Основной каталог Kyocera 2016-2017 - страница 814

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

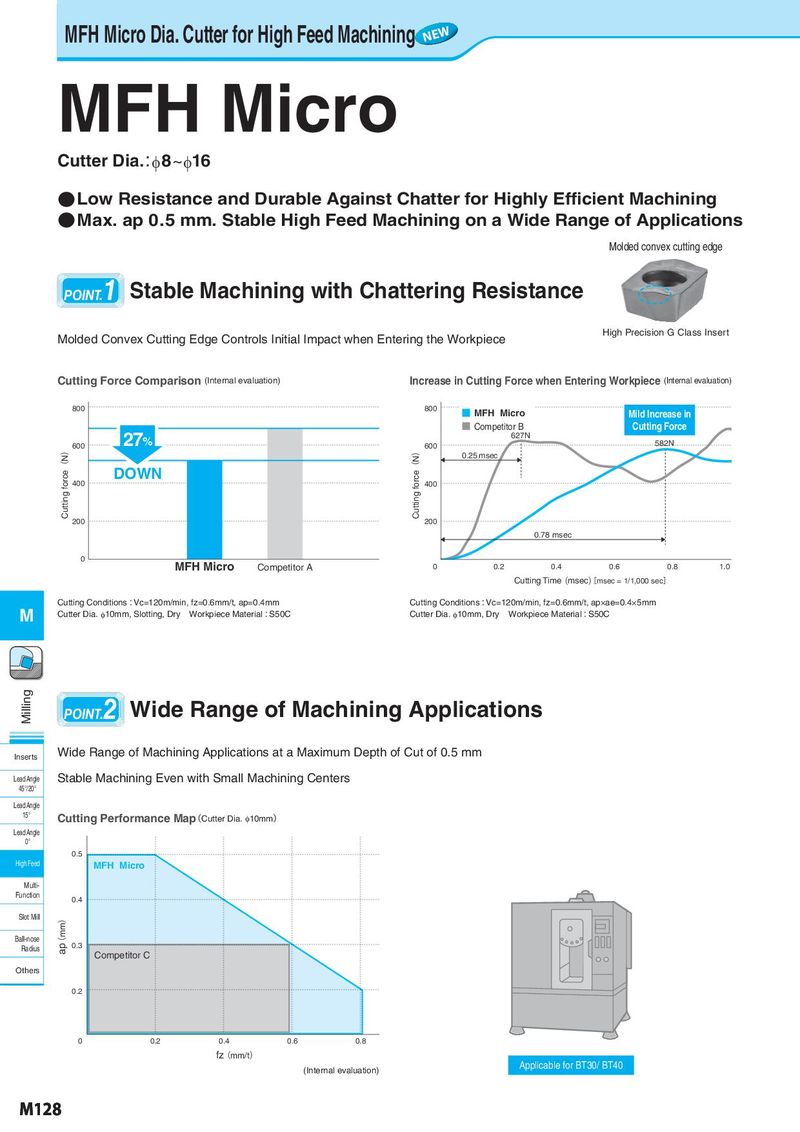

MFH Micro Dia. Cutter for High Feed Machining NEW MFH Micro Cutter Dia: . φ8~φ16 ● Low Resistance and Durable Against Chatter for Highly Efficient Machining ● Max. ap 0.5 mm. Stable High Feed Machining on a Wide Range of Applications Molded convex cutting edge 1 POINT. Stable Machining with Chattering Resistance Molded Convex Cutting Edge Controls Initial Impact when Entering the Workpiece High Precision G Class Insert Cutting Force Comparison (Internal evaluation) Increase in Cutting Force when Entering Workpiece (Internal evaluation) 800 800 MFH Micro Mild Increase in Competitor B Cutting Force 27% 627N Cutting force(N) 600 Cutting force(N) 600 582N 0.25 msec 400 DOWN 400 200 200 0.78 msec 0 MFH Micro Competitor A 0 0.2 0.4 0.6 0.8 1.0 Cutting Time(msec)[msec = 1/1,000 sec] Cutting Conditions:Vc=120m/min, fz=0.6mm/t, ap=0.4mm Cutting Conditions:Vc=120m/min, fz=0.6mm/t, ap×ae=0.4×5mm M Cutter Dia. φ10mm, Slotting, Dry Workpiece Material:S50C Cutter Dia. φ10mm, Dry Workpiece Material:S50C Milling 2 POINT. Wide Range of Machining Applications Inserts Wide Range of Machining Applications at a Maximum Depth of Cut of 0.5 mm Lead Angle Stable Machining Even with Small Machining Centers 45°/20° Lead Angle 15° Cutting Performance Map(Cutter Dia. φ10mm) Lead Angle 0° 0.5 High Feed MFH Micro Multi- Function 0.4 Slot Mill ap(mm) Ball-nose 0.3 Radius Competitor C Others 0.2 0 0.2 0.4 0.6 0.8 fz(mm/t) Applicable for BT30/ BT40 (Internal evaluation) M128