Основной каталог Kyocera 2016-2017 - страница 858

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

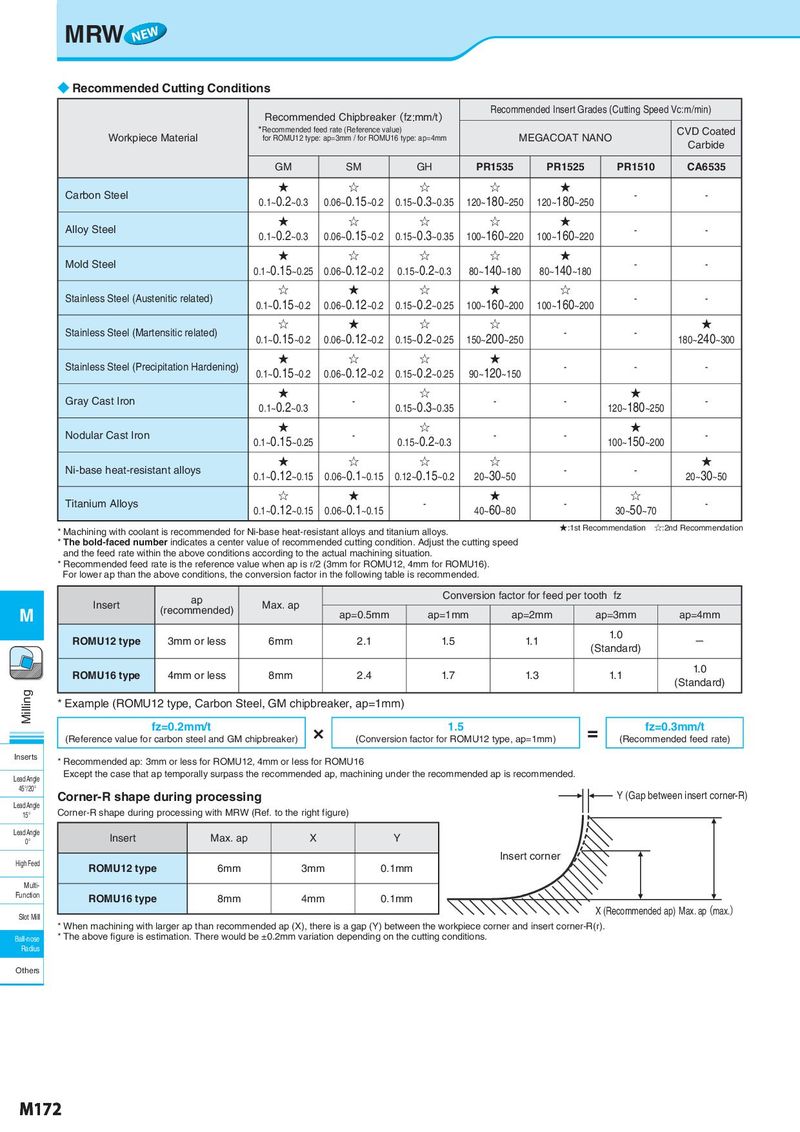

MRW NEW ◆ Recommended Cutting Conditions Recommended Chipbreaker(fz:mm/t) Recommended Insert Grades (Cutting Speed Vc:m/min) Workpiece Material *Recommended feed rate (Reference value) MEGACOAT NANO CVD Coated for ROMU12 type: ap=3mm / for ROMU16 type: ap=4mm Carbide GM SM GH PR1535 PR1525 PR1510 CA6535 Carbon Steel ★ ☆ ☆ ☆ ★ - - 0.1~0.2~0.3 0.06~0.15~0.2 0.15~0.3~0.35 120~180~250 120~180~250 Alloy Steel ★ ☆ ☆ ☆ ★ - - 0.1~0.2~0.3 0.06~0.15~0.2 0.15~0.3~0.35 100~160~220 100~160~220 Mold Steel ★ ☆ ☆ ☆ ★ - - 0.1~0.15~0.25 0.06~0.12~0.2 0.15~0.2~0.3 80~140~180 80~140~180 Stainless Steel (Austenitic related) ☆ ★ ☆ ★ ☆ - - 0.1~0.15~0.2 0.06~0.12~0.2 0.15~0.2~0.25 100~160~200 100~160~200 Stainless Steel (Martensitic related) ☆ ★ ☆ ☆ - - ★ 0.1~0.15~0.2 0.06~0.12~0.2 0.15~0.2~0.25 150~200~250 180~240~300 Stainless Steel (Precipitation Hardening) ★ ☆ ☆ ★ - - - 0.1~0.15~0.2 0.06~0.12~0.2 0.15~0.2~0.25 90~120~150 Gray Cast Iron ★ - ☆ - - ★ - 0.1~0.2~0.3 0.15~0.3~0.35 120~180~250 Nodular Cast Iron ★ - ☆ - - ★ - 0.1~0.15~0.25 0.15~0.2~0.3 100~150~200 Ni-base heat-resistant alloys ★ ☆ ☆ ☆ - - ★ 0.1~0.12~0.15 0.06~0.1~0.15 0.12~0.15~0.2 20~30~50 20~30~50 Titanium Alloys ☆ ★ - ★ - ☆ - 0.1~0.12~0.15 0.06~0.1~0.15 40~60~80 30~50~70 * Machining with coolant is recommended for Ni-base heat-resistant alloys and titanium alloys. ★:1st Recommendation ☆:2nd Recommendation * The bold-faced number indicates a center value of recommended cutting condition. Adjust the cutting speed and the feed rate within the above conditions according to the actual machining situation. * Recommended feed rate is the reference value when ap is r/2 (3mm for ROMU12, 4mm for ROMU16). For lower ap than the above conditions, the conversion factor in the following table is recommended. ap Conversion factor for feed per tooth fz M Insert (recommended) Max. ap ap=0.5mm ap=1mm ap=2mm ap=3mm ap=4mm ROMU12 type 3mm or less 6mm 2.1 1.5 1.1 1.0 - (Standard) ROMU16 type 4mm or less 8mm 2.4 1.7 1.3 1.1 1.0 (Standard) Milling * Example (ROMU12 type, Carbon Steel, GM chipbreaker, ap=1mm) fz=0.2mm/t × 1.5 = fz=0.3mm/t (Reference value for carbon steel and GM chipbreaker) (Conversion factor for ROMU12 type, ap=1mm) (Recommended feed rate) Inserts * Recommended ap: 3mm or less for ROMU12, 4mm or less for ROMU16 Lead Angle Except the case that ap temporally surpass the recommended ap, machining under the recommended ap is recommended. 45°/20° Corner-R shape during processing Y (Gap between insert corner-R) Lead Angle Corner-R shape during processing with MRW (Ref. to the right figure) 15° Lead Angle Insert Max. ap X Y 0° High Feed Insert corner ROMU12 type 6mm 3mm 0.1mm Multi- Function ROMU16 type 8mm 4mm 0.1mm Slot Mill X (Recommended ap) Max. ap(max.) * When machining with larger ap than recommended ap (X), there is a gap (Y) between the workpiece corner and insert corner-R(r). Ball-nose * The above figure is estimation. There would be ±0.2mm variation depending on the cutting conditions. Radius Others M172