Основной каталог Kyocera 2016-2017 - страница 815

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

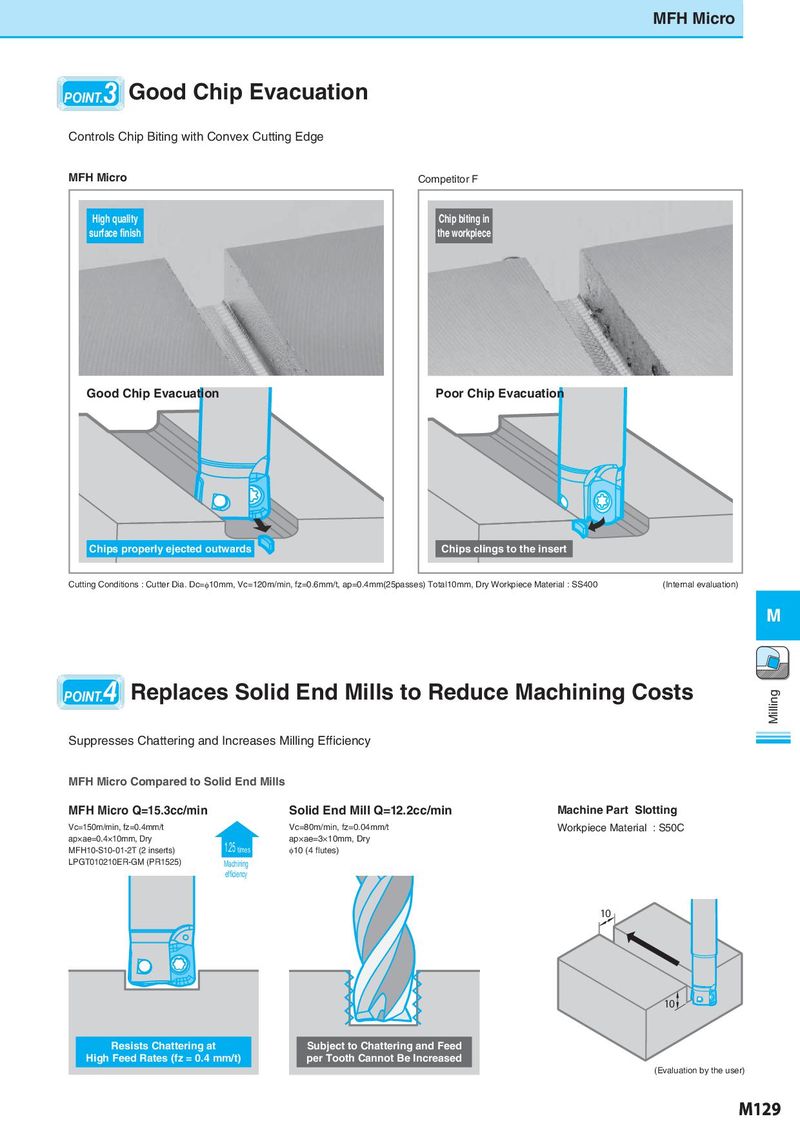

MFH Micro 3 POINT. Good Chip Evacuation Controls Chip Biting with Convex Cutting Edge MFH Micro Competitor F High quality Chip biting in surface finish the workpiece Good Chip Evacuation Poor Chip Evacuation Chips properly ejected outwards Chips clings to the insert Cutting Conditions : Cutter Dia. Dc=φ10mm, Vc=120m/min, fz=0.6mm/t, ap=0.4mm(25passes) Total10mm, Dry Workpiece Material : SS400 (Internal evaluation) M 4 POINT. Replaces Solid End Mills to Reduce Machining Costs Milling Suppresses Chattering and Increases Milling Efficiency MFH Micro Compared to Solid End Mills MFH Micro Q=15.3cc/min Solid End Mill Q=12.2cc/min Machine Part Slotting Vc=150m/min, fz=0.4mm/t Vc=80m/min, fz=0.04mm/t Workpiece Material : S50C ap×ae=0.4×10mm, Dry 1.25 times ap×ae=3×10mm, Dry MFH10-S10-01-2T (2 inserts) φ10 (4 flutes) LPGT010210ER-GM (PR1525) Machining efficiency 10 10 Resists Chattering at Subject to Chattering and Feed High Feed Rates (fz = 0.4 mm/t) per Tooth Cannot Be Increased (Evaluation by the user) M129