Основной каталог Kyocera 2016-2017 - страница 747

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

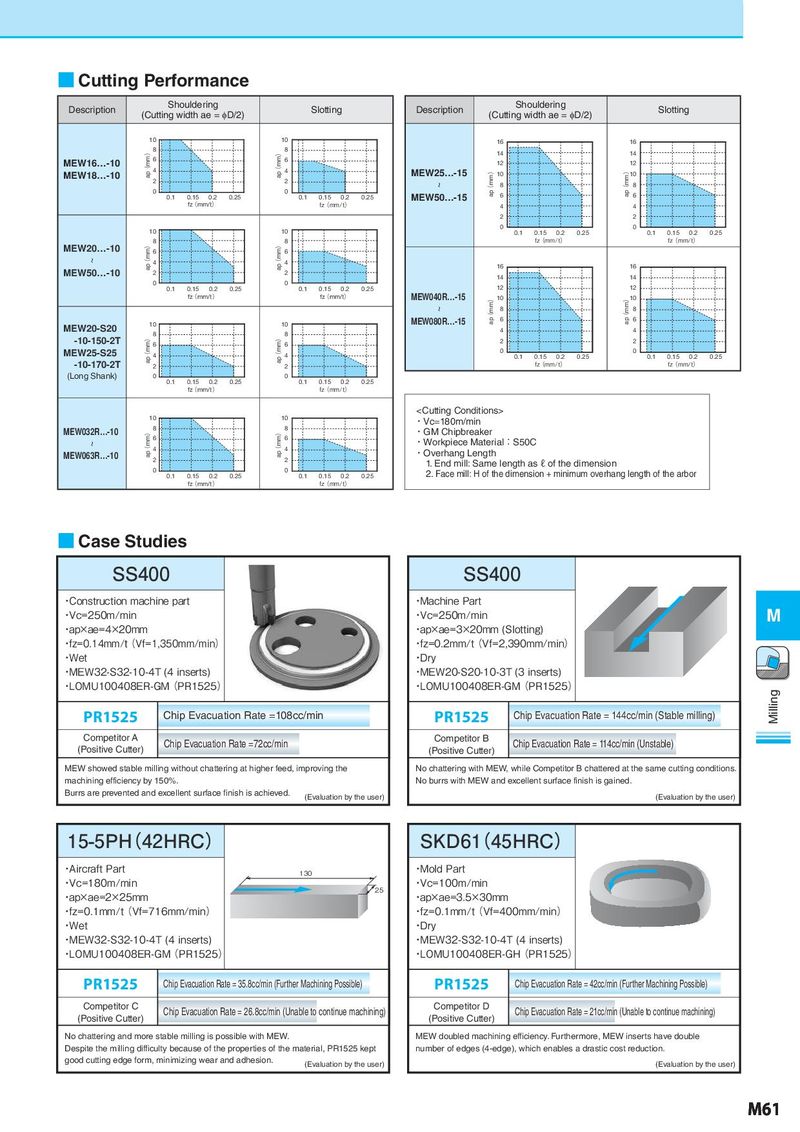

■ Cutting Performance

Description Shouldering Slotting Description Shouldering Slotting

(Cutting width ae = φD/2) (Cutting width ae = φD/2)

MEW16…-10 ap(mm)a1p(084620aaa111mppp(((084620846208462000mmmm0)mmm.1000)))...111a pa pa( p(m(mmmm)m)) ap(mm)a1p(084620aaa111pm(pp((846200008462084620mmmmm0)mmmm.10)000)))....1111a pa pa( p(m(mmmm)m)) a1111p(a024684620aaa1111p(111111111111ppp( ( (m024684620024602460246846208462084620mmmmmm0)mmm.0)1000) ) )....1111 a1111p(aaaa0246846201111p(111111111111ppp( ( (m024684620846208462084620024602460246mmmmm0)mmm.0)1000) ) ).1...111

MEW18…-10 MEW25…-15 ap(mm)apapaa(pp(m((mmmmm)mm))) apapaaa(ppp(m(((mmmmmm)mmm))))

~

0fz.( 1000fff5zzz.m..(((111555mmmmt/0mmm).2t/tt//000)))...222 0.20005...222555 0fz . (10f000fffz5zzz....(m(((11115555mmmmm/mt0mmm.)/2///t0t t t000.)...) ) )2222 0.200005....22225555 MEW50…-15

ap(mm)a1p(084620aaa111mppp(((084620846208462000mmmm0)mmm.1000)))...111a pa pa( p(m(mmmm)m)) ap(mm)a1p(084620aaa111pm(pp((846200846208462000mmmmm0)mmmm.10)000)))....1111a pa pa( p(m(mmmm)m)) 0f z .(0f1000fffz.zzz5(...1( ( (m1115555mmmmmm/mmmt0/.)t0///2t t t000.)...2) ) )222 0.02000.5...22225555 0f z .0f(1000zfff.(zzz51...( ( (m1115m555mmmm/mmmt0/t0.)///2t t t000.)2...) ) )222 00.2000.25...2225555

MEW20…-10

~ a1111p(a024684620aaa1111p(111111111111ppp( ( (m846200246024602460246846208462084620mmmmmm0)mmm.0)1000) ) )....1111 a1111p(aaaa8462002461111p(111111111111ppp( ( (m024684620846208462084620024602460246mmmmm0)mmm.0)1000) ) ).1...111

MEW50…-10

0fz.( 1000fff5zzz.m..(((111555mmmmt/0mmm).2t/tt//000)))...222 0.20005...222555 0fz. ( 10000ffff5z.zzz...(m(((11115555mmmmmt/m0mmm).t/2t t t///0000).) ) )...2222 0.200005....22225555 MEW040R…-15 ap(mm)apapa(app(m((mmmmm)mm))) apaapa(appp(m(((mmmmmm)mmm))))

a1p(084620aaa111mppp(((084620846200846200mmmm0)mmm.1000)))...111 a1p(084620aaa111pm(pp((846200084620846200mmmmm0)mmmm.10)000)))....1111 ~

MEW20-S20 MEW080R…-15

-10-150-2T ap(mm) apapa(ap(pm((mmmmm)mm))) ap(mm) apapa(ap(pm((mmmmm)mm)))

MEW25-S25 0f z .(0f1000fffz.zzz5(...1( ( (m1115555mmmmmm/mmmt0/.)t0///2t t t000.)...2) ) )222 0.02000.5...22225555 0f z .0f(1000zfff.(zzz51...( ( (m1115m555mmmm/mmmt0/t0.)///2t t t000.)2...) ) )222 00.2000.25...2225555

-10-170-2T

(Long Shank) 0fz.( 1000fff5zzz.m..(((111555mmmmt/0mmm).2t/tt//000)))...222 0.20005...222555 0fz . (10f000fffz5zzz....(m(((11115555mmmmm/mt0mmm.)/2///t0t t t000.)...) ) )2222 0.200005....22225555

a1p(084620aaa111mppp(((84620002084620846200mmmm0)mmm.10000)))....1111 a1p(084620aaa111pm(pp((84620020846208462000mmmmm0)mmmm.10)000)))....1111