Основной каталог Kyocera 2016-2017 - страница 795

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

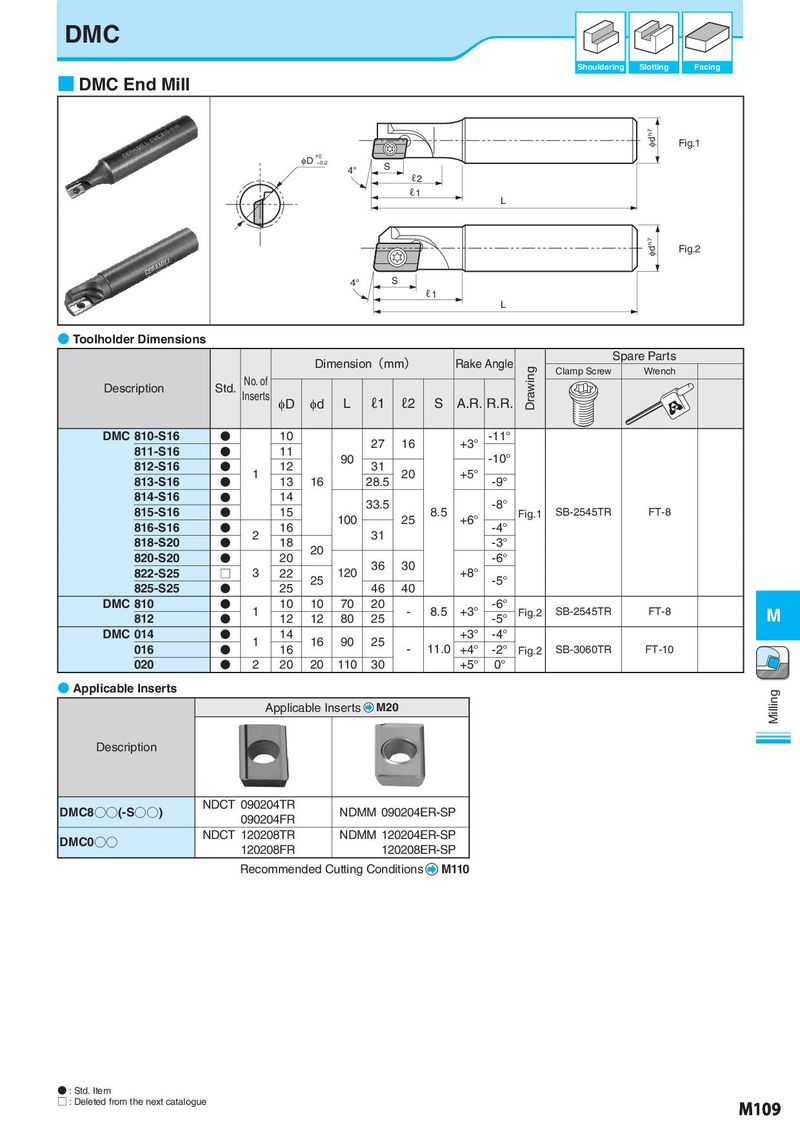

DMC Shouldering Slotting Facing ■ DMC End Mill φd h7 Fig.1 φD +0 −0.2 S 4° ℓ2 ℓ1 L φd h7 Fig.2 4° S ℓ1 L ● Toolholder Dimensions Dimension(mm) Rake Angle Spare Parts Drawing Clamp Screw Wrench Description Std. No. of Inserts φD φd L ℓ1 ℓ2 S A.R. R.R. DMC 810-S16 ● 10 27 16 +3° -11° 811-S16 ● 11 90 -10° 812-S16 ● 1 12 31 20 +5° 813-S16 ● 13 16 28.5 -9° 814-S16 ● 14 33.5 -8° 815-S16 ● 15 100 25 8.5 +6° Fig.1 SB-2545TR FT-8 816-S16 ● 2 16 31 -4° 818-S20 ● 18 20 -3° 820-S20 ● 20 36 30 -6° 822-S25 □ 3 22 25 120 +8° -5° 825-S25 ● 25 46 40 DMC 810 ● 1 10 10 70 20 - 8.5 +3° -6° Fig.2 SB-2545TR FT-8 M 812 ● 12 12 80 25 -5° DMC 014 ● 1 14 16 90 25 +3° -4° 016 ● 16 - 11.0 +4° -2° Fig.2 SB-3060TR FT-10 020 ● 2 20 20 110 30 +5° 0° ● Applicable Inserts Milling Applicable Inserts M20 Description DMC8○○(-S○○) NDCT 090204TR NDMM 090204ER-SP 090204FR DMC0○○ NDCT 120208TR NDMM 120204ER-SP 120208FR 120208ER-SP Recommended Cutting Conditions M110 ● : Std. Item □ : Deleted from the next catalogue M109