1,000 Vf :Table Feed[mm/min] fz :Feed per Tooth[mm/t] R Z :No. of Inserts n :Spindle Revolution[min-1] Vc= π×Dm×n ap :Depth of Cut[mm] Technical Information Cutting Time T :Cutting Time [second] L' :Total Table Transfer Length[mm] T= 60×L' = 60×L' (=L+Ds+2α) Vf fZ×Z×n L :Workpiece Length[mm] Vf DS DS :Cutter Dia.[mm] D L D α :Idling Distance[mm] L' Vf :Table Feed[mm/min] fz :Feed per Tooth[mm/t] Z :No. of Inserts n :Spindle Revolution[min-1] R34