Основной каталог Kyocera 2016-2017 - страница 690

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

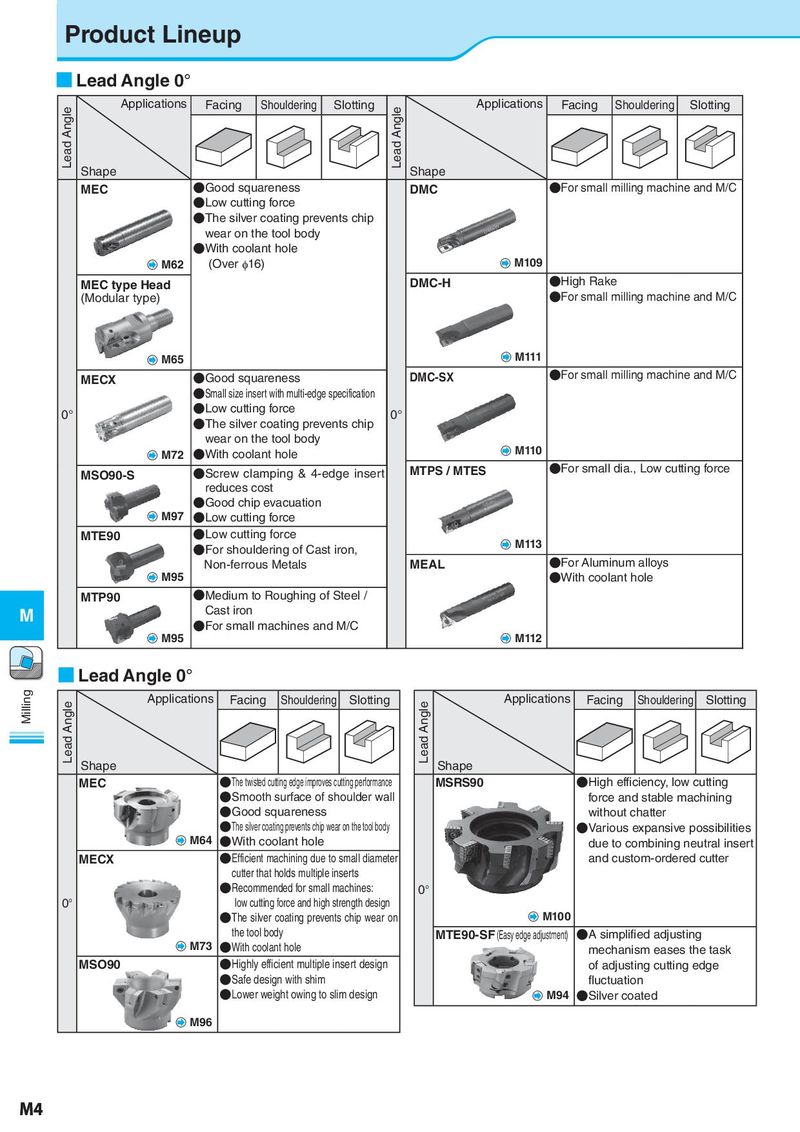

Product Lineup ■ Lead Angle 0° Lead Angle Applications Facing Shouldering Slotting Lead Angle Applications Facing Shouldering Slotting Shape Shape MEC ●Good squareness DMC ●For small milling machine and M/C ●Low cutting force ●The silver coating prevents chip wear on the tool body ●With coolant hole M62 (Over φ16) M109 MEC type Head DMC-H ●High Rake (Modular type) ●For small milling machine and M/C M65 M111 MECX ●Good squareness DMC-SX ●For small milling machine and M/C ●Small size insert with multi-edge specification 0° ●Low cutting force 0° ●The silver coating prevents chip wear on the tool body M72 ●With coolant hole M110 MSO90-S ●Screw clamping & 4-edge insert MTPS / MTES ●For small dia., Low cutting force reduces cost ●Good chip evacuation M97 ●Low cutting force MTE90 ●Low cutting force M113 ●For shouldering of Cast iron, Non-ferrous Metals MEAL ●For Aluminum alloys M95 ●With coolant hole MTP90 ●Medium to Roughing of Steel / M Cast iron ●For small machines and M/C M95 M112 ■ Lead Angle 0° Milling Lead Angle Applications Facing Shouldering Slotting Lead Angle Applications Facing Shouldering Slotting Shape Shape MEC ●The twisted cutting edge improves cutting performance MSRS90 ●High efficiency, low cutting ●Smooth surface of shoulder wall force and stable machining ●Good squareness without chatter ●The silver coating prevents chip wear on the tool body ●Various expansive possibilities M64 ●With coolant hole due to combining neutral insert MECX ●Efficient machining due to small diameter and custom-ordered cutter cutter that holds multiple inserts ●Recommended for small machines: 0° 0° low cutting force and high strength design ●The silver coating prevents chip wear on M100 the tool body MTE90-SF (Easy edge adjustment) ●A simplified adjusting M73 ●With coolant hole mechanism eases the task MSO90 ●Highly efficient multiple insert design of adjusting cutting edge ●Safe design with shim fluctuation ●Lower weight owing to slim design M94 ●Silver coated M96 M4