Основной каталог Kyocera 2016-2017 - страница 868

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

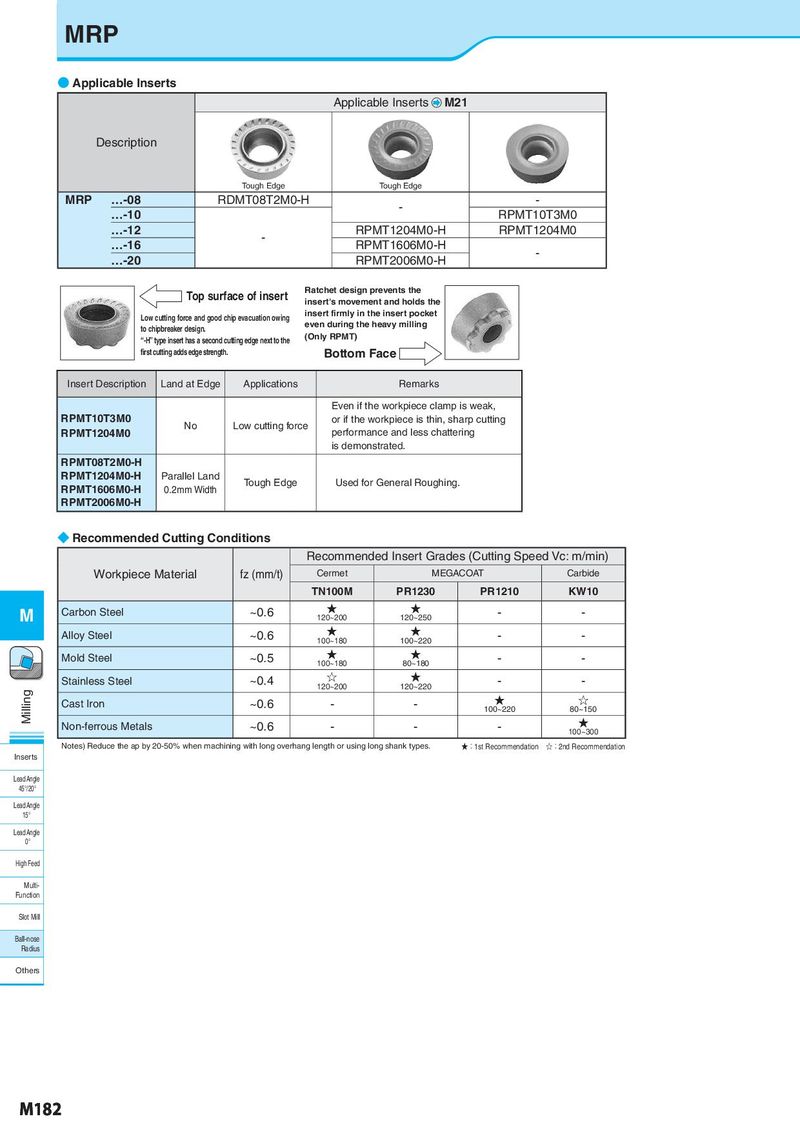

MRP ● Applicable Inserts Applicable Inserts M21 Description Tough Edge Tough Edge MRP …-08 RDMT08T2M0-H - - …-10 RPMT10T3M0 …-12 - RPMT1204M0-H RPMT1204M0 …-16 RPMT1606M0-H - …-20 RPMT2006M0-H Top surface of insert Ratchet design prevents the insert's movement and holds the Low cutting force and good chip evacuation owing insert firmly in the insert pocket to chipbreaker design. even during the heavy milling “-H” type insert has a second cutting edge next to the (Only RPMT) first cutting adds edge strength. Bottom Face Insert Description Land at Edge Applications Remarks Even if the workpiece clamp is weak, RPMT10T3M0 No Low cutting force or if the workpiece is thin, sharp cutting RPMT1204M0 performance and less chattering is demonstrated. RPMT08T2M0-H RPMT1204M0-H Parallel Land Tough Edge Used for General Roughing. RPMT1606M0-H 0.2mm Width RPMT2006M0-H ◆ Recommended Cutting Conditions Recommended Insert Grades (Cutting Speed Vc: m/min) Workpiece Material fz (mm/t) Cermet MEGACOAT Carbide TN100M PR1230 PR1210 KW10 M Carbon Steel ~0.6 ★ ★ - - 120~200 120~250 Alloy Steel ~0.6 ★ ★ - - 100~180 100~220 Mold Steel ~0.5 ★ ★ - - 100~180 80~180 Stainless Steel ~0.4 ☆ ★ - - Milling 120~200 120~220 Cast Iron ~0.6 - - ★ ☆ 100~220 80~150 Non-ferrous Metals ~0.6 - - - ★ 100~300 Notes) Reduce the ap by 20-50% when machining with long overhang length or using long shank types. ★:1st Recommendation ☆:2nd Recommendation Inserts Lead Angle 45°/20° Lead Angle 15° Lead Angle 0° High Feed Multi- Function Slot Mill Ball-nose Radius Others M182