Основной каталог Kyocera 2016-2017 - страница 779

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

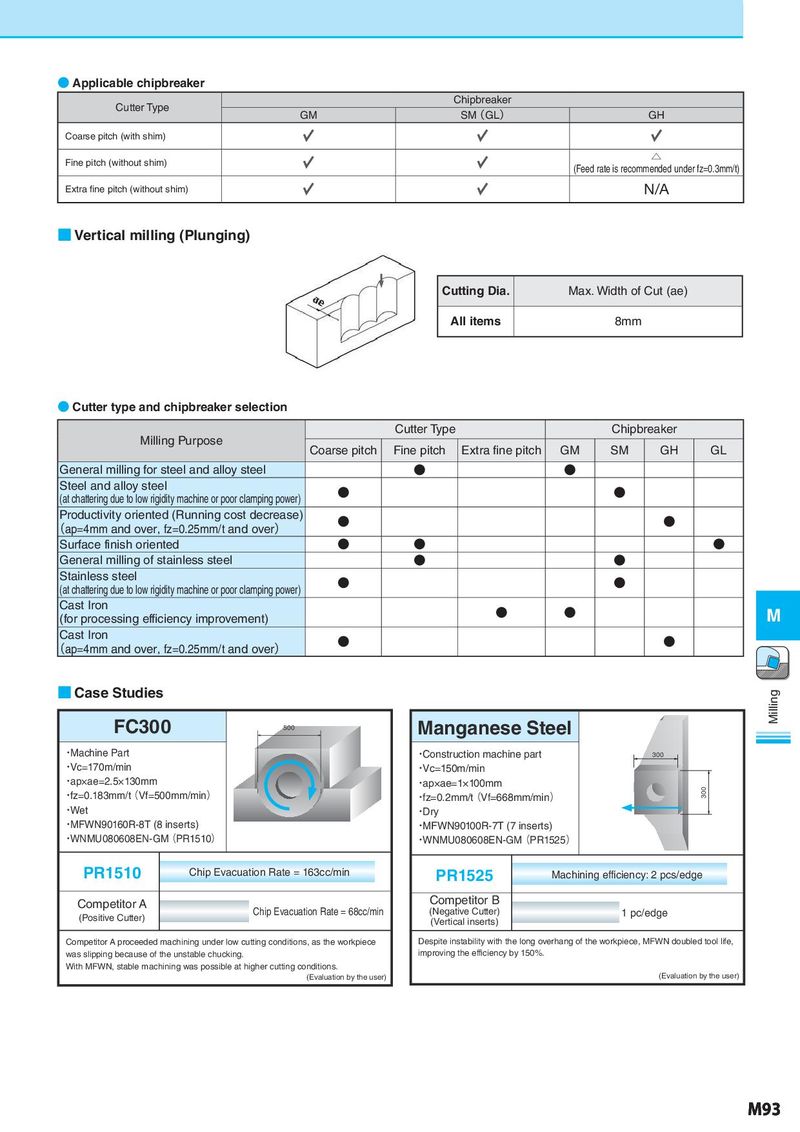

● Applicable chipbreaker Cutter Type Chipbreaker GM SM(GL) GH Coarse pitch (with shim) Fine pitch (without shim) △ (Feed rate is recommended under fz=0.3mm/t) Extra fine pitch (without shim) N/A ■ Vertical milling (Plunging) Cutting Dia. Max. Width of Cut (ae) All items 8mm ● Cutter type and chipbreaker selection Cutter Type Chipbreaker Milling Purpose Coarse pitch Fine pitch Extra fine pitch GM SM GH GL General milling for steel and alloy steel ● ● Steel and alloy steel ● ● (at chattering due to low rigidity machine or poor clamping power) Productivity oriented (Running cost decrease) ● ● (ap=4mm and over, fz=0.25mm/t and over) Surface finish oriented ● ● ● General milling of stainless steel ● ● Stainless steel ● ● (at chattering due to low rigidity machine or poor clamping power) Cast Iron ● ● M (for processing efficiency improvement) Cast Iron ● ● (ap=4mm and over, fz=0.25mm/t and over) ■ Case Studies Milling FC300 500 Manganese Steel ・Machine Part ・Construction machine part 300 ・Vc=170m/min ・Vc=150m/min ・ap×ae=2.5×130mm ・ap×ae=1×100mm ・fz=0.183mm/t(Vf=500mm/min) ・fz=0.2mm/t(Vf=668mm/min) 300 ・Wet ・Dry ・MFWN90160R-8T (8 inserts) ・MFWN90100R-7T (7 inserts) ・WNMU080608EN-GM(PR1510) ・WNMU080608EN-GM(PR1525) PR1510 Chip Evacuation Rate = 163cc/min PR1525 Machining efficiency: 2 pcs/edge Competitor A Competitor B (Positive Cutter) Chip Evacuation Rate = 68cc/min (Negative Cutter) 1 pc/edge (Vertical inserts) Competitor A proceeded machining under low cutting conditions, as the workpiece Despite instability with the long overhang of the workpiece, MFWN doubled tool life, was slipping because of the unstable chucking. improving the efficiency by 150%. With MFWN, stable machining was possible at higher cutting conditions. (Evaluation by the user) (Evaluation by the user) M93