Основной каталог Kyocera 2016-2017 - страница 738

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

MEW

■ MEW

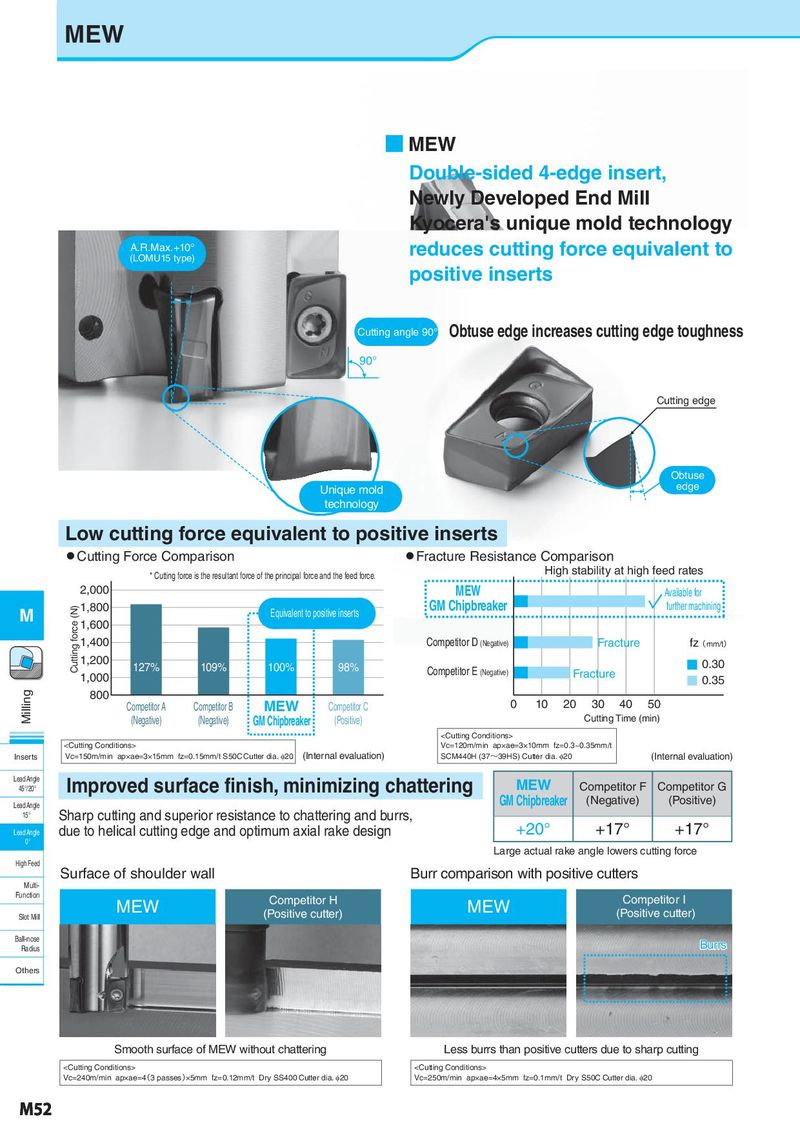

Double-sided 4-edge insert,

Newly Developed End Mill

Kyocera's unique mold technology

A.R.Max.+10° reduces cutting force equivalent to

(LOMU15 type)

positive inserts

Cutting angle 90° Obtuse edge increases cutting edge toughness

90°

Cutting edge

Obtuse

Unique mold edge

technology

Low cutting force equivalent to positive inserts

● Cutting Force Comparison ● Fracture Resistance Comparison

* Cutting force is the resultant force of the principal force and the feed force. High stability at high feed rates

2,000 MEW Available for

M Cutting force (N) 1,800 Equivalent to positive inserts GM Chipbreaker further machining

1,600

1,400 Competitor D (Negative) Fracture fz(mm/t)

1,200 127% 109% 100% 98% 0.30

1,000 Competitor E (Negative) Fracture 0.35

Milling 800 MEW 0 10 20 30 40 50

Competitor A Competitor B Competitor C

(Negative) (Negative) GM Chipbreaker (Positive) Cutting Time (min)