Основной каталог Kyocera 2016-2017 - страница 693

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

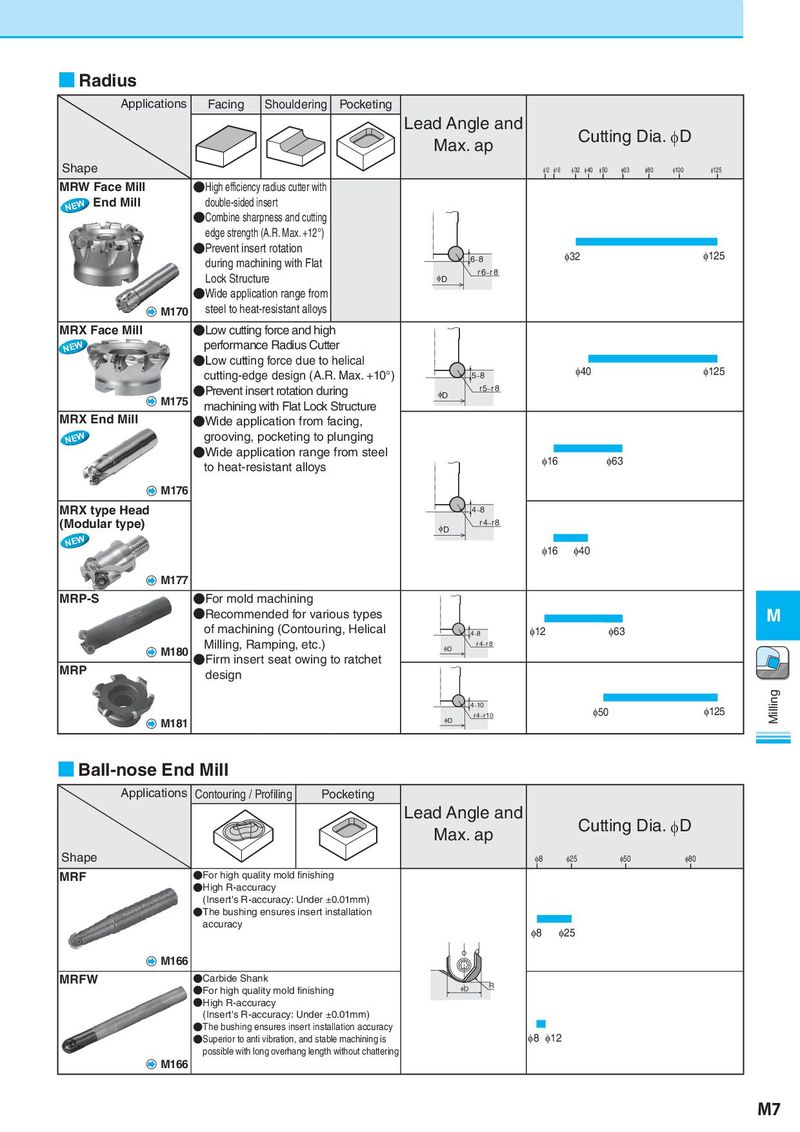

■ Radius Applications Facing Shouldering Pocketing Lead Angle and Cutting Dia. φD Max. ap Shape φ12 φ16 φ32 φ40 φ50 φ63 φ80 φ100 φ125 MRW Face Mill ●High efficiency radius cutter with NE W End Mill double-sided insert ●Combine sharpness and cutting edge strength (A.R. Max. +12°) ●Prevent insert rotation φ32 φ125 during machining with Flat 6~8 Lock Structure φD r 6~r 8 ●Wide application range from M170 steel to heat-resistant alloys MRX Face Mill ●Low cutting force and high NEW performance Radius Cutter ●Low cutting force due to helical cutting-edge design (A.R. Max. +10°) 5~8 φ40 φ125 ●Prevent insert rotation during φD r 5~r 8 M175 machining with Flat Lock Structure MRX End Mill ●Wide application from facing, NEW grooving, pocketing to plunging ●Wide application range from steel φ16 φ63 to heat-resistant alloys M176 MRX type Head 4~8 (Modular type) ID r 4~r 8 NEW φ16 φ40 M177 MRP-S ●For mold machining ●Recommended for various types M of machining (Contouring, Helical 4~8 φ12 φ63 Milling, Ramping, etc.) ID r 4~r 8 M180 ●Firm insert seat owing to ratchet MRP design 4~10 φ50 φ125 Milling ID r 4~r 10 M181 ■ Ball-nose End Mill Applications Contouring / Profiling Pocketing Lead Angle and Cutting Dia. φD Max. ap Shape φ8 φ25 φ50 φ80 MRF ●For high quality mold finishing ●High R-accuracy (Insert's R-accuracy: Under ±0.01mm) ●The bushing ensures insert installation accuracy φ8 φ25 M166 MRFW ●Carbide Shank ●For high quality mold finishing ID R ●High R-accuracy (Insert's R-accuracy: Under ±0.01mm) ●The bushing ensures insert installation accuracy ●Superior to anti vibration, and stable machining is φ8 φ12 possible with long overhang length without chattering M166 M7