Основной каталог Kyocera 2016-2017 - страница 739

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

Shouldering Slotting Facing Vertical

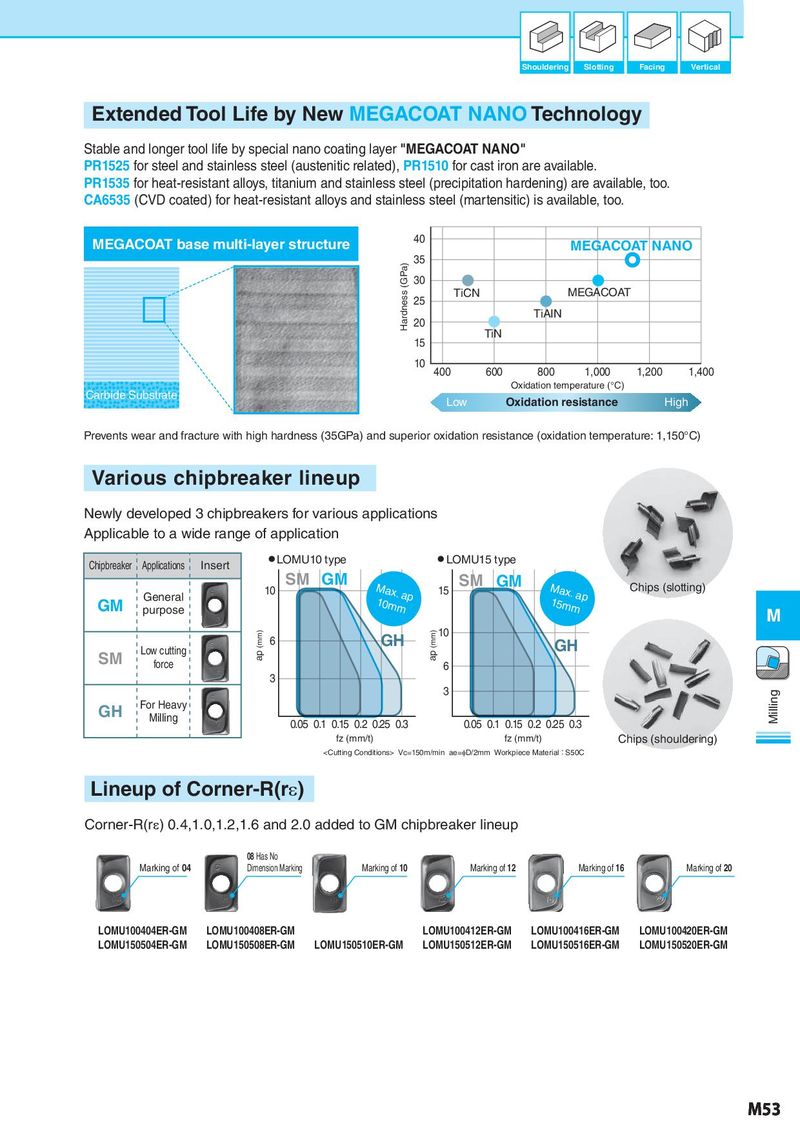

Extended Tool Life by New MEGACOAT NANO Technology

Stable and longer tool life by special nano coating layer "MEGACOAT NANO"

PR1525 for steel and stainless steel (austenitic related), PR1510 for cast iron are available.

PR1535 for heat-resistant alloys, titanium and stainless steel (precipitation hardening) are available, too.

CA6535 (CVD coated) for heat-resistant alloys and stainless steel (martensitic) is available, too.

MEGACOAT base multi-layer structure 40 MEGACOAT NANO

Hardness (GPa) 35

30

25 TiCN MEGACOAT

20 TiAIN

15 TiN

10 400 600 800 1,000 1,200 1,400

Oxidation temperature (°C)

Carbide Substrate Low Oxidation resistance High

Prevents wear and fracture with high hardness (35GPa) and superior oxidation resistance (oxidation temperature: 1,150°C)

Various chipbreaker lineup

Newly developed 3 chipbreakers for various applications

Applicable to a wide range of application

Chipbreaker Applications Insert ● LOMU10 type ● LOMU15 type

10 SM GM M10amx.map 15 SM GM M15amx.map Chips (slotting)

GM General

purpose M

(mm) 6 GH (mm) 10

SM Low cutting ap ap GH

force 6

3

3 Milling

GH For Heavy

Milling 0.05 0.1 0.15 0.2 0.25 0.3 0.05 0.1 0.15 0.2 0.25 0.3

fz (mm/t) fz (mm/t) Chips (shouldering)