Основной каталог Kyocera 2016-2017 - страница 728

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

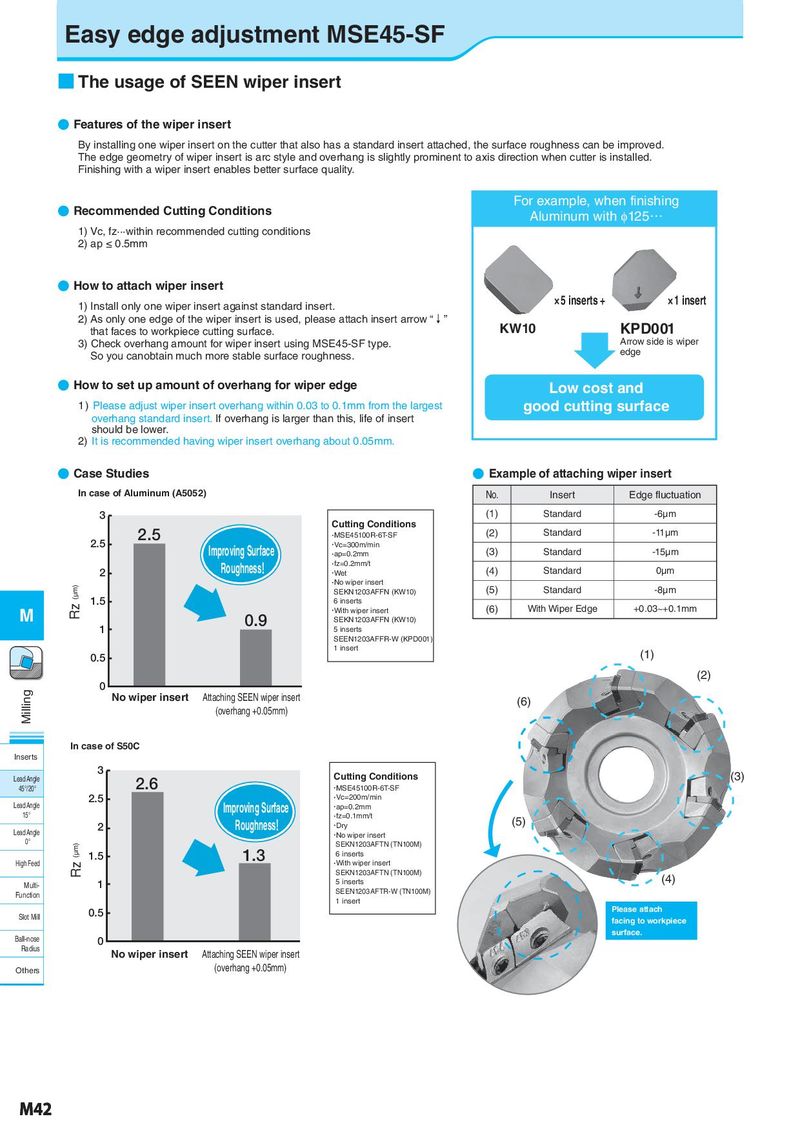

Easy edge adjustment MSE45-SF ■ The usage of SEEN wiper insert ● Features of the wiper insert By installing one wiper insert on the cutter that also has a standard insert attached, the surface roughness can be improved. The edge geometry of wiper insert is arc style and overhang is slightly prominent to axis direction when cutter is installed. Finishing with a wiper insert enables better surface quality. ● Recommended Cutting Conditions For example, when finishing Aluminum with φ125… 1) Vc, fz···within recommended cutting conditions 2) ap ≤ 0.5mm ● How to attach wiper insert 1) Install only one wiper insert against standard insert. × 5 inserts + × 1 insert 2) As only one edge of the wiper insert is used, please attach insert arrow “↓” KW10 KPD001 that faces to workpiece cutting surface. 3) Check overhang amount for wiper insert using MSE45-SF type. Arrow side is wiper So you canobtain much more stable surface roughness. edge ● How to set up amount of overhang for wiper edge Low cost and 1) Please adjust wiper insert overhang within 0.03 to 0.1mm from the largest good cutting surface overhang standard insert. If overhang is larger than this, life of insert should be lower. 2) It is recommended having wiper insert overhang about 0.05mm. ● Case Studies ● Example of attaching wiper insert In case of Aluminum (A5052) No. Insert Edge fluctuation 3 (1) Standard -6μm 2.5 Cutting Conditions (2) ・MSE45100R-6T-SF Standard -11μm 2.5 Improving Surface ・Vc=300m/min (3) Standard -15μm ・ap=0.2mm Roughness! ・fz=0.2mm/t (4) Standard 0μm 2 ・Wet Rz (µm) ・No wiper insert (5) SEKN1203AFFN (KW10) Standard -8μm 1.5 6 inserts M ・With wiper insert (6) With Wiper Edge +0.03~+0.1mm 0.9 SEKN1203AFFN (KW10) 1 5 inserts SEEN1203AFFR-W (KPD001) 1 insert (1) 0.5 (2) Milling 0 No wiper insert Attaching SEEN wiper insert (6) (overhang +0.05mm) In case of S50C Inserts 3 Cutting Conditions (3) Lead Angle 2.6 45°/20° ・MSE45100R-6T-SF 2.5 ・Vc=200m/min Lead Angle Improving Surface ・ap=0.2mm 15° ・fz=0.1mm/t (5) Lead Angle 2 Roughness! ・Dry 0° ・No wiper insert Rz (µm) SEKN1203AFTN (TN100M) 1.5 1.3 6 inserts High Feed ・With wiper insert SEKN1203AFTN (TN100M) (4) Multi- 1 5 inserts Function SEEN1203AFTR-W (TN100M) 1 insert 0.5 Please attach Slot Mill facing to workpiece Ball-nose surface. Radius 0 No wiper insert Attaching SEEN wiper insert Others (overhang +0.05mm) M42