Основной каталог Kyocera 2016-2017 - страница 794

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

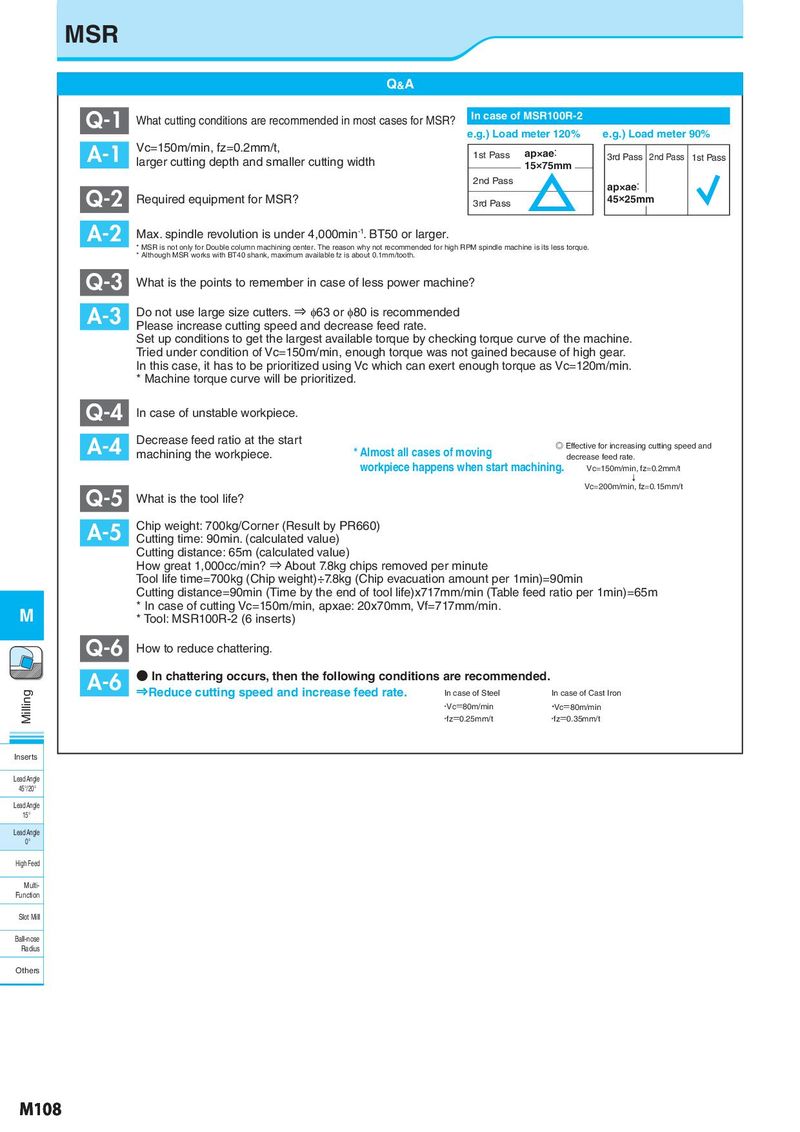

MSR Q&A Q-1 What cutting conditions are recommended in most cases for MSR? In case of MSR100R-2 e.g.) Load meter 120% e.g.) Load meter 90% A-1 Vc=150m/min, fz=0.2mm/t, 1st Pass ap×ae: 3rd Pass 2nd Pass 1st Pass larger cutting depth and smaller cutting width 15×75mm 2nd Pass ap×ae: Q-2 Required equipment for MSR? 3rd Pass 45×25mm A-2 Max. spindle revolution is under 4,000min-1. BT50 or larger. * MSR is not only for Double column machining center. The reason why not recommended for high RPM spindle machine is its less torque. * Although MSR works with BT40 shank, maximum available fz is about 0.1mm/tooth. Q-3 What is the points to remember in case of less power machine? A-3 Do not use large size cutters. ⇒ φ63 or φ80 is recommended Please increase cutting speed and decrease feed rate. Set up conditions to get the largest available torque by checking torque curve of the machine. Tried under condition of Vc=150m/min, enough torque was not gained because of high gear. In this case, it has to be prioritized using Vc which can exert enough torque as Vc=120m/min. * Machine torque curve will be prioritized. Q-4 In case of unstable workpiece. A-4 Decrease feed ratio at the start ◎ Effective for increasing cutting speed and machining the workpiece. *Almost all cases of moving decrease feed rate. workpiece happens when start machining. Vc=150m/min, fz=0.2mm/t ↓ Q-5 Vc=200m/min, fz=0.15mm/t What is the tool life? A-5 Chip weight: 700kg/Corner (Result by PR660) Cutting time: 90min. (calculated value) Cutting distance: 65m (calculated value) How great 1,000cc/min? ⇒ About 7.8kg chips removed per minute Tool life time=700kg (Chip weight)÷7.8kg (Chip evacuation amount per 1min)=90min Cutting distance=90min (Time by the end of tool life)x717mm/min (Table feed ratio per 1min)=65m M * In case of cutting Vc=150m/min, apxae: 20x70mm, Vf=717mm/min. * Tool: MSR100R-2 (6 inserts) Q-6 How to reduce chattering. A-6 ● In chattering occurs, then the following conditions are recommended. Milling ⇒Reduce cutting speed and increase feed rate. In case of Steel In case of Cast Iron ・Vc=80m/min ・Vc=80m/min ・fz=0.25mm/t ・fz=0.35mm/t Inserts Lead Angle 45°/20° Lead Angle 15° Lead Angle 0° High Feed Multi- Function Slot Mill Ball-nose Radius Others M108