Основной каталог Kyocera 2016-2017 - страница 780

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

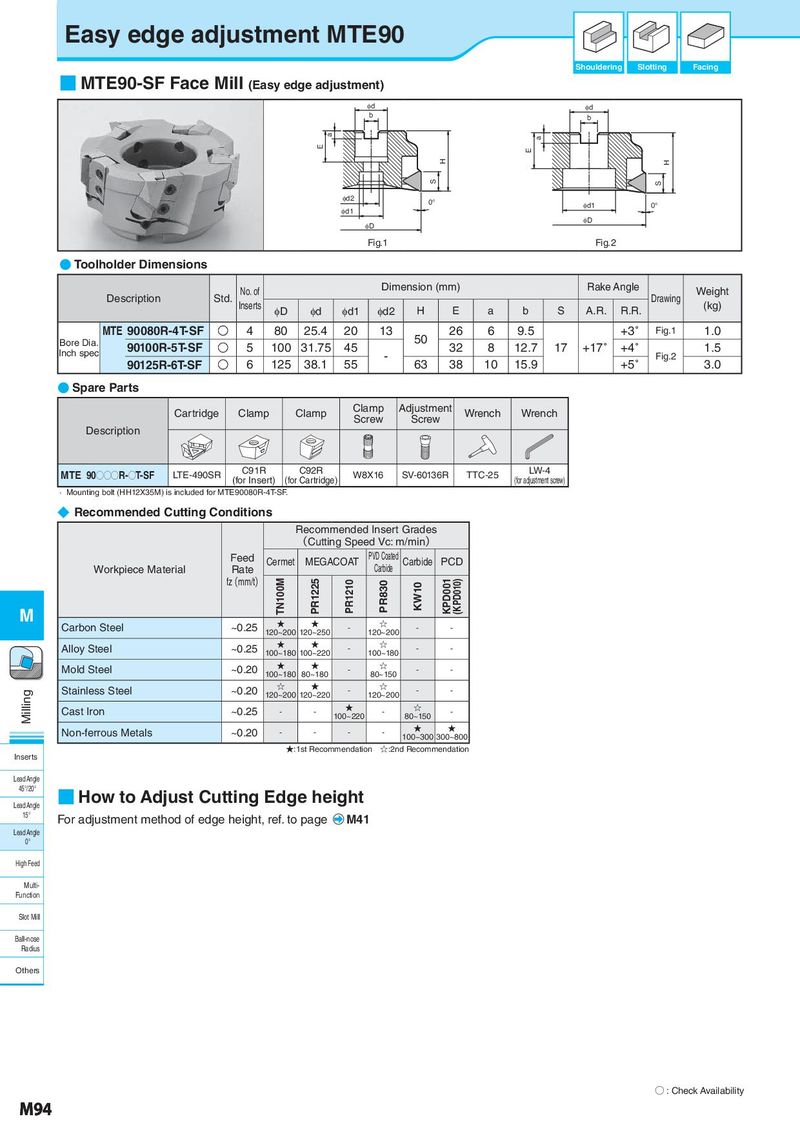

Easy edge adjustment MTE90 Shouldering Slotting Facing ■ MTE90-SF Face Mill (Easy edge adjustment) φd φd φd φd b b b b a a a a E E E E H H H H S S S S φd2 φd2 0° 0° φd1 0° φd1 φd1 0° φd1 φD φD φD φD Fig.1 Fig.2 ● Toolholder Dimensions No. of Dimension (mm) Rake Angle Weight Description Std. Inserts Drawing (kg) φD φd φd1 φd2 H E a b S A.R. R.R. MTE 90080R-4T-SF O 4 80 25.4 20 13 50 26 6 9.5 +3゚ Fig.1 1.0 Bore Dia. 90100R-5T-SF O 5 100 31.75 45 32 8 12.7 17 +17゚ +4゚ 1.5 Inch spec - Fig.2 90125R-6T-SF O 6 125 38.1 55 63 38 10 15.9 +5゚ 3.0 ● Spare Parts Cartridge Clamp Clamp Clamp Adjustment Wrench Wrench Screw Screw Description MTE 90OOOR-OT-SF LTE-490SR C91R C92R W8X16 SV-60136R TTC-25 LW-4 (for Insert) (for Cartridge) (for adjustment screw) · Mounting bolt (HH12X35M) is included for MTE90080R-4T-SF. ◆ Recommended Cutting Conditions Recommended Insert Grades (Cutting Speed Vc: m/min) Feed Cermet MEGACOAT PVD Coated Carbide PCD Workpiece Material Rate Carbide fz(mm/t) TN100M PR1225 PR1210 PR830 KW10 KPD001 (KPD010) M Carbon Steel ~0.25 ★ ★ ☆ 120~200 120~250 - 120~200 - - Alloy Steel ~0.25 ★ ★ - ☆ - - 100~180 100~220 100~180 Mold Steel ~0.20 ★ ★ - ☆ - - 100~180 80~180 80~150 Milling Stainless Steel ~0.20 ☆ ★ - ☆ - - 120~200 120~220 120~200 Cast Iron ~0.25 - - ★ - ☆ - 100~220 80~150 Non-ferrous Metals ~0.20 - - - - ★ ★ 100~300 300~800 ★:1st Recommendation ☆:2nd Recommendation Inserts Lead Angle 45°/20° ■ How to Adjust Cutting Edge height Lead Angle 15° For adjustment method of edge height, ref. to page M41 Lead Angle 0° High Feed Multi- Function Slot Mill Ball-nose Radius Others ○ : Check Availability M94