Основной каталог Kyocera 2016-2017 - страница 689

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

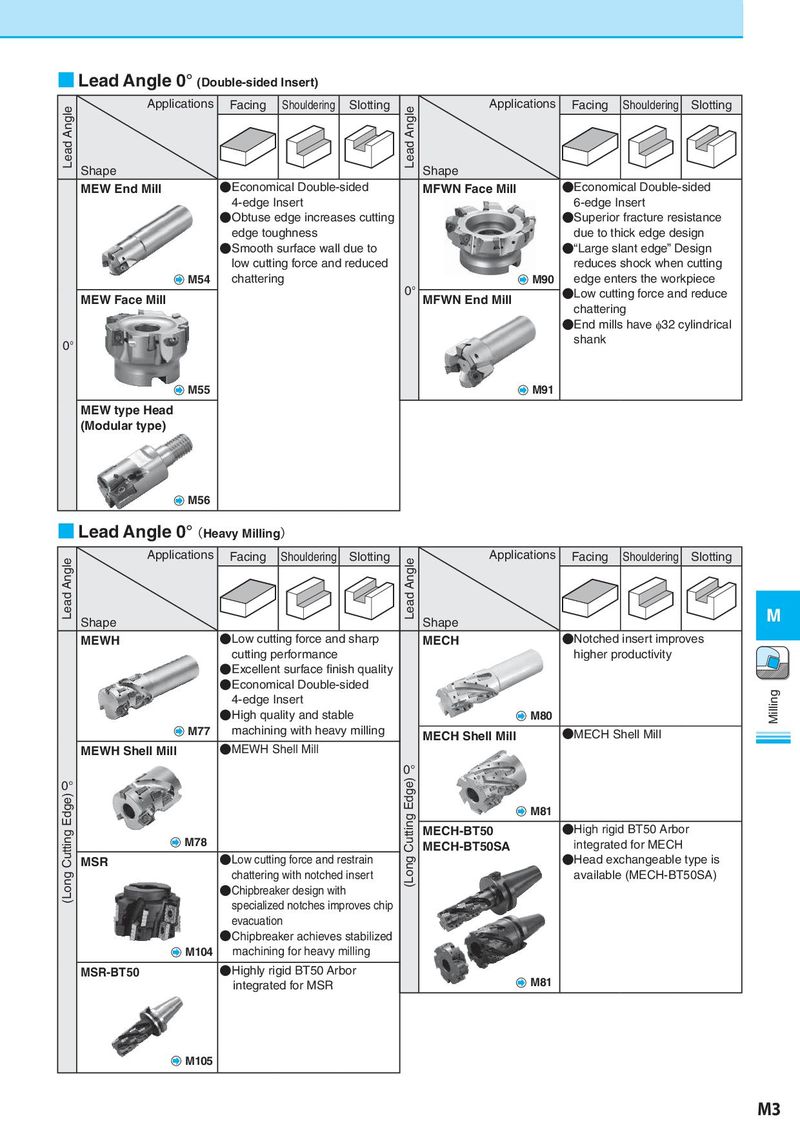

■ Lead Angle 0° (Double-sided Insert) Lead Angle Applications Facing Shouldering Slotting Lead Angle Applications Facing Shouldering Slotting Shape Shape MEW End Mill ●Economical Double-sided MFWN Face Mill ●Economical Double-sided 4-edge Insert 6-edge Insert ●Obtuse edge increases cutting ●Superior fracture resistance edge toughness due to thick edge design ●Smooth surface wall due to ●“Large slant edge” Design low cutting force and reduced reduces shock when cutting M54 chattering M90 edge enters the workpiece MEW Face Mill 0° MFWN End Mill ●Low cutting force and reduce chattering ●End mills have φ32 cylindrical 0° shank M55 M91 MEW type Head (Modular type) M56 ■ Lead Angle 0°(Heavy Milling) Lead Angle Applications Facing Shouldering Slotting Lead Angle Applications Facing Shouldering Slotting Shape Shape M MEWH ●Low cutting force and sharp MECH ●Notched insert improves cutting performance higher productivity ●Excellent surface finish quality ●Economical Double-sided Milling 4-edge Insert ●High quality and stable M80 M77 machining with heavy milling MECH Shell Mill ●MECH Shell Mill MEWH Shell Mill ●MEWH Shell Mill 0° 0° (Long Cutting Edge) (Long Cutting Edge) M81 MECH-BT50 ●High rigid BT50 Arbor M78 MECH-BT50SA integrated for MECH MSR ●Low cutting force and restrain ●Head exchangeable type is chattering with notched insert available (MECH-BT50SA) ●Chipbreaker design with specialized notches improves chip evacuation ●Chipbreaker achieves stabilized M104 machining for heavy milling MSR-BT50 ●Highly rigid BT50 Arbor integrated for MSR M81 M105 M3